Processed cheese and its preparation method

A technology for processing cheese and natural cheese, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as the elastic Q-sensing state that has not yet appeared, and achieve the effects of improving strong and stimulating flavor, easy realization, and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

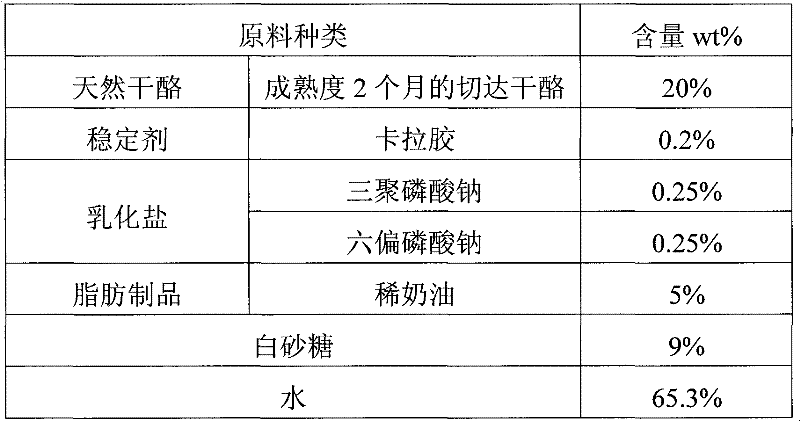

[0043] Raw material formula:

[0044]

[0045] The preparation method comprises the following steps:

[0046] Mix stabilizer, cream, white sugar and water accounting for 40% of the total mass of water in a water powder mixer at 70°C, and then mix the resulting mixture with natural cheese, emulsifying salt and the remaining water in a melting pot Emulsification, wherein the emulsification conditions are heating to 80°C, shear rate of 1800rpm, and time of 4min; after that, homogenization and sterilization can be carried out; among them, the homogenization pressure is 100bar, the temperature is 85°C; the sterilization is pasteurization: 85°C condition Sterilize for 15 minutes; after sterilization, hot-fill at 80°C, cool to 2°C to 8°C, and store.

[0047] Processed cheese prepared in this example: 25.2% solids; 9.23% fat; 4.70% protein; pH 6.0, and the percentages are the percentages of each component in the total mass of processed cheese.

Embodiment 2

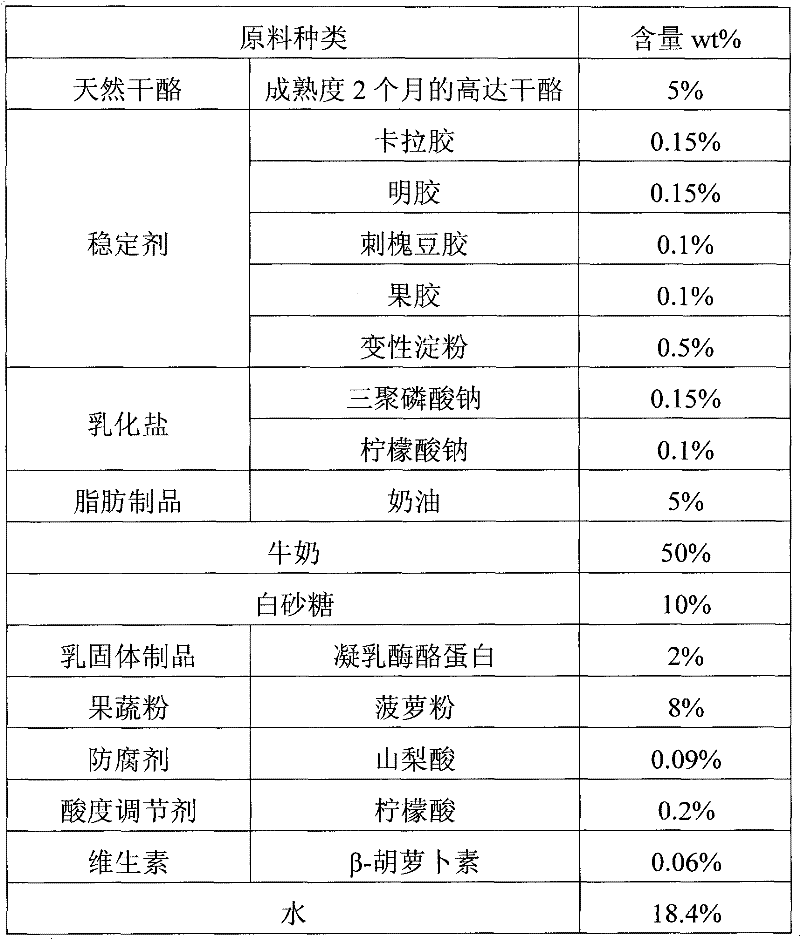

[0049] Raw material formula:

