Surface coating material for copper-plating-free welding wire and preparation method and application thereof

A surface coating and copper-free technology, which is applied in welding/cutting media/materials, welding equipment, welding media, etc., can solve problems such as poor anti-rust performance of non-copper-coated welding wire, wear and conductivity of contact tips, etc. , to achieve the effect of improving the rust resistance, improving the grinding environment, and improving the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment provides a kind of surface coating material that is used for copper-free welding wire, comprises the following components by mass percentage: palm oil 88%, polytetrafluoroethylene 7%, nano-titanium dioxide 1.0%, tin oxide 1.2% , nano antimony powder 0.5%, potassium borate 2.3%. Among them, the diameter of polytetrafluoroethylene is controlled at 20 μm, and the size of nano-titanium dioxide and nano-antimony powder is controlled at about 150 nm.

[0026] Surface coating material preparation method: heat the base oil in a reactor at 100°C and stir for 30 minutes; place the remaining materials in a small powder shaker for 1 hour, put them into the reactor after being fully and uniformly mixed, and heat to 100°C ℃, stirred for 40 minutes and then stood still to make a surface coating material for non-copper-plated welding wire.

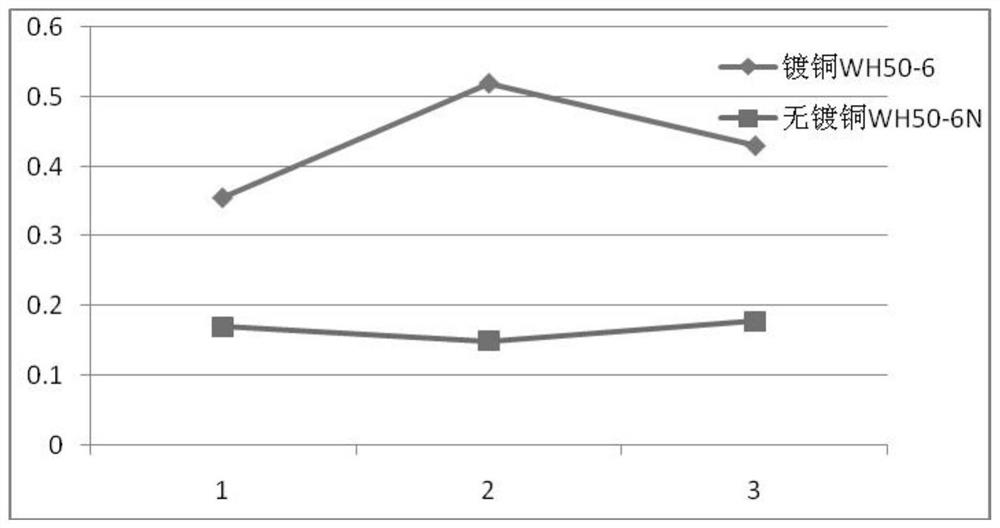

[0027] The surface coating material prepared above is coated on the surface of the welding wire substrate by neck reductio...

Embodiment 2

[0029] The present embodiment provides a kind of surface coating material that is used for copper-free welding wire, comprises the following components by mass percentage: palm oil 90%, polytetrafluoroethylene 4.5%, nano-titanium dioxide 1.5%, tin oxide 1.0% , nano antimony powder 0.5%, potassium carbonate 2.5%. Among them, the diameter of polytetrafluoroethylene is controlled at 15 μm, and the size of nano-titanium dioxide and nano-antimony powder is controlled at about 100 nm.

[0030] Surface coating material preparation method: put the base oil in the reactor, heat to 90°C, and stir for 30 minutes; place the rest of the materials in a small powder shaker for 1 hour, put them into the reactor after being fully and uniformly mixed, and heat to 90°C, stirred for 40 minutes and then left to stand to make a surface coating material for non-copper-plated welding wire.

[0031] The surface coating material prepared above is coated on the surface of the welding wire substrate by ...

Embodiment 3

[0033] The present embodiment provides a kind of surface coating material that is used for copper-free welding wire, comprises the following components by mass percentage: animal fat oil 85%, polytetrafluoroethylene 10%, nano-titanium dioxide 2%, tin oxide 0.9%, nano antimony powder 0.6%, potassium borate 1.0%, potassium carbonate 0.5%. Among them, the diameter of polytetrafluoroethylene is controlled at 10 μm, and the size of nano-titanium dioxide and nano-antimony powder is controlled at about 50 nm.

[0034] Surface coating material preparation method: put the base oil in the reactor, heat to 100°C, and stir for 30 minutes; place the rest of the materials in a small powder shaker for 1 hour, put them into the reactor after being fully and uniformly mixed, and heat to Stir at 100°C for 40 minutes and then stand still to make a surface coating material for copper-free welding wire.

[0035] The surface coating material prepared above is coated on the surface of the welding w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com