A kind of processing method of seamless pipe welding wire containing rutile flux core powder prepared by low carbon steel strip

A processing method and rutile technology, which are applied in metal processing equipment, manufacturing tools, welding media, etc., can solve the problems of inability to achieve continuous production, uneven welding wire composition, and easy occurrence of powder layering, etc., to achieve good welding processability, Improved wire feed performance and wire alignment, resulting in overall cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

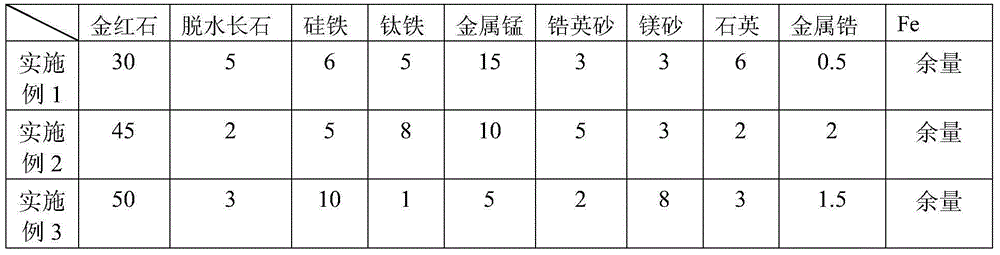

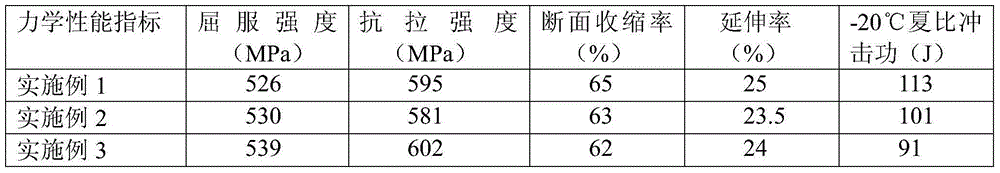

[0034] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0035] Rutile is the main slagging agent and arc stabilizer, which can adjust the melting point and viscosity of welding slag, improve the forming and slag removal of weld seam, and the addition amount is preferably 30-50%.

[0036] Na in dehydrated feldspar 2 O and K 2 O can improve the stability of the arc and play a role in stabilizing the arc. SiO in dehydrated feldspar 2 and Al 2 o 3 The viscosity of molten iron and slag can be adjusted, which is beneficial to all-position welding; but if the addition amount is too high, it will cause increased smoke and spatter, so the addition amount of dehydrated feldspar should be controlled between 2 and 5%.

[0037] The main purpose of addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com