Dye colour trying machine

A color testing machine and dye technology, which is applied in the field of dye color testing machines, can solve problems such as waste, affecting production efficiency, and scrapping, and achieve the effects of avoiding waste, saving production costs, and preventing non-compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

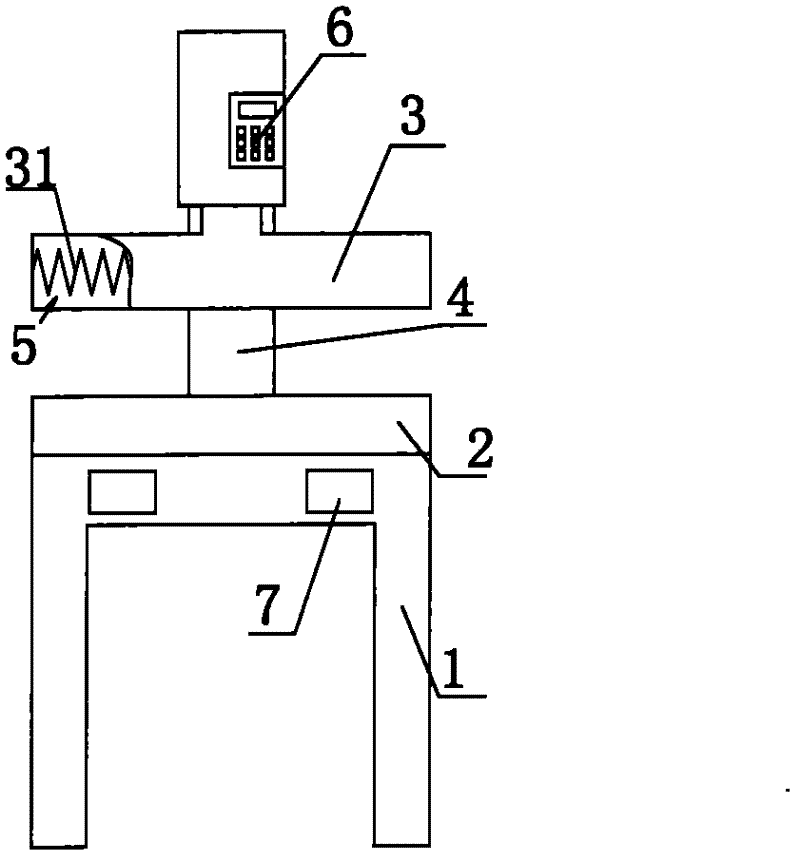

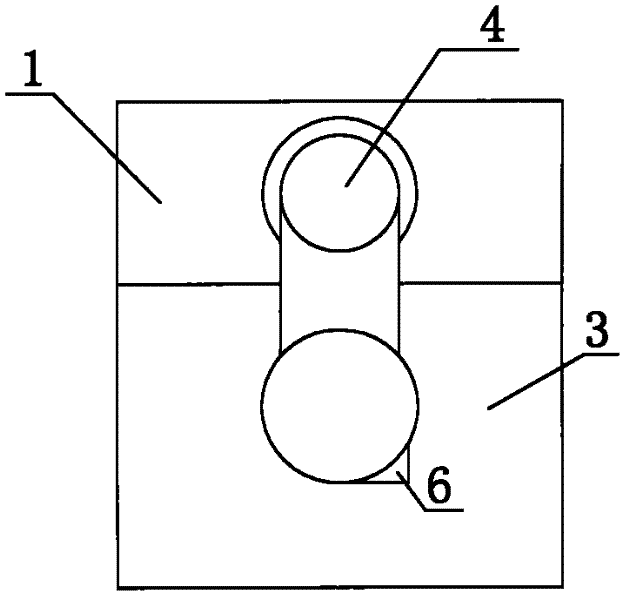

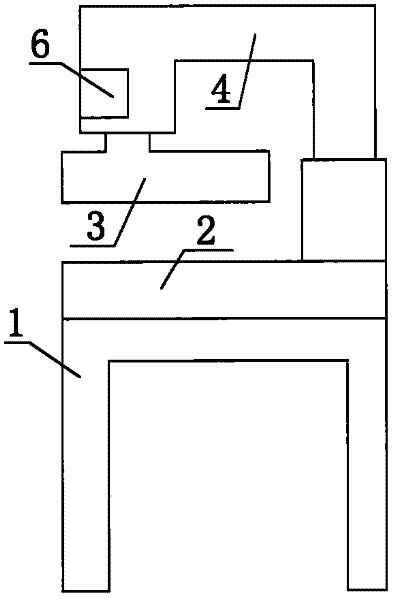

[0016] Such as figure 1 As shown, the dye color testing machine is used to print the color on the dyed paper onto the cloth so as to observe the color of the prepared dye. It includes a frame 1, a base 2 fixed horizontally on the frame 1, a parallel The pressing plate 3 on the base 2 and directly above the base 2 , the hydraulic arm 4 fixed on the frame 1 and connected to the upper surface of the pressing plate 3 .

[0017] The frame is provided with a switch button 7 for controlling the hydraulic arm 4. By controlling the switch button 7, the hydraulic arm is controlled to move up and down, and the hydraulic arm 4 drives the pressing plate 3 to move up and down.

[0018] The pressing plate 3 is made of stainless steel, and a heating device 5 for heating the pressing plate 3 is arranged inside, and the heating device 5 includes a resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com