Wire drawing die for welding wires

A wire drawing and eye mold technology, applied in the direction of wire drawing dies, etc., can solve the problem that the eye mold is difficult to obtain satisfactory results, and achieve the effects of uniform plastic deformation, high cleanliness, and straight weld bead.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

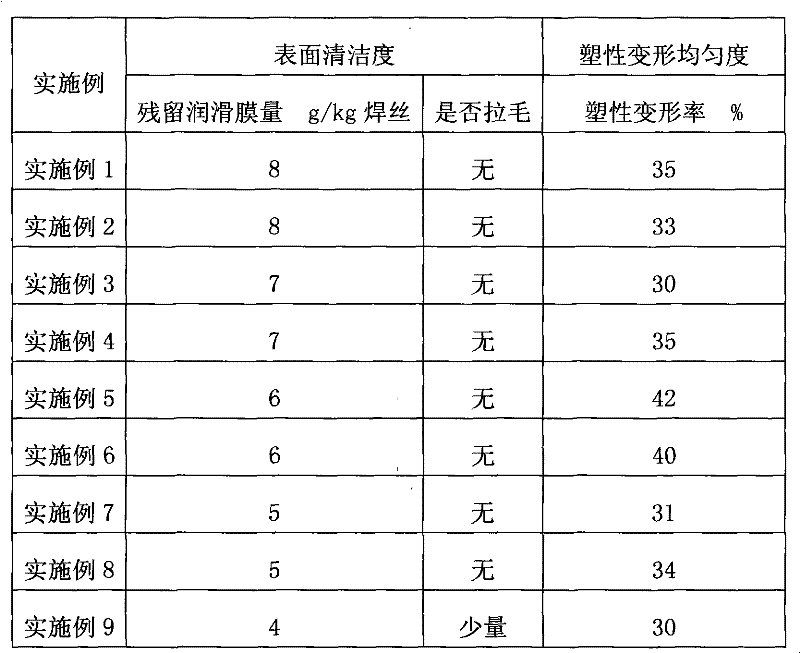

Examples

Embodiment

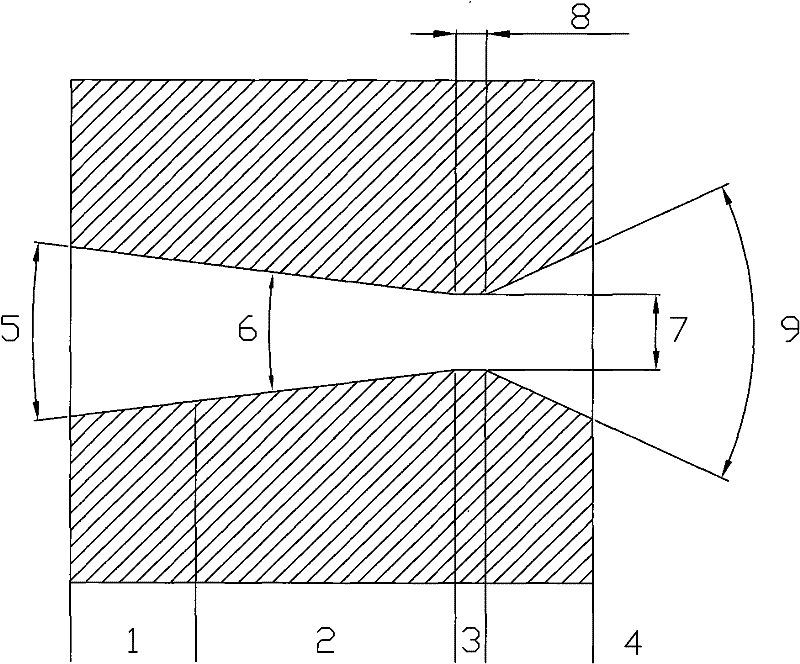

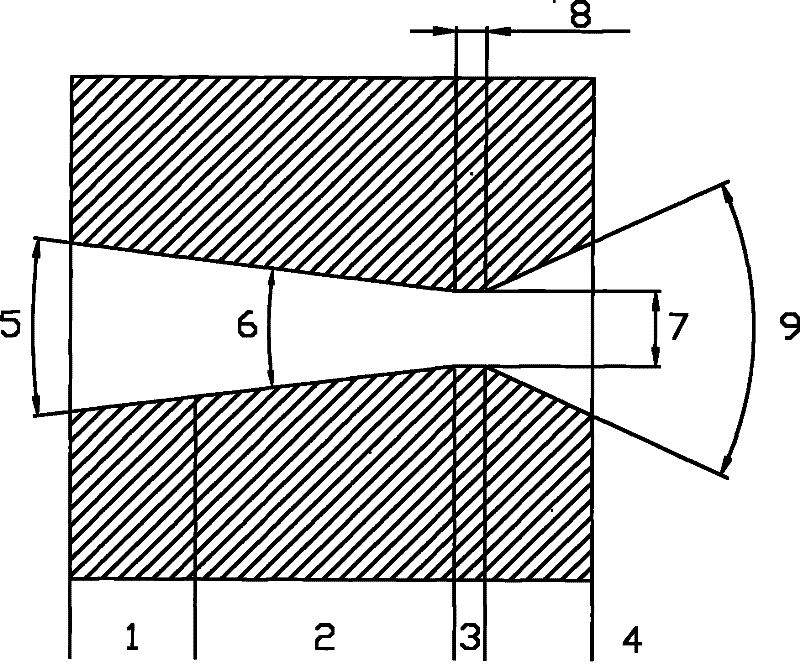

[0008] Embodiment: A wire drawing eye mold for welding wire, the inner hole of the mold core is provided on the wire drawing eye mold, and the inner hole of the mold core is composed of an entry zone 1, a compression zone 2, a sizing zone 3 and a release zone 4, An entry angle 5, a compression angle 6, and a release angle 9 are provided corresponding to the entry area, compression area and release area, and a sizing diameter 7 and a sizing length 8 are set on the corresponding sizing area, and the range of the compression angle 6 is 10 °-16°, the ratio of the sizing length 8 to the sizing diameter 7 ranges from 30% to 45%.

[0009] The angle of the entry angle 5 is equal to the angle of the compression angle, which prevents the lubricating powder from entering the entry area, being blocked by the compression angle in the compression area, and overflowing in reverse, so that the lubricating powder can fully enter. The range of the release angle 9 30°-70°.

[0010] Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com