[0050]

[0051] The preparation method comprises the following steps:

[0052] Mix stabilizer, milk, white sugar and water accounting for 30% of the total water mass in a water powder mixer at 75°C, and then mix the obtained mixture with natural cheese, cream, emulsified salt, fruit and vegetable powder, preservatives, acidity The regulator, vitamins and water are mixed and emulsified in the melting pot, and the emulsification conditions are heating to 85°C, the shear speed is 3000rpm, and the time is 2min; after that, homogenization and sterilization can be carried out; among them, the homogenization pressure is 200bar, the temperature is 80 ℃; sterilization is pasteurization: at 85℃, sterilize for 12 minutes; after sterilization, hot fill at 80℃, cool to 2℃~8℃, and put it into the warehouse.

[0053] Processed cheese prepared in this example: solids 32.8%; fat 7.01%; protein 4.19%; pH 5.4, the percentages are the percentages of each compone...

Embodiment 3

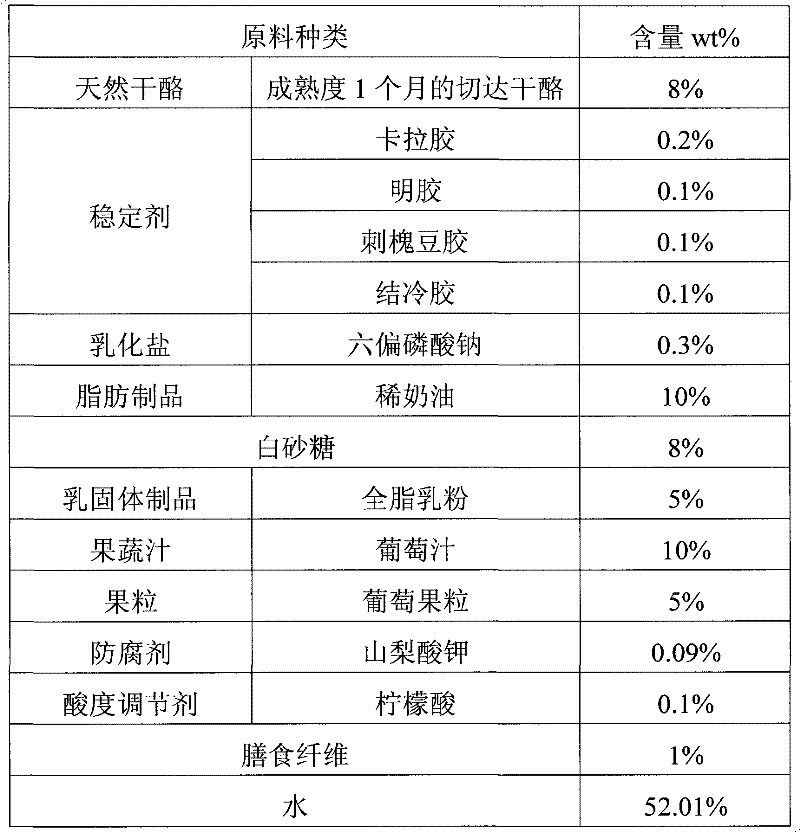

[0055] Raw material formula:

[0056]

[0057] The preparation method comprises the following steps:

[0058] Mix stabilizer, cream, white sugar and 60% of the total water mass in a water powder mixer at 80°C, and then mix the resulting mixture with natural cheese, emulsified salt, milk solid products, fruit and vegetable juices, and preservatives , acidity regulator, dietary fiber and the remaining water are mixed and emulsified in the melting pot, and the emulsification conditions are heating to 90°C, the shear speed is 900rpm, and the time is 5min; after that, homogenization and sterilization can be carried out; among them, homogenization Pressure 50bar, temperature 70°C; sterilization is pasteurization: sterilize at 80°C for 10 minutes; after sterilization, hot fill at 82°C, add fruit at the same time, cool to 2°C to 8°C, and put it into the warehouse.

[0059] Processed cheese prepared in this example: solids 30.21%; fat 7.94%; protein 3.25%, pH 5.4, and the percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com