Concrete bridge bottom crack detecting device

A technology for detecting devices and cracks, which is applied in the direction of measuring devices, optical devices, instruments, etc., which can solve the problems of affecting work efficiency, fatigue of testing personnel, and high cost of personnel, so as to improve the engineering environment, intuitive detection results, and reduce rental costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

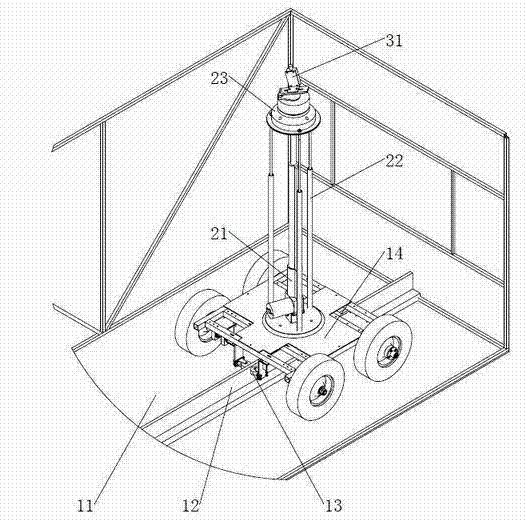

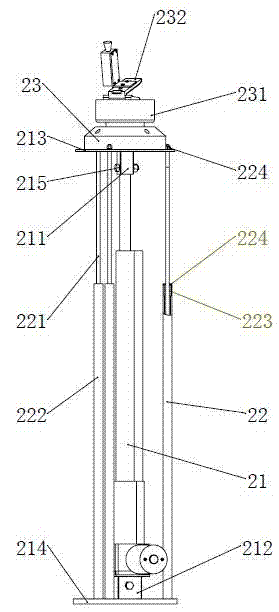

[0025] The bridge bottom surface crack detection device of the present invention mainly includes three modules: a traveling chassis, a camera orientation and attitude adjustment module, and a crack detection module. figure 1 It is a schematic diagram of the overall structure of a specific embodiment of the present invention, combined below figure 1 ~5 introduces it in detail.

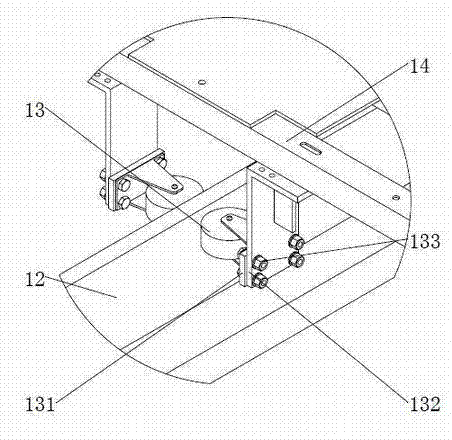

[0026] Such as figure 1 , 2 , the truss arm 11 of the bridge inspection vehicle extends below the bridge and is the motion platform of the entire crack inspection device. 12 is the lightweight guide rail installed on the truss arm 11, and the connection mode is a screw connection. The material of the lightweight guide rail can be wood or engineering plastics, and the length is the same as that of the truss arm 11 . 13 is the elastic guide wheel installed on the four-wheel chassis 14. There are two elastic guide wheels 13, which are symmetrically installed on both sides of the lightweight guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com