Double-faced dry laminating combination machine for woven bag, and laminating method

A woven bag and combined machine technology, which is applied in the field of dry laminating machines, can solve the problems of dislocation of text and/or pattern information, low efficiency of single-sided laminating, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

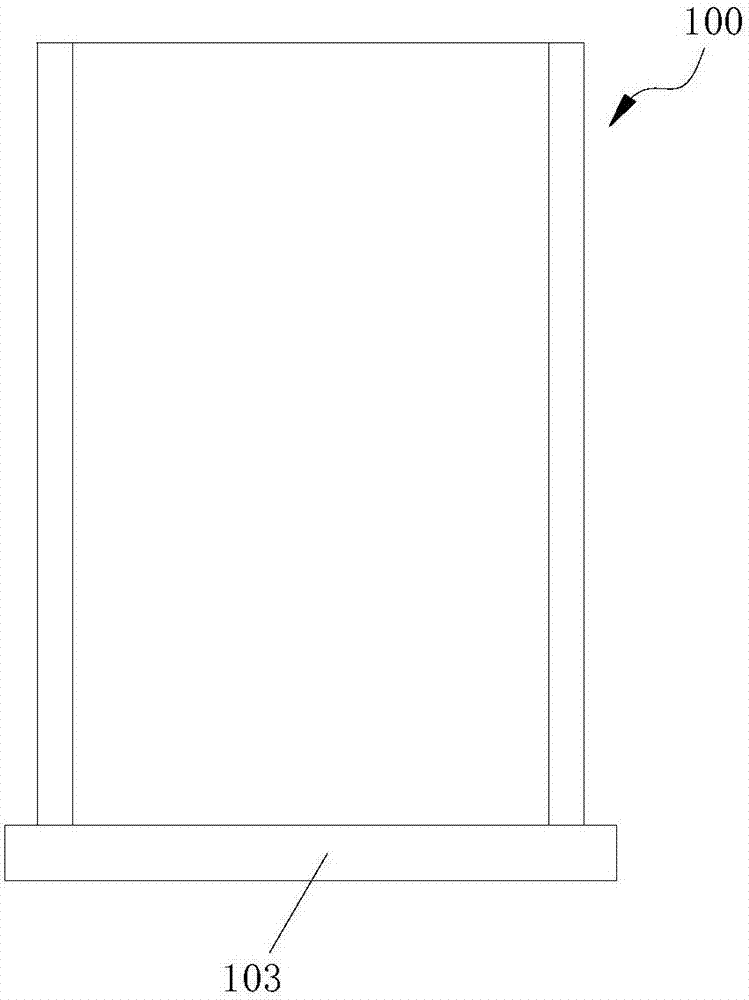

[0039] Such as figure 1 As shown, a woven bag of the present invention, the woven bag 100 is laminated on both sides, the bottom is sealed with a seal 103, and there is no text and / or pattern information 101 on the film.

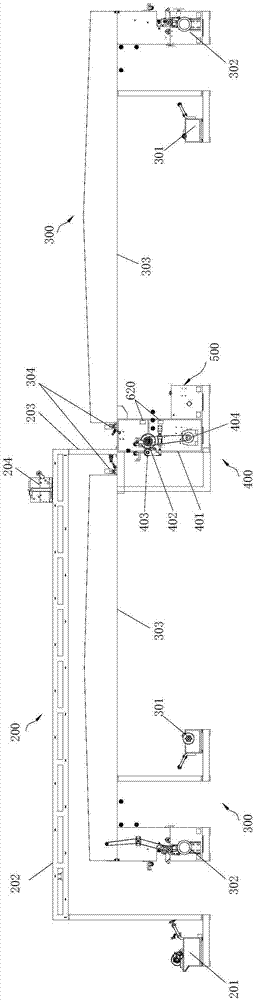

[0040] Such as Figure 3-Figure 4 As shown, a woven bag double-sided dry-type laminating machine includes a woven bag feeding mechanism 200 for conveying the woven bag 100, a film feeding mechanism 300 for conveying the film, and a film feeding mechanism 300 for laminating the film on the woven bag. The dry compounding mechanism 400 on 100, the rolling mechanism 500 for the retroperitoneal woven bag 100 rolling and the feeding mechanism 200 for controlling the woven bag, the film feeding mechanism 300, the dry compounding mechanism 400, the winding mechanism 500 and the compounding mechanism The controller of the film calibration mechanism 600 working together. The film feeding mechanism 300 is divided into two groups, which are symmetrically arranged on bo...

Embodiment 2

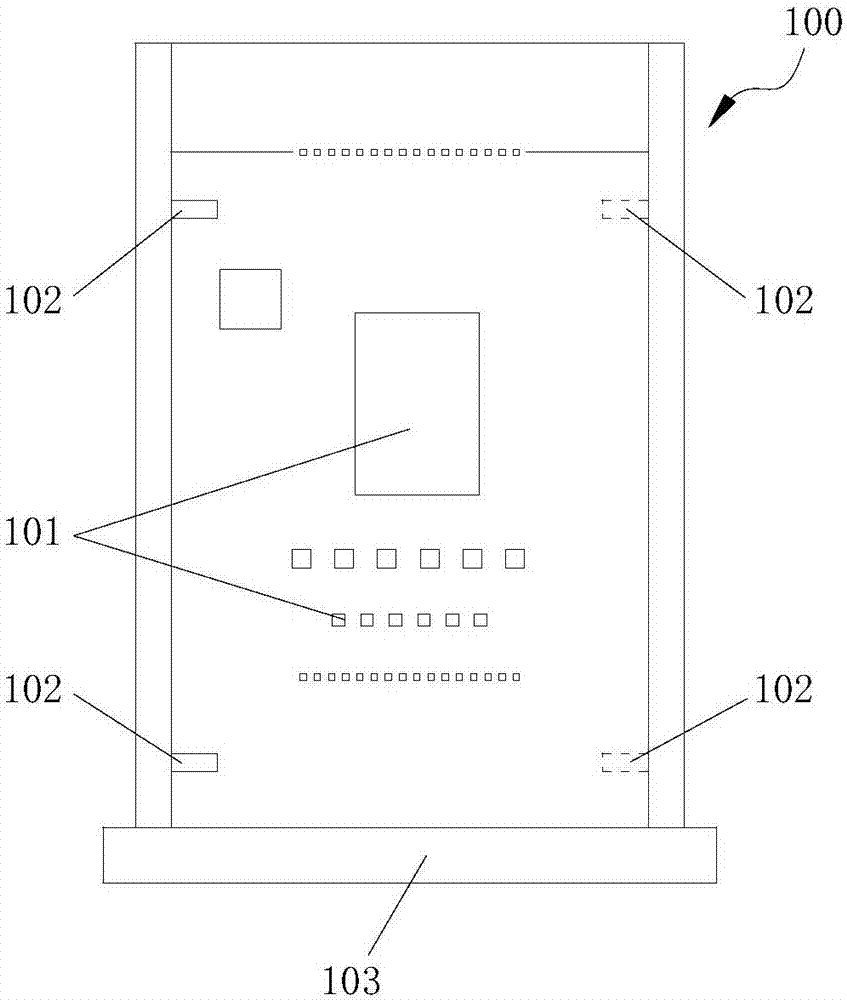

[0046] This embodiment is mainly aimed at the situation that both sides of the film with text and / or pattern information 101 are laminated simultaneously. Such as figure 2 As shown, a woven bag of the present invention, the woven bag 100 is laminated on both sides, the bottom is sealed with a seal 103, and the same text and / or pattern information 101 is arranged at equal intervals on the film used for laminating, and each The position corresponding to the group text and / or pattern information 101 is provided with an alignment mark 102. In the figure, the solid line represents the alignment mark 102 on the front side, and the dotted line represents the alignment mark 102 on the reverse side. The alignment mark 102 described in this embodiment is a color code The film on each side is provided with two color codes, one is located on the upper part of the text and / or pattern information 101, and the other is located on the lower part of the text and / or pattern information 101. T...

Embodiment 3

[0056] This embodiment is mainly aimed at the situation that both sides of the film with text and / or pattern information 101 are laminated simultaneously. Such as figure 2As shown, a woven bag of the present invention, the woven bag 100 is laminated on both sides, the bottom is sealed with a seal 103, and the same text and / or pattern information 101 is arranged at equal intervals on the film used for laminating, and each The position corresponding to the group text and / or pattern information 101 is provided with an alignment mark 102. In the figure, the solid line represents the alignment mark 102 on the front side, and the dotted line represents the alignment mark 102 on the reverse side. The alignment mark 102 described in this embodiment is a color code The film on each side is provided with two color codes, one is located on the upper part of the text and / or pattern information 101, and the other is located on the lower part of the text and / or pattern information 101. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com