Multi-step positioning clamp for contactor

A technology for positioning fixtures and contactors, used in instruments, measuring instrument components, measuring devices, etc., can solve problems such as inability to meet the needs of testing, and achieve the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

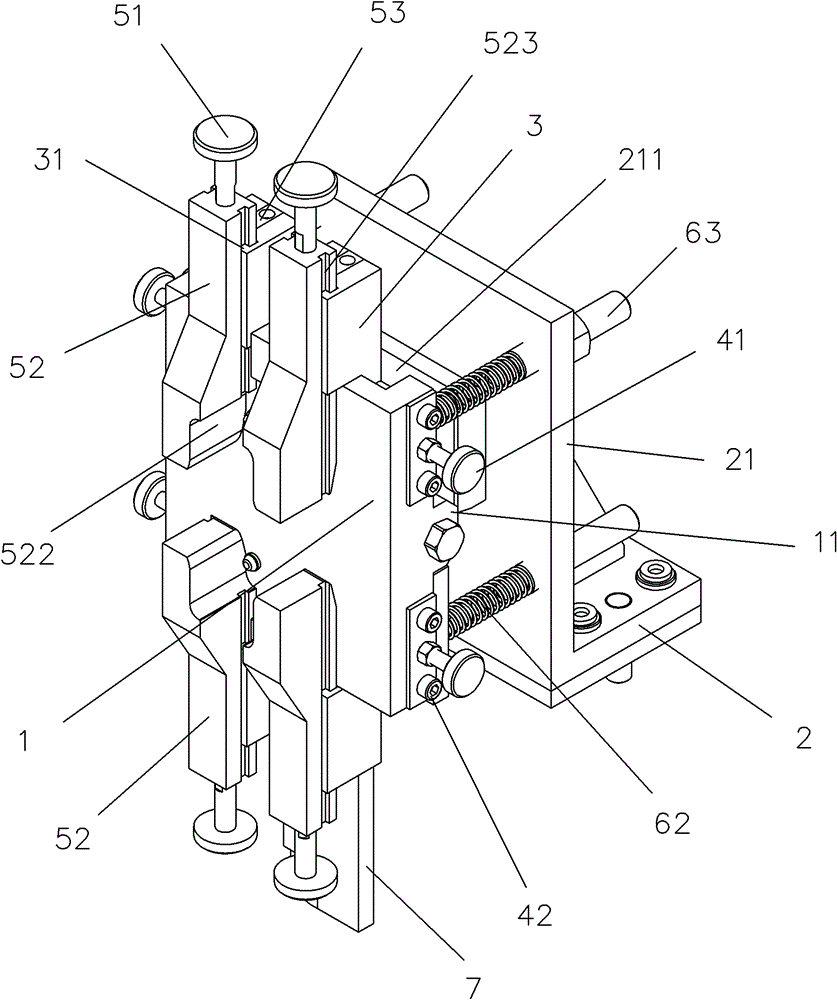

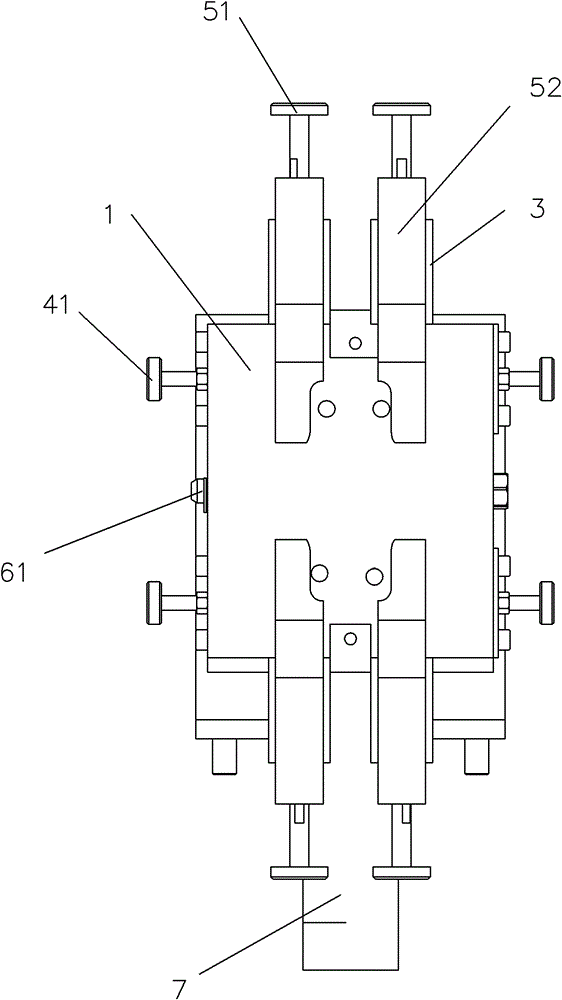

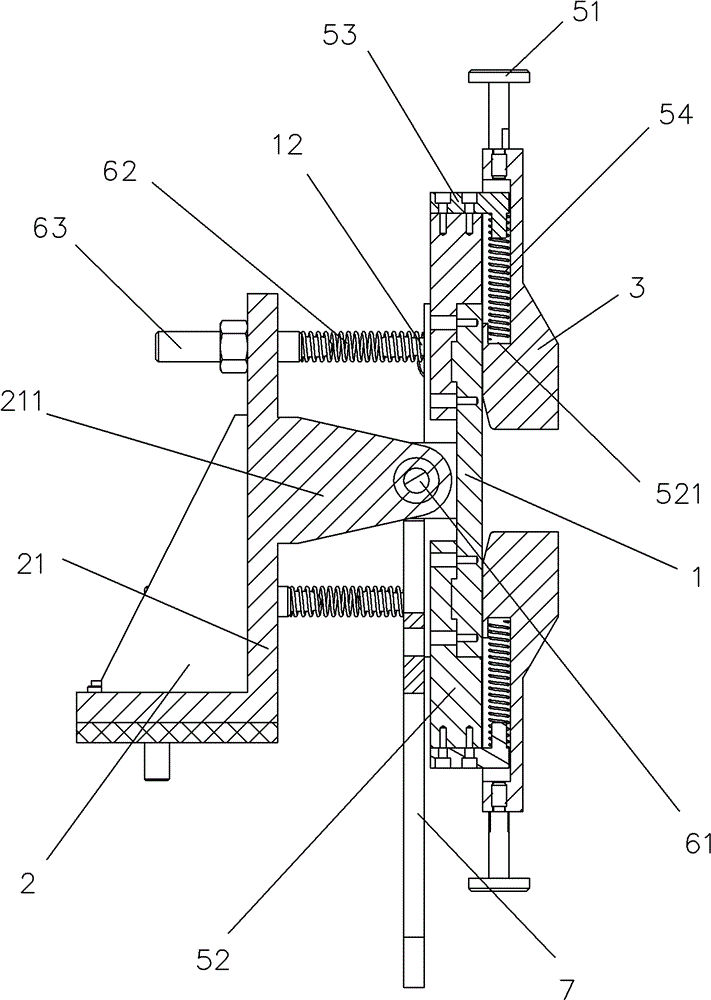

[0033] Embodiment, referring to the accompanying drawings, a multi-position positioning fixture for a contactor according to the present invention includes a contactor positioning plate 1 for placing the contactor, and a fixture support 2 for fixing to the machine equipment , a swing mechanism and four elastic jaw mechanisms; the contactor positioning plate 1 is vertically arranged; the contactor positioning plate 1 is connected with the fixture support 2 through the swing mechanism, so that the contactor positioning plate 1 can swing back and forth and tilt ; The four elastic jaw mechanisms are divided into two groups, which are respectively installed on the upper and lower parts of the contactor positioning plate 1, so as to clamp the contactor 10 from the four corners of the contactor 10 placed on the contactor positioning plate.

[0034] Further, it also includes four jaw positioning seats 3, and the four jaw positioning seats 3 are divided into two groups, which are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com