High-precision eccentricity-adjustable eccentric shaft

A technology of eccentric shaft and eccentric distance, which is applied in the direction of eccentric shaft, can solve the problems of poor combination accuracy of eccentric sleeve and eccentric shaft, reduce the service life of parts, and easily cause large noise, so as to achieve low noise, long service life, The effect that is not easy to impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

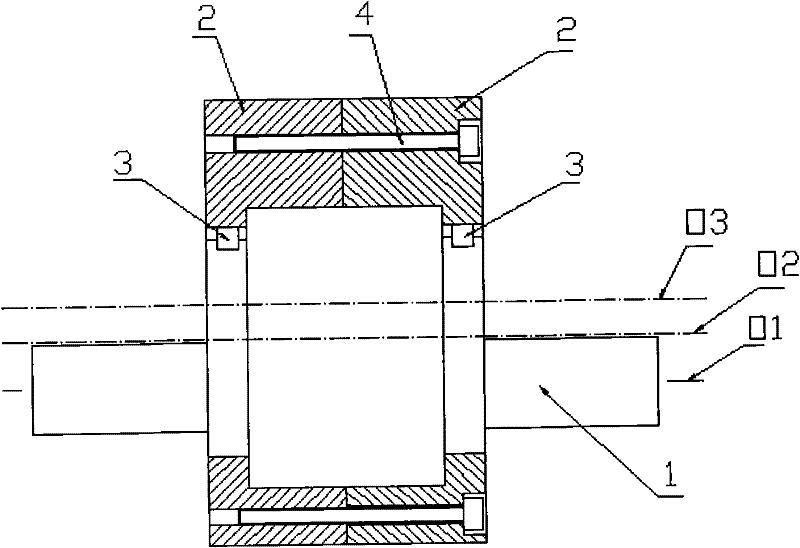

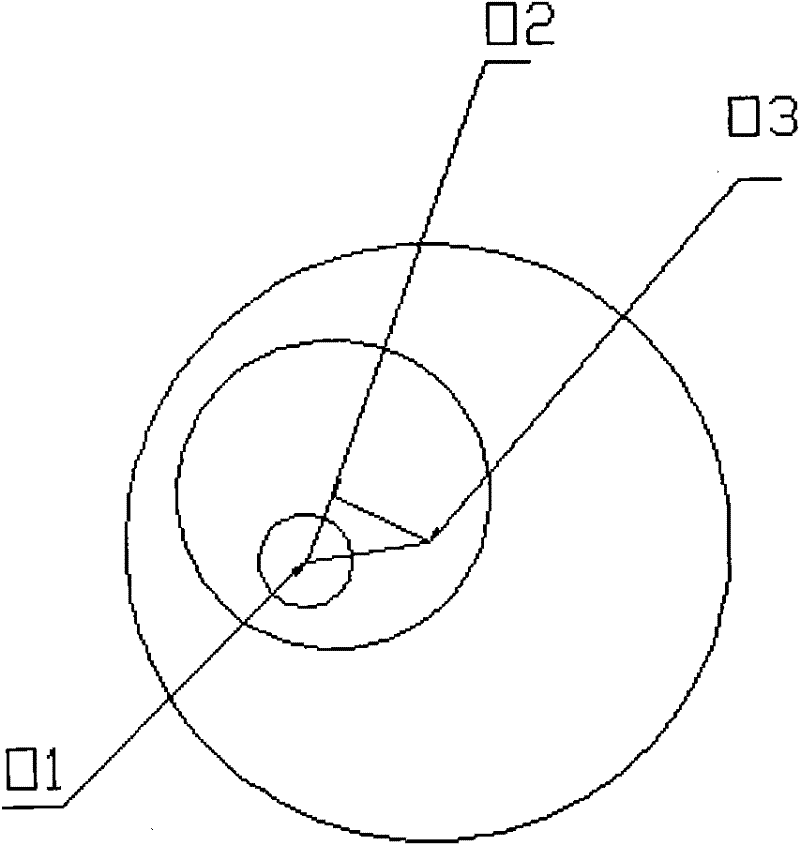

[0010] Install the two keys (3) in the key grooves at both ends of the eccentric shaft respectively, and install the two eccentric sleeves (2) symmetrically from both ends of the eccentric shaft (1) in the middle of the eccentric shaft (1), and use the bolts (4) Fasten the left and right eccentric sleeves (2) together; if it is necessary to adjust the eccentric distance, loosen the bolts (4) so that the left and right eccentric sleeves (2) are separated from the key (3), and the left and right eccentric sleeves ( 2) At the same time, rotate the same angle relative to the eccentric shaft. Since the size of the eccentric distance O1-O3 is related to the size of the included angles O1, O2, and O3, it can be realized only by adjusting the sizes of the included angles O1, O2, and O3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com