Automatic stamp making machine for paper official document

A seal machine and official document technology, applied in printing, stamping, etc., can solve the problems of stamping seal clarity, position accuracy and consistency, low operation efficiency, high labor intensity, etc., and achieve simple structure and high operation efficiency , good quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

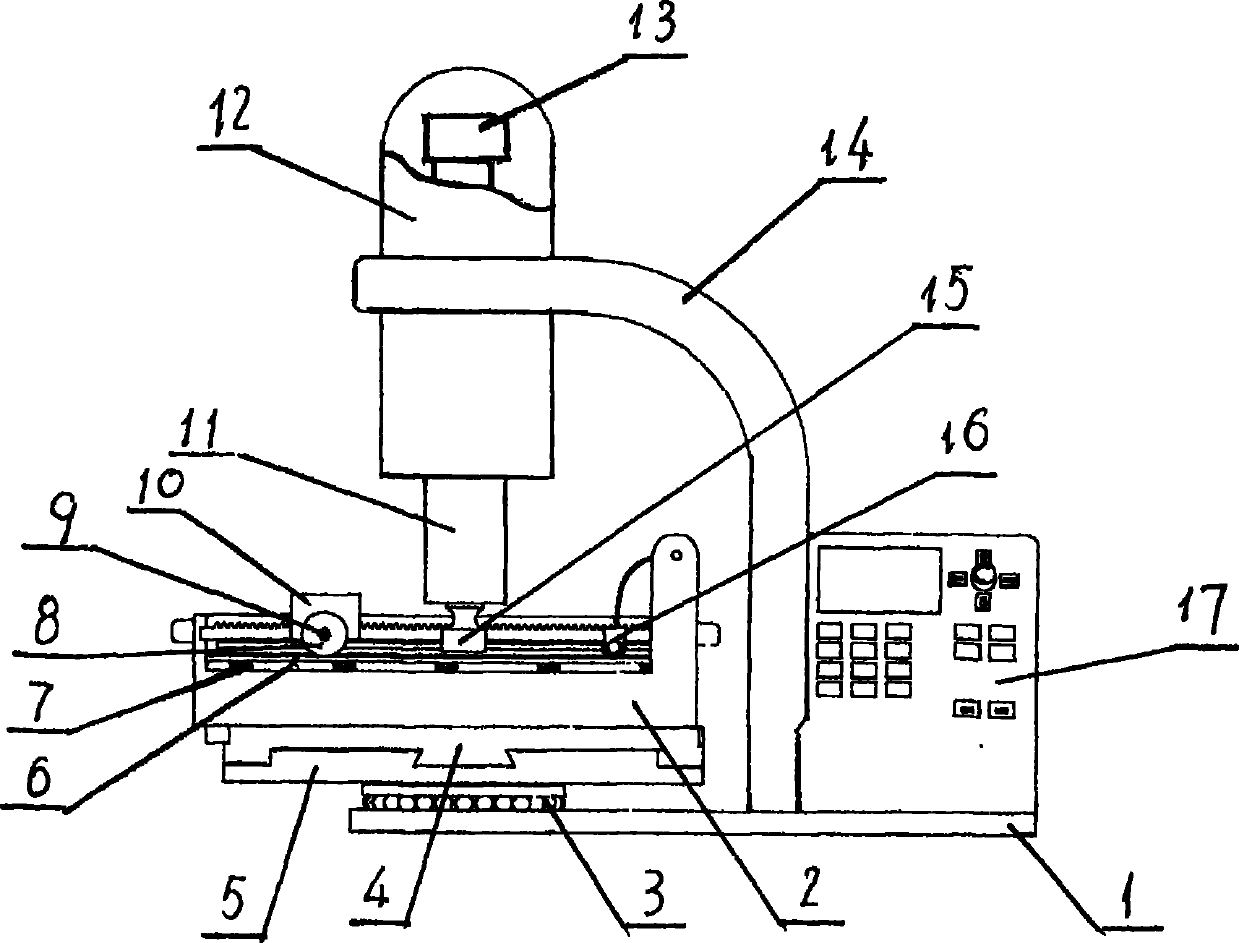

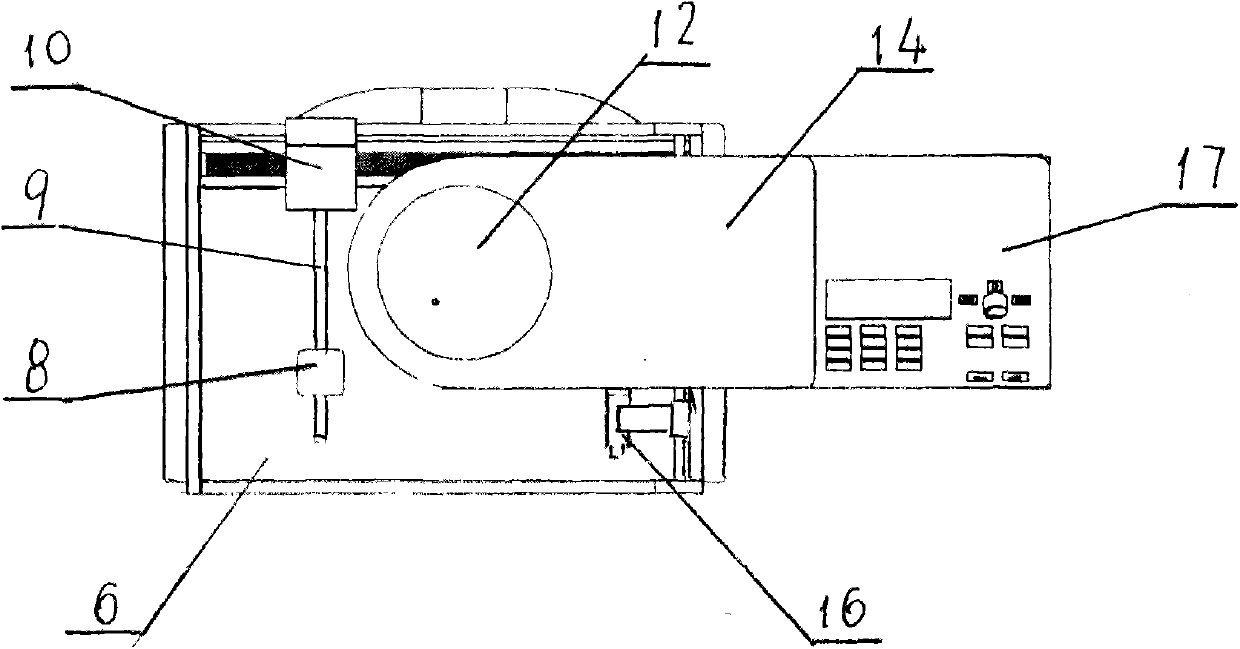

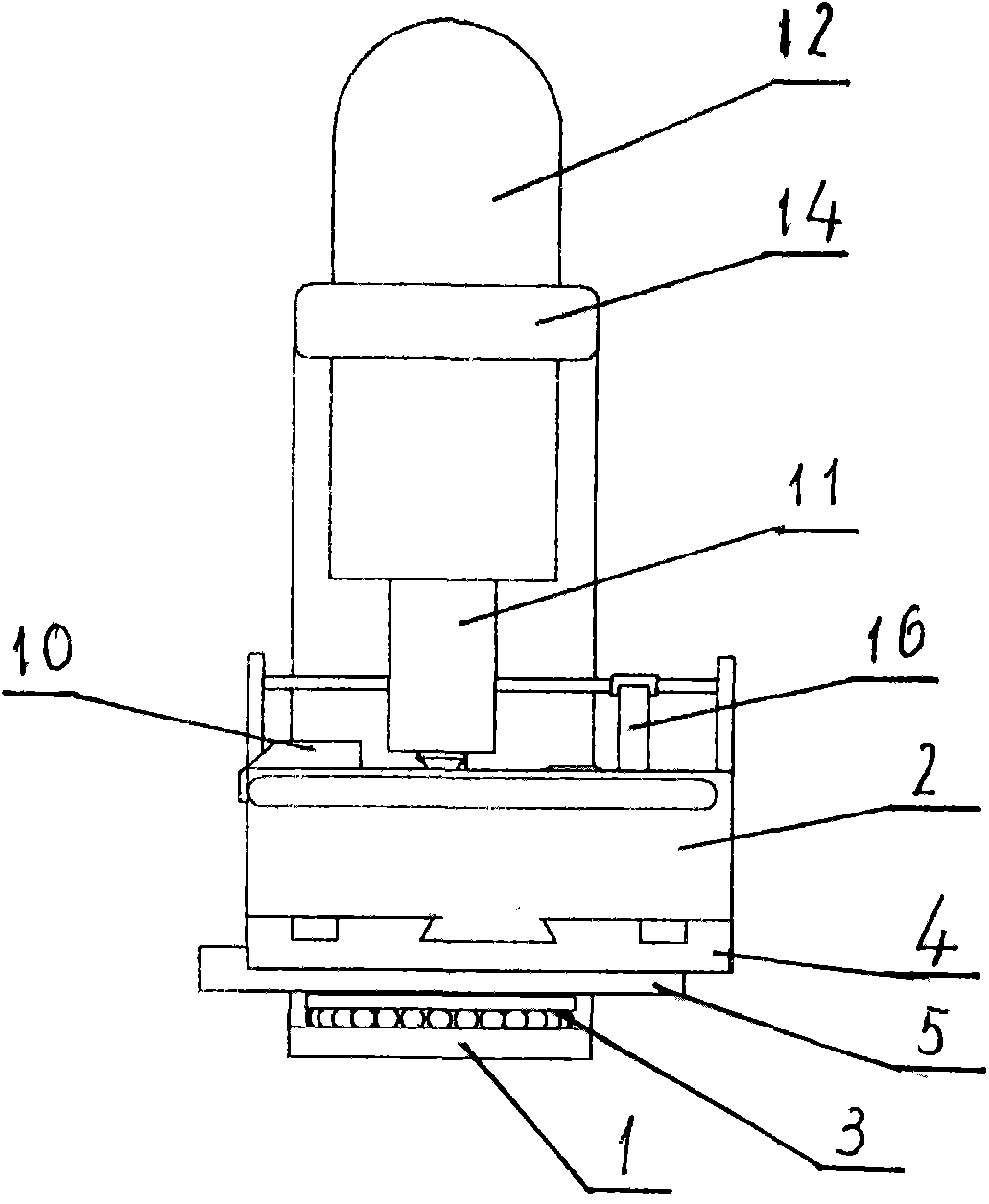

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An automatic stamping machine for paper official documents. A small computer 17, an installation frame 14 and a plane ball bearing 3 are sequentially assembled on a base plate 1, and a lower plate 5 is fitted on the plane ball bearing 3. Equipped with the middle plate 4, the upper plate 2 can be adjusted and moved on the middle plate 4. The moving direction of the middle plate 4 on the lower plate 5 is perpendicular to the moving direction of the upper plate 2 on the middle plate 5. The upper plate 2 is supported by the pressure spring 7 to support the paper supporting plate 6, the first micro motor 10 and the paper pressing roller 16 equipped with the drive shaft 9 are installed on the upper plate 2, and the paper pick-up rubber roller 8 is fixed on the drive shaft 9 , the telescopic mechanism 12 with the up and down moving shaft 11 and the second micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com