Device for measuring carbon content of fly ash in boiler of electric power plant

A fly ash carbon content, boiler technology, applied in the direction of measuring devices, material analysis using microwave means, instruments, etc., to achieve the effect of improving measurement accuracy, reasonable structure design, and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

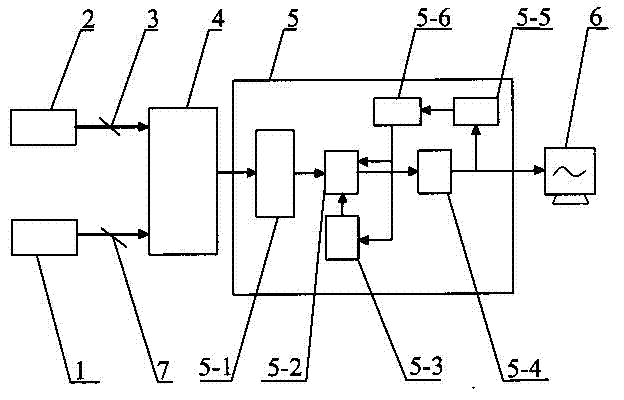

[0011] according to Figure 1~3 The specific structure and working process of the present invention will be described in detail. The power plant boiler fly ash carbon content measuring device includes the following parts: flue working state unit 1, boiler working state unit 2, first and second data buses 3 and 7, data input unit 4, computer-controlled fly ash carbon content Analysis unit 5 and alarm display unit 6 and other components. in:

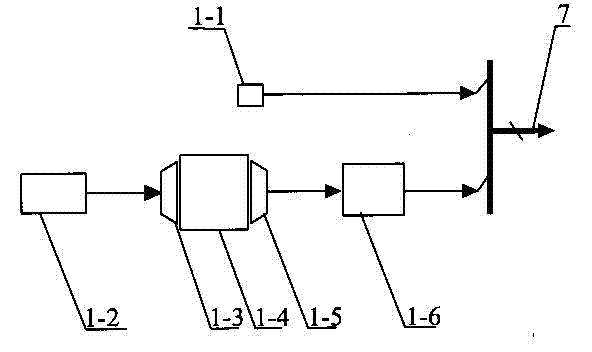

[0012] The flue working state unit 1 installed on the boiler flue of the power plant is used to collect the oxygen content of the flue gas at the furnace outlet and the microwave power, including the oxygen content sensor 1-1 of the flue gas at the furnace outlet, the microwave signal source 1-2, and the microwave transmitter. Terminal 1-3, microwave receiving terminal 1-5, microwave power detector 1-6 and other components.

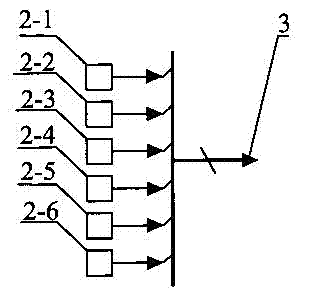

[0013] The collection of boiler load, primary air pressure, secondary air pressure, burner pulverized coal flow,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com