Waste oil filter cone vacuum filter method

A filtration method and bucket-type technology, applied in the direction of filtration separation, separation method, gravity filter, etc., can solve the problems of poor cleanliness of the filtered oil, inability to decolorize the filtered oil, easy oxidation of the filtered oil, etc., and achieve a low temperature of the filtered oil. , easy maintenance, high cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

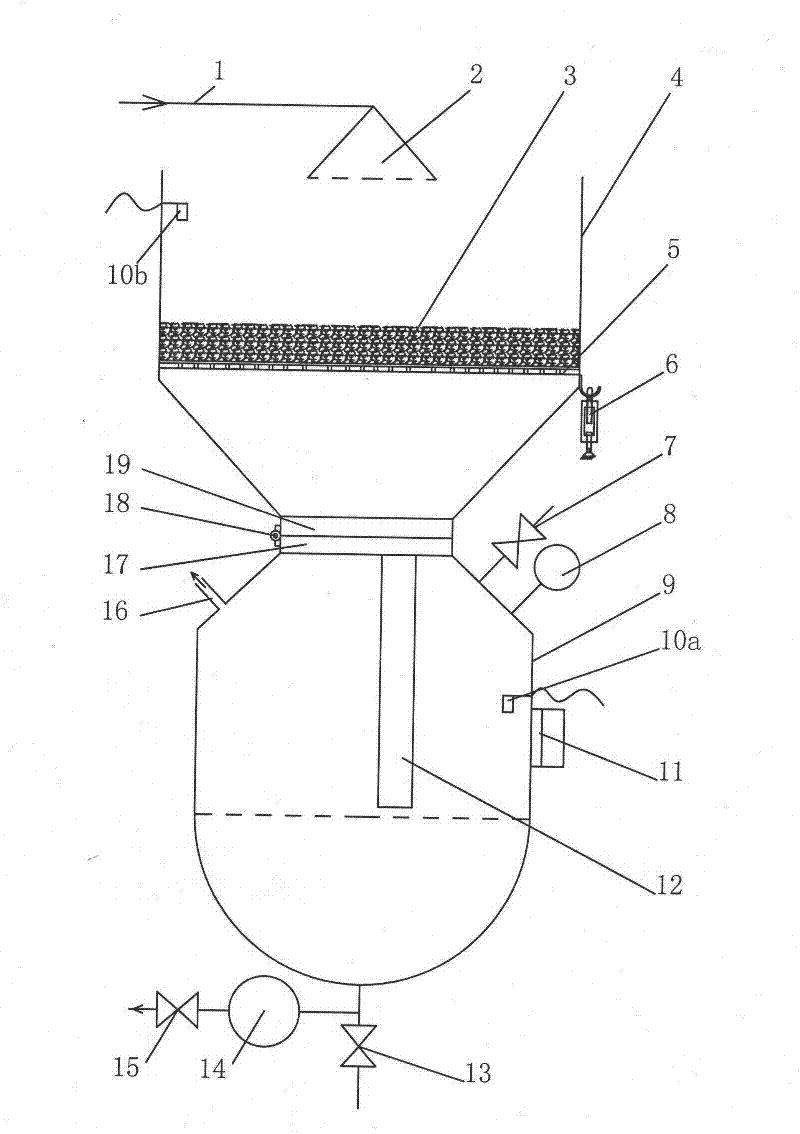

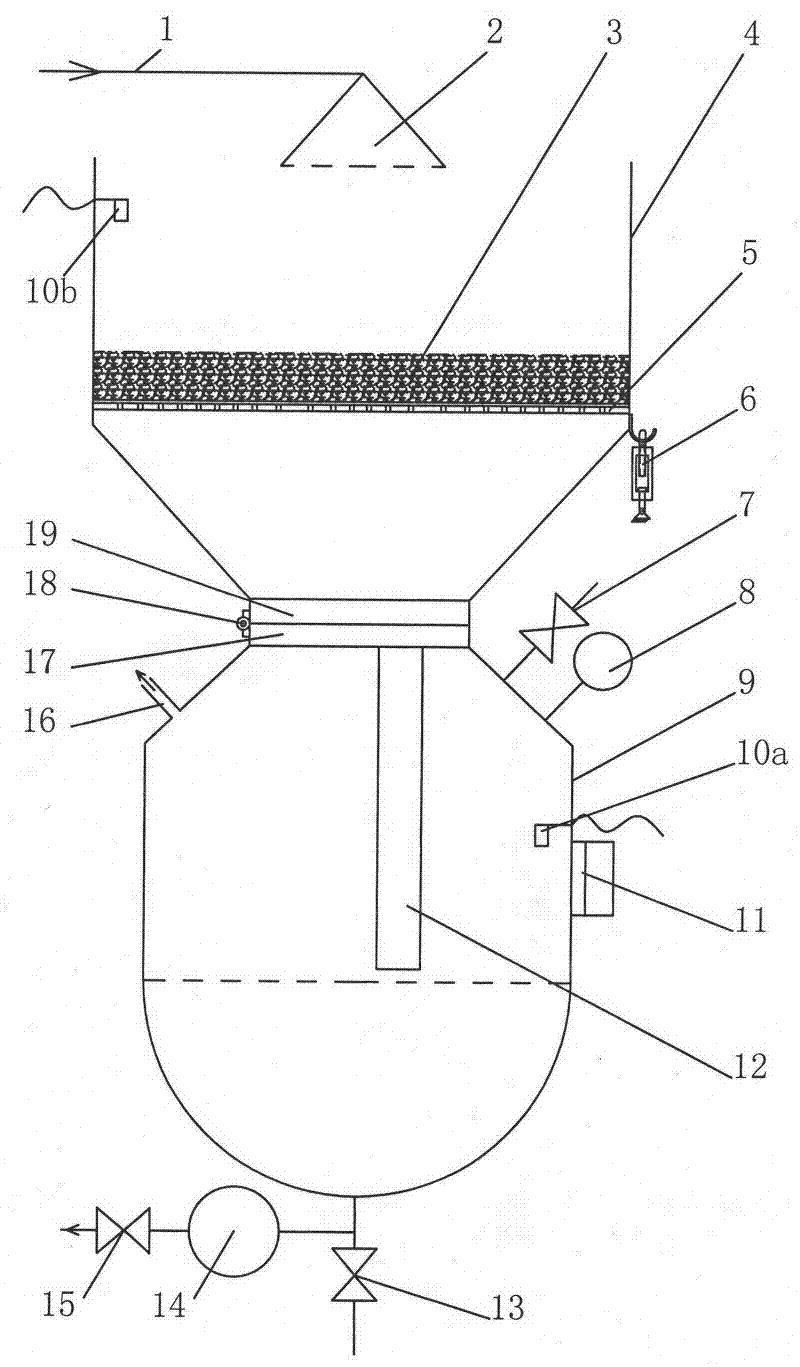

[0014] With reference to the accompanying drawings, a waste oil filter bucket type vacuum filtration method is characterized in that: the upper mouth of the vacuum tank 9 is connected with the lower mouth of the filter bucket 4, and the upper mouth of the filter bucket 4 is provided with a waste oil spray head 2. A filter plate 5 is arranged in the bucket 4, and a filter medium 3 is arranged on the filter plate 5; the filter medium 3 is kaolin, diatomaceous earth, clay, activated carbon or pure silica gel powder; The top is normal pressure, and the bottom of the filter plate 5 is negative pressure; the filter medium 3 is a mixture of one or more of kaolin, diatomaceous earth, clay, activated carbon or pure silica gel powder, and the mesh number of the filter medium is 10. -300 mesh; the oil temperature of the waste oil is controlled at 0°C-150°C; the negative pressure of the vacuum tank 9 is 0.001-0.1Mpa; an oil leakage pipe 12 is arranged in the vacuum tank 9, and the oil leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com