Device for scattering bulk material

A technology for loose materials and equipment, which is applied in the field of equipment for dispersing loose materials, can solve problems such as high cost, troublesome research, and impossibility, and achieve the effects of avoiding adhesion, optimizing distribution performance, and small delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

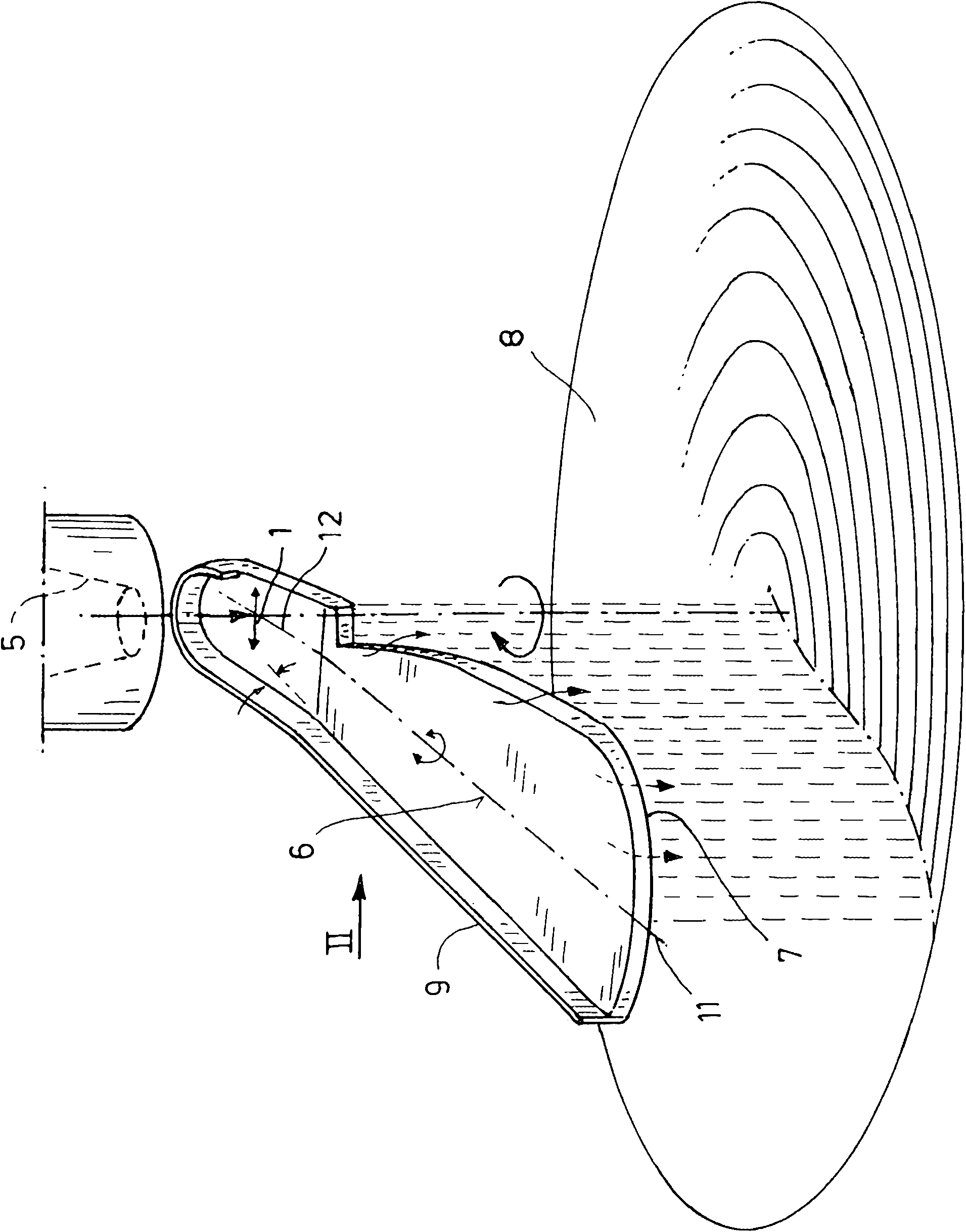

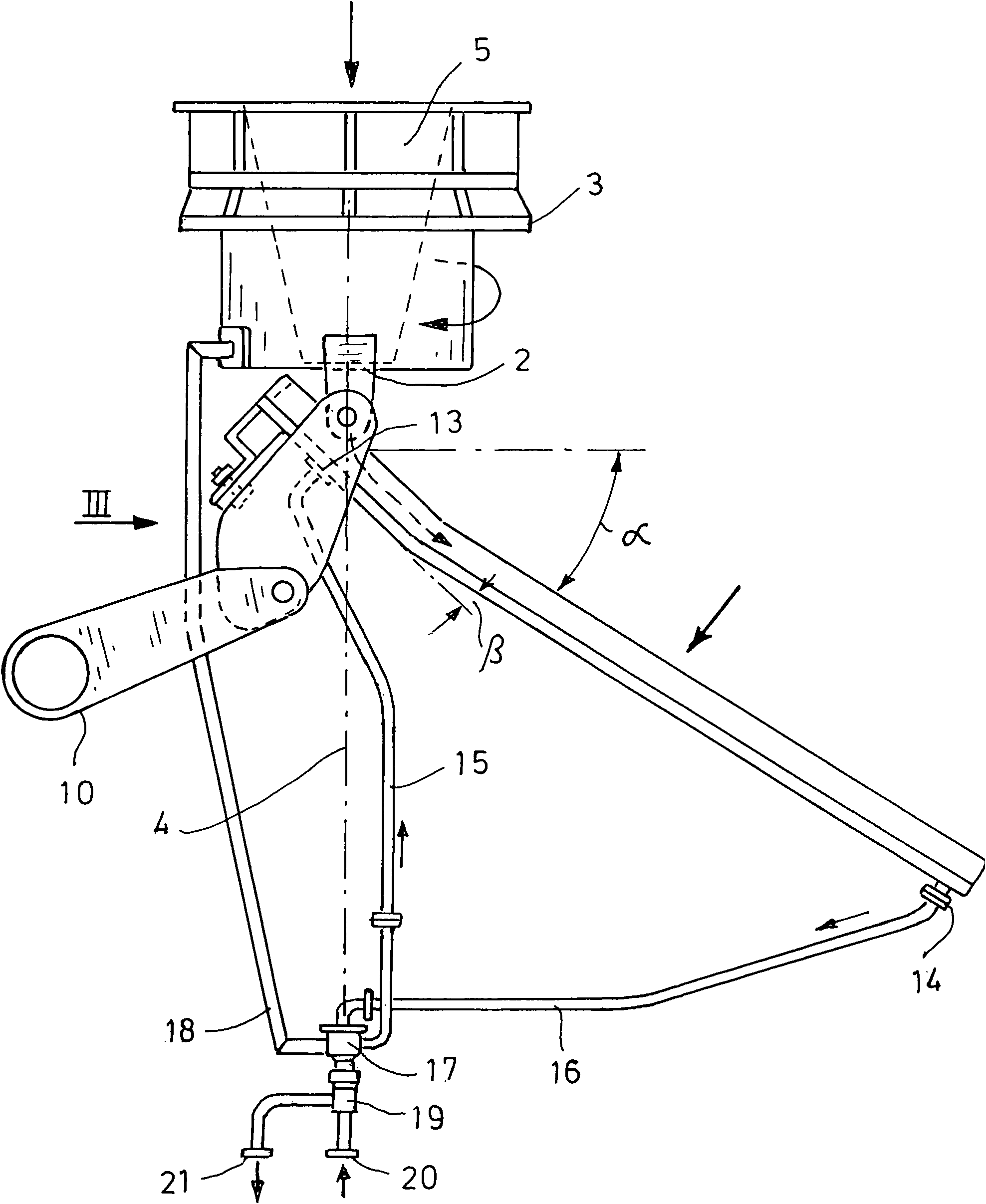

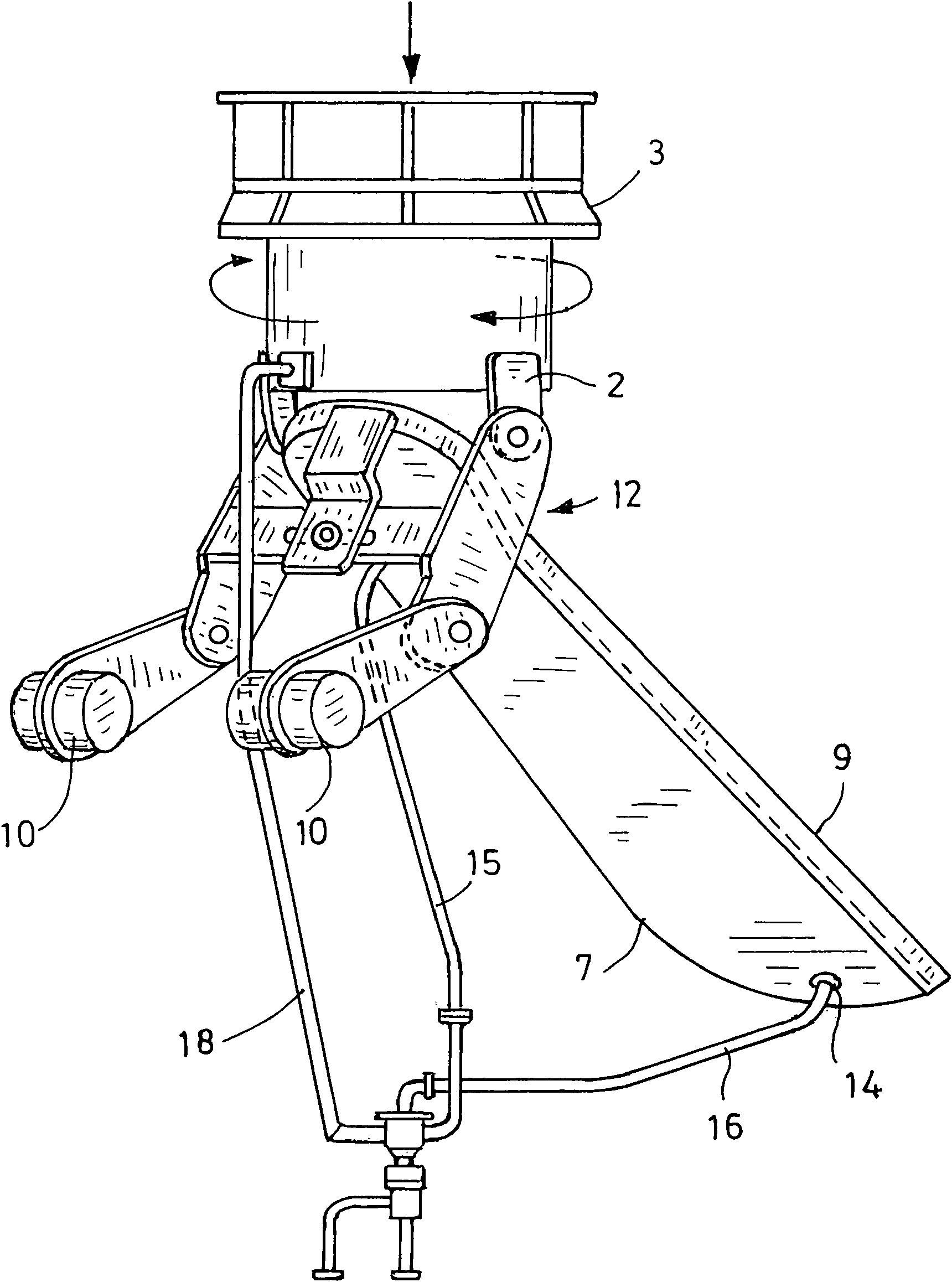

[0024] First refer to the following figure 2 and 3 . The device according to the invention comprises a distribution slide, designated 1 , which is rigidly connected via a holding bracket 2 to a rotating flange 3 . The rotary flange is provided with drive means, not shown, by means of which it is regularly rotated with the distribution slide 1 fastened thereto about the vertical axis 4 . For this purpose, the rotary flange 3 can be provided with a circumferential toothing, not shown, which interacts with the drive pinion of the electric motor. The direction of rotation of the device is in Figures 1 to 3 Arrows drawn in indicate. In the illustrated embodiment, the distribution chute 1 rotates in a clockwise direction.

[0025] Arranged centrally within the swivel flange 3 above the distribution chute 1 is an inlet chute 5 via which pourable material, for example moist raw lignite, is fed onto the distribution chute 1 .

[0026] The longitudinal center axis of the feed ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap