Imaging equipment with upper photosensitive drum

A technology of imaging equipment and photosensitive drum, which is applied to the equipment, optics, and electric recording technology of applying charge pattern, etc., can solve the problems of wear, increase the contact pressure between the photosensitive drum and the developing roller, etc. Achieve the effect of increasing service life and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

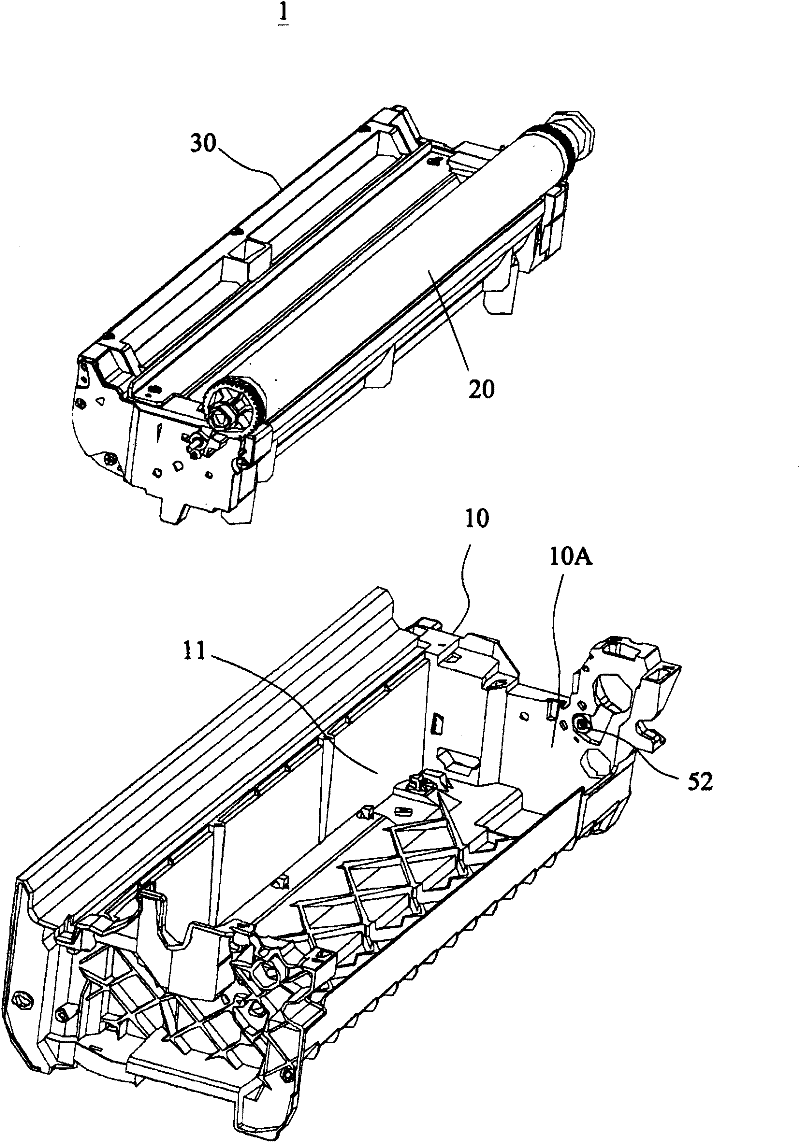

[0032] figure 1 An exploded perspective view of an imaging device 1 according to a preferred embodiment of the present invention is shown. Such as figure 1 As shown, the imaging device 1 of this embodiment includes a base 10 , a photosensitive drum 20 and a developing assembly 30 . The photosensitive drum 20 is mounted on a developing assembly 30 . The imaging component 30 is accommodated in the accommodating groove 11 of the base 10 . The roller 52 is rotatably mounted on a sidewall of the receiving groove 11 of the base 10 .

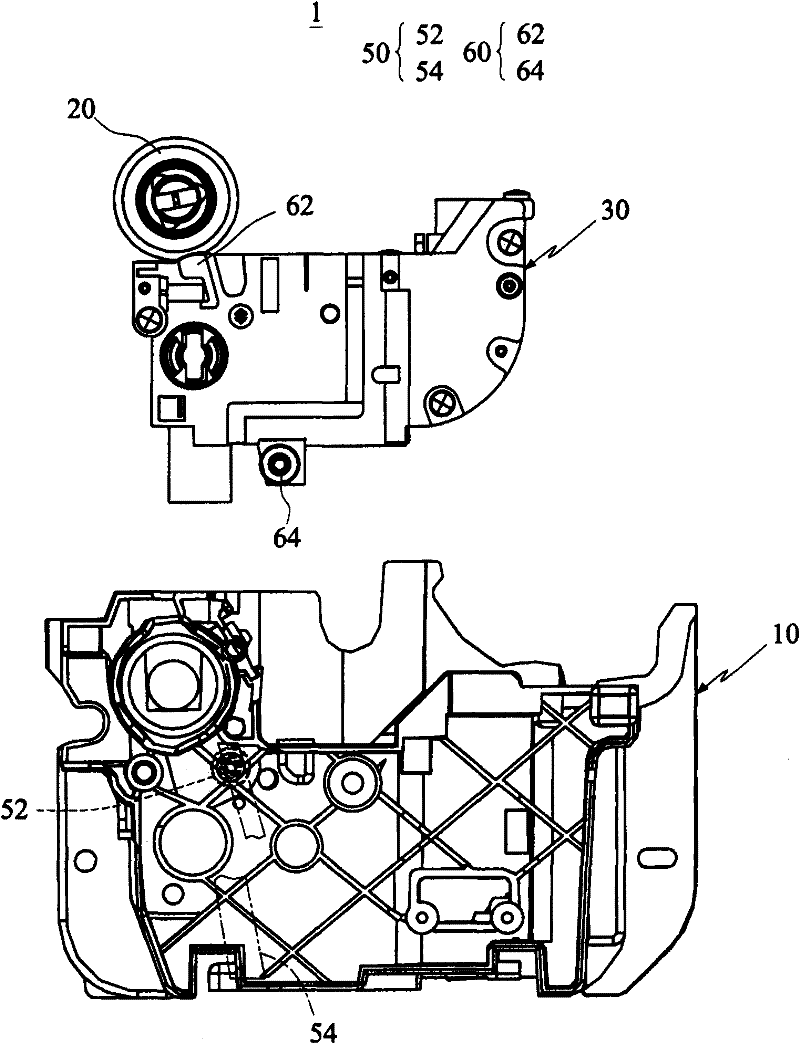

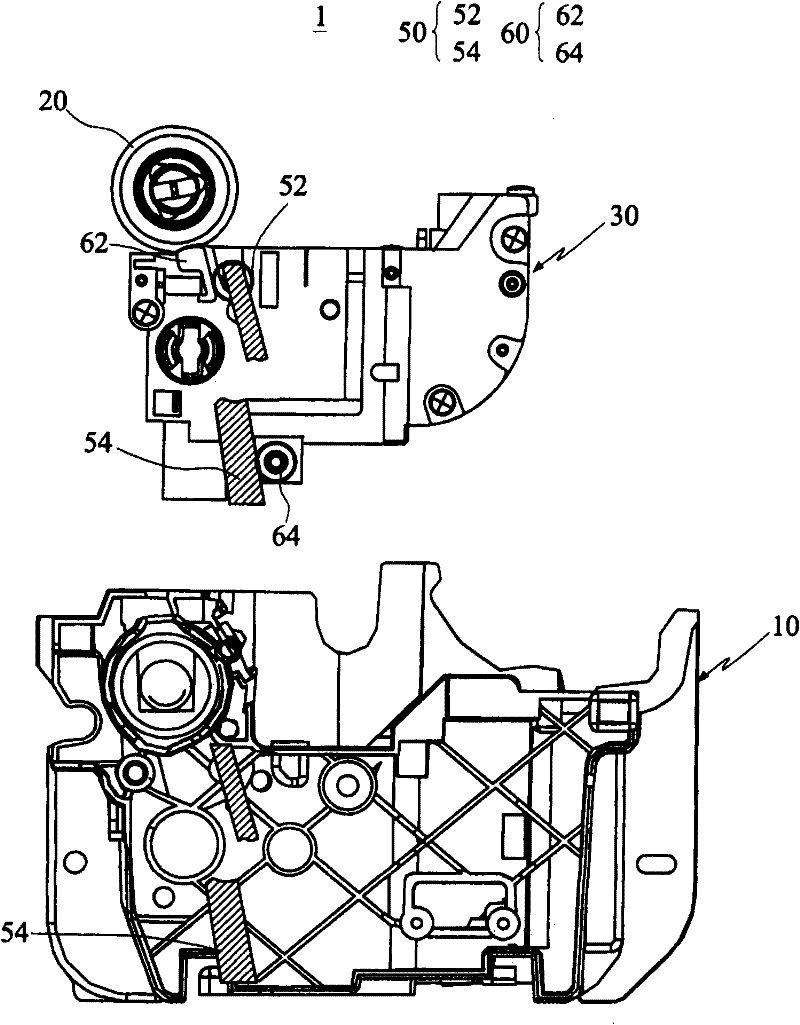

[0033] figure 2 An exploded side view of an imaging device 1 according to a preferred embodiment of the present invention is shown. Such as figure 2 As shown, the roller 52 is blocked by the base 10 and shown in dashed lines. In order to prevent the base 10 from blocking the mechanism features of the imaging assembly 30, the unnecessary part of the base 10 is cut off below, leaving only the part corresponding to the supporting assembly group 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com