Method for detecting friction plate abrasion of electronic parking braking system

An electronic parking brake and detection method technology, applied in the direction of measuring device, using electric device, using electromagnetic means, etc., can solve the problem of difficult large-scale high-efficiency production and manufacturing, inability to adapt to the improvement of existing models, and inappropriate friction plate detection structure. Accuracy and other issues, to achieve the effect of easy improvement, convenient improvement and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution provided by the present invention is a method for detecting friction lining wear of an electronic parking brake system. The steps of the detection method are as follows:

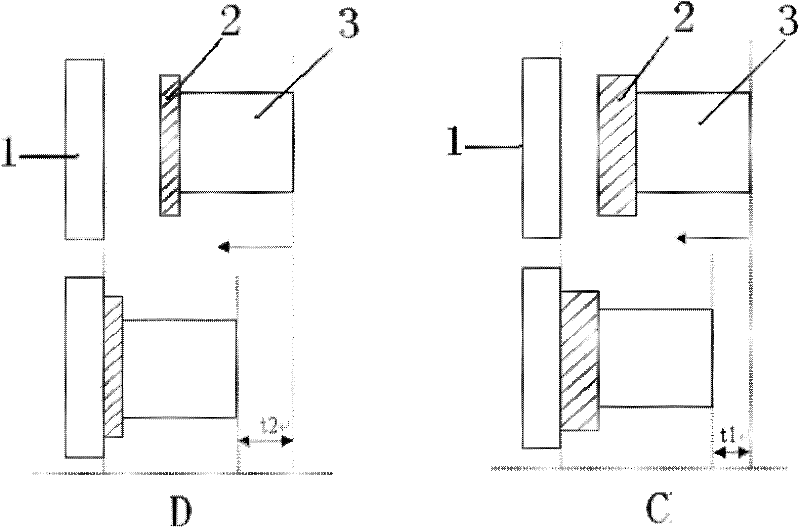

[0024] The first step is to brake the vehicle through the electronic parking brake system, and control the actuator to clamp the friction plate 2;

[0025] In the second step, the vehicle-mounted electronic control unit 6 (ECU) detects the variation of the voltage, current and time of the clamping process of the control actuator;

[0026] In the third step, the vehicle-mounted electronic control unit 6 (ECU) obtains the wear amount of the detected friction plate 2 through logical judgment on the above-mentioned change amount obtained.

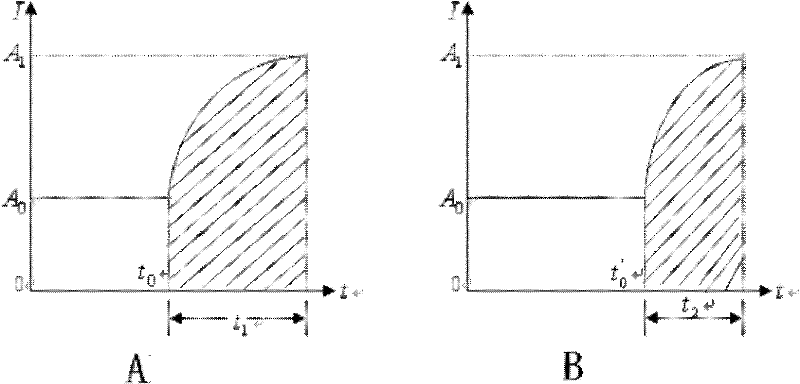

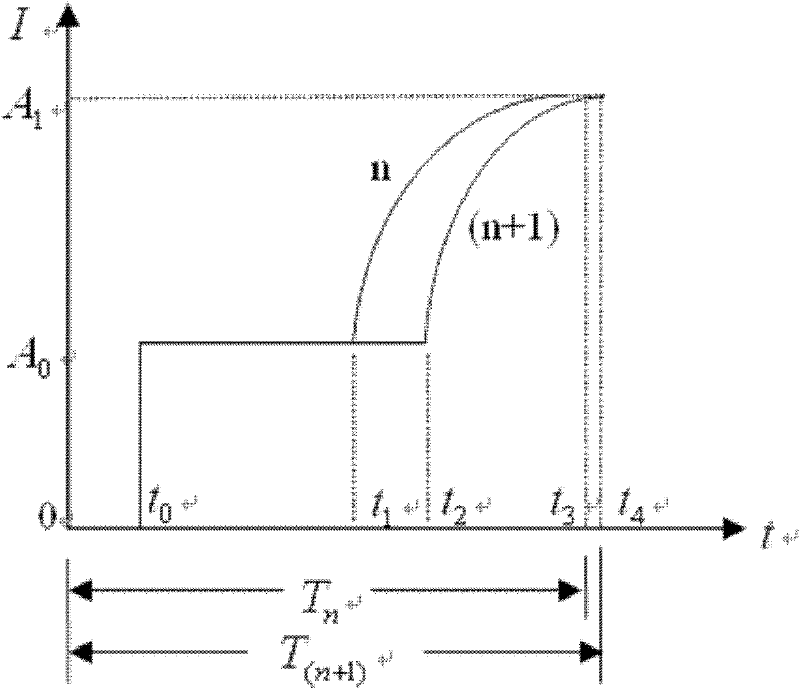

[0027] The vehicle-mounted electronic control unit 6 (ECU) measures the variation of the voltage, current and time measured by the actuator during the parking process, according to the compression amount of the friction plate 2 and the voltage an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com