Processing technologies of PE (polyethylene) coated paper and release paper

A processing technology and technology of coated paper, applied in the direction of paper, etc., can solve the problems of expensive extrusion machine, large amount of polyolefin consumption, high cost, etc., and achieve the effect of saving equipment cost investment, energy saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

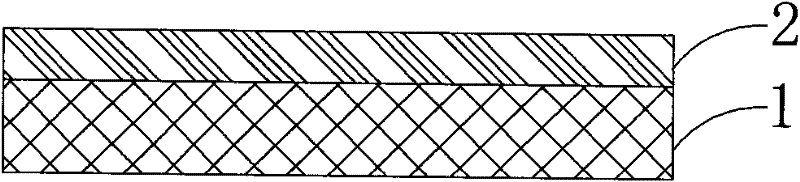

[0024] Embodiment: A kind of processing technology of single-sided coated paper mainly comprises the following steps: directly coat polyolefin emulsion on one surface of base paper 1 with a coater, then dry the base paper coated with polyolefin emulsion After drying, a polyolefin film 2 is formed on one surface of the base paper to obtain a single-sided coated paper.

[0025] The quality of the polyolefin film on the surface of the coated paper is 0.1g / m 2 ~20g / m 2 .

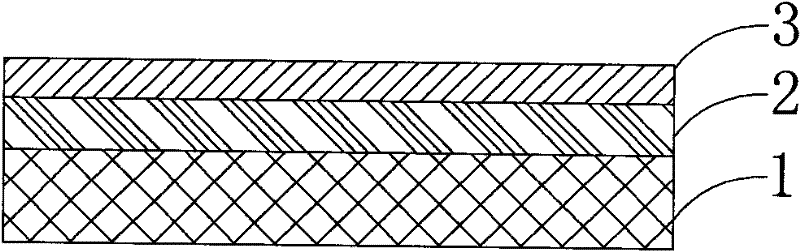

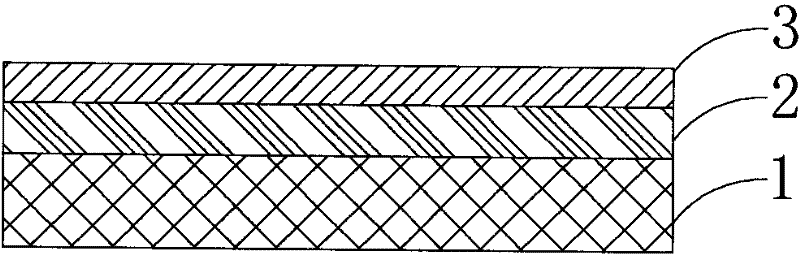

[0026] A processing technology for single-sided release paper, mainly comprising the following steps:

[0027] ①. Use a coating machine to directly coat polyolefin emulsion on one surface of base paper 1, then dry the base paper coated with polyolefin emulsion, and form polyolefin film 2 on one surface of the base paper after drying to obtain a single-sided coating membrane paper;

[0028] 2. Use a coating machine to coat a release agent on the surface of the polyolefin film of the single-sided coated paper,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap