Test bench for X-ray detection apparatuses

A flaw detector and X-ray technology, which is applied in the field of X-ray flaw detector detection test bench, can solve the problems of expensive instruments, difficult operation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

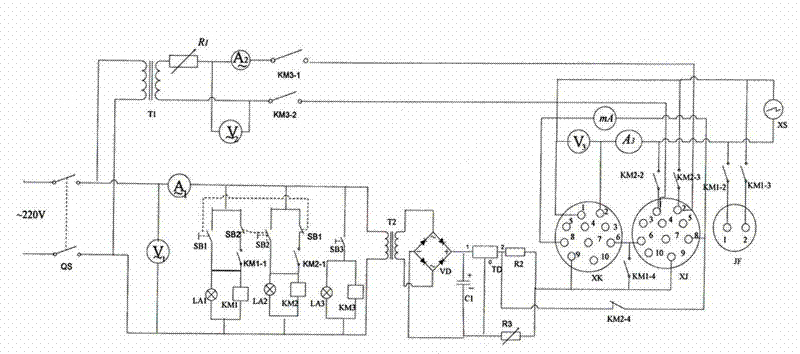

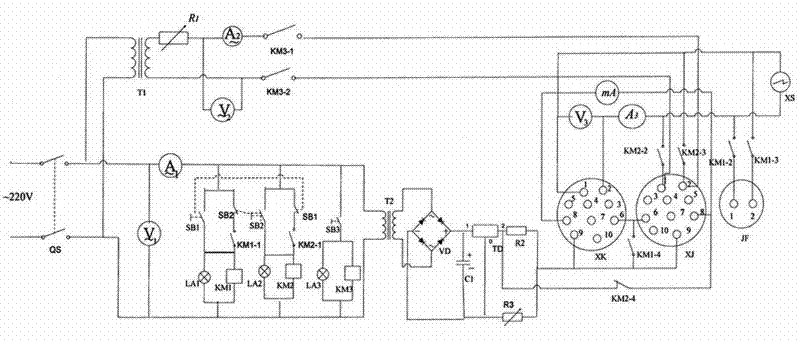

[0008] Referring to the accompanying drawings, the 220V mains is connected to the power terminal through the air switch QS, and the power terminal is connected to the control voltmeter V in parallel. 1 , Series control ammeter A 1 After forming the control power supply, it consists of three AC relays KM 1 、KM 2 、KM 3 and three sets of pushbutton switches SB 1 , SB 2 , SB 3 The control circuit is composed of the starting transformer T 2 , rectification filter voltage stabilization circuit, voltage divider circuit to form the starting circuit, control circuit and starting transformer T 2 Connect to the control power supply, button switch one SB 1 The normally open contacts are connected in series with the AC relay-KM 1 , Push button switch 2 SB 2 The normally open contacts are connected in series with the AC relay II KM 2 , push button switch three SB 3 Series connection AC relay three KM 3 Then respectively connected to both ends of the control power supply, AC rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com