Printing defvice, method for controlling printing device, and computer program

A technology of printing device and control unit, applied in the direction of printing device, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0061] A-1. Configuration of printing device

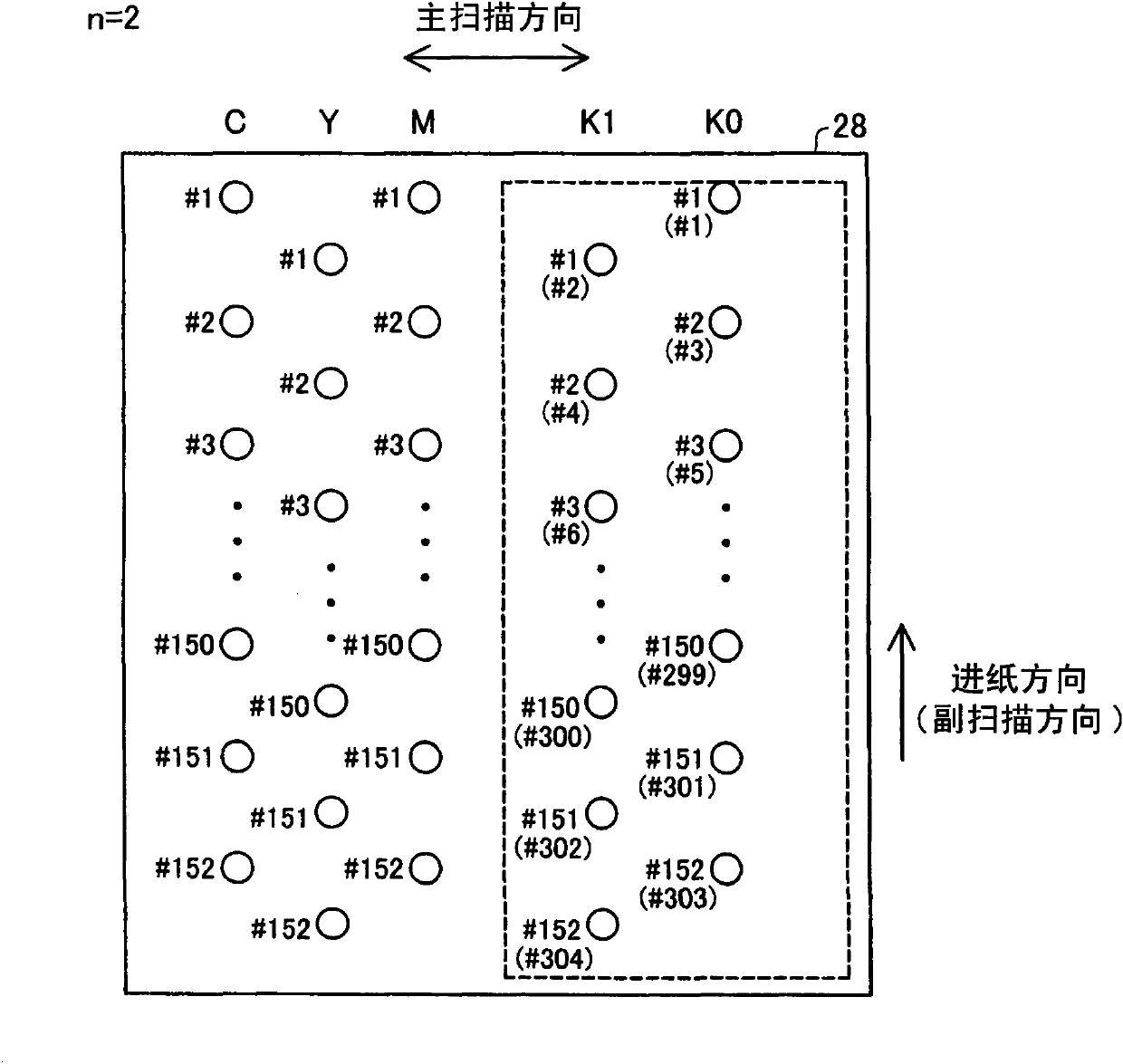

[0062] A-2. Recording method

no. 2 Embodiment

[0064] C. The third embodiment

[0065] D. Fourth embodiment

[0066] E. Variation

[0067] A. The first embodiment

