Component-type external wall thermal insulation decorative board and its manufacturing method and external wall installation method

A technology of external wall insulation and installation method, which is applied in the direction of building construction, covering/lining, construction, etc., can solve the problems of high equipment rental and management costs, poor durability of the overall surface layer, and long construction period, so as to reduce labor intensity High degree of operation, high degree of operation, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings of the description.

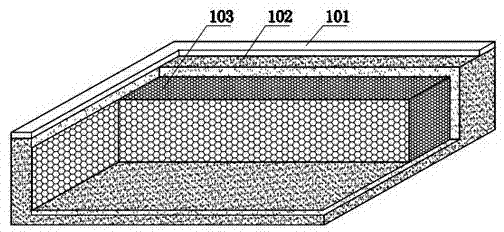

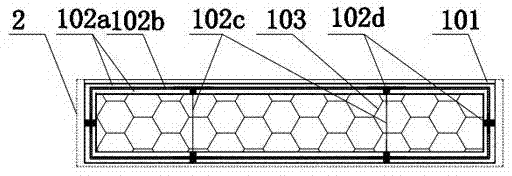

[0051] As shown in the figure, the component-type exterior wall thermal insulation decorative panel consists of a decorative surface layer 101, a rigid layer 102, and an insulation layer 103 to form a component-type panel 1. The insulation layer 103 is wrapped with a rigid layer 102, and the upper surface of the rigid layer 102 is matched with a decoration. Surface 101. The component plate 1 is a rectangular flat body structure, and the four sides or two sides of the component plate 1 are provided with chamfers 104 and semicircular grooves 105 . Embossing or engraving 106 is provided on the panel surface of the component panel 1 . The thermal insulation layer 103 is made of but not limited to perlite particle boards, foamed cement boards or rock wool boards; the decorative surface layer 101 is made of but not limited to veneer block materials, polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com