[0068] A-1. Configuration of printing device

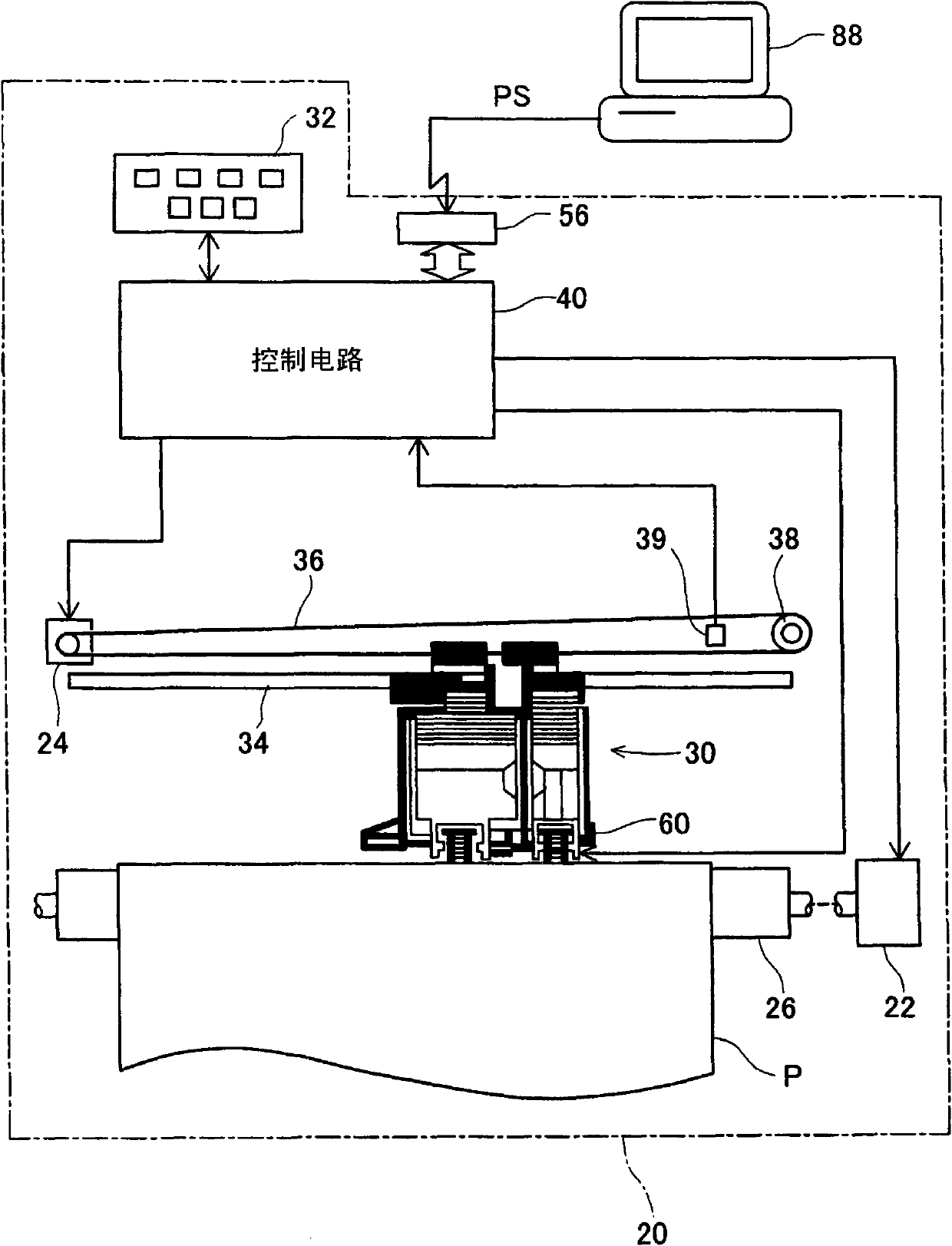

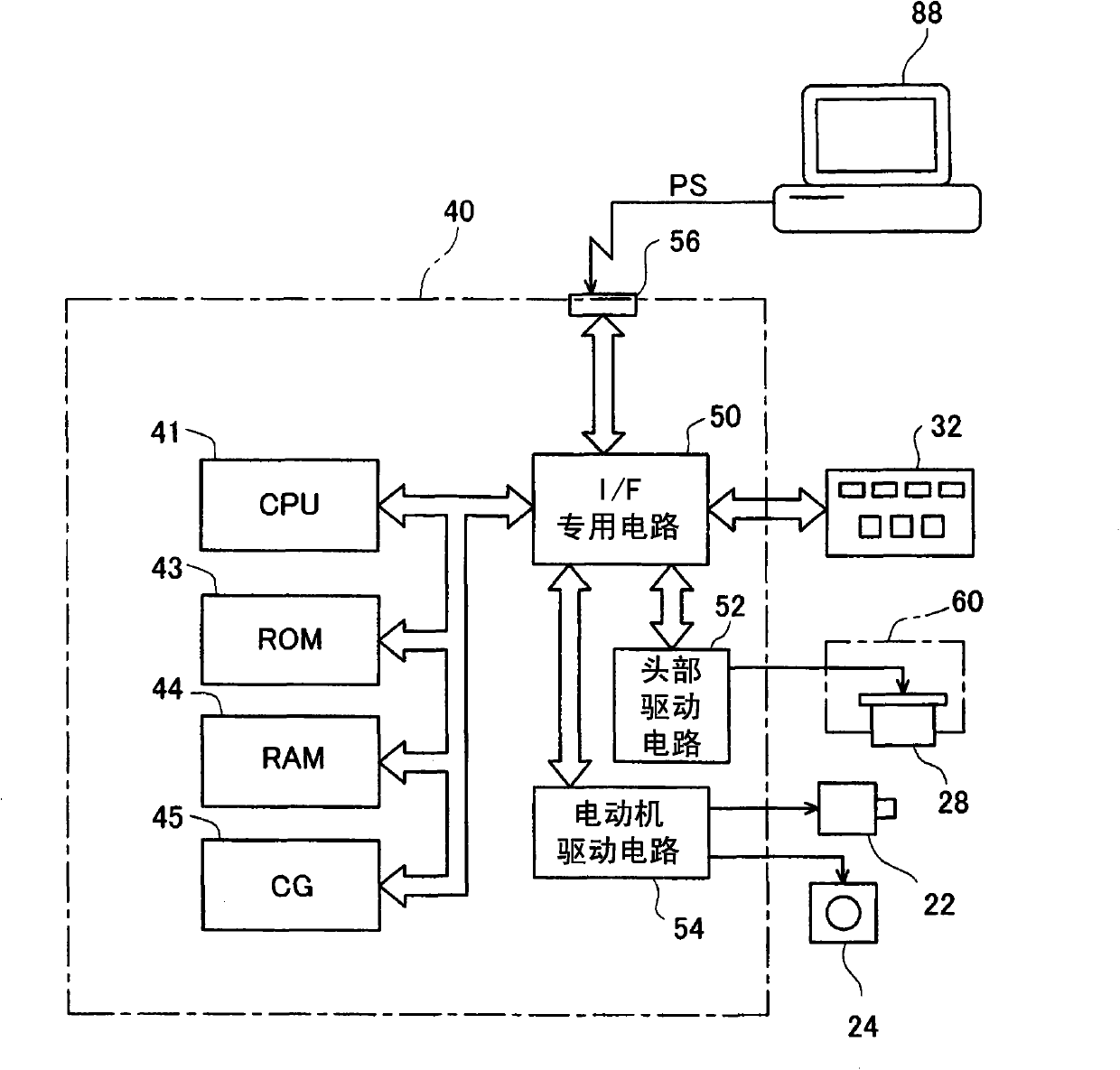

[0069] figure 1 It is a schematic configuration diagram of the printing system in the first embodiment of the present invention. The printing system of the first embodiment includes: an inkjet printer 20 ; and a computer 88 that supplies a print signal PS to the inkjet printer 20 . The inkjet printer 20 is connected to a computer 88 via a connector 56 .

[0070] The inkjet printer 20 is provided with: a moving mechanism that performs main scanning in which the carriage 30 reciprocates in a direction parallel to the axis of the platen 26; ) that conveys the paper P as a printing medium; the print head unit 60 mounted on the carriage 30 ; and the control circuit 40 that controls each part of the inkjet printer 20 .

[0071] The transport mechanism for transporting the paper P includes a paper feed motor 22 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com