Device and method for assembling spring in correction fluid pen point

A technology of an assembling device and an assembling method, which is applied in the directions of hand-held tools, manufacturing tools, etc., can solve the problems of spring loading deviation, affecting the assembly yield and efficiency of the correction liquid pen, reducing the spring installation yield and efficiency, etc., so as to improve the assembly efficiency, improve assembly quality and reliability, and reduce defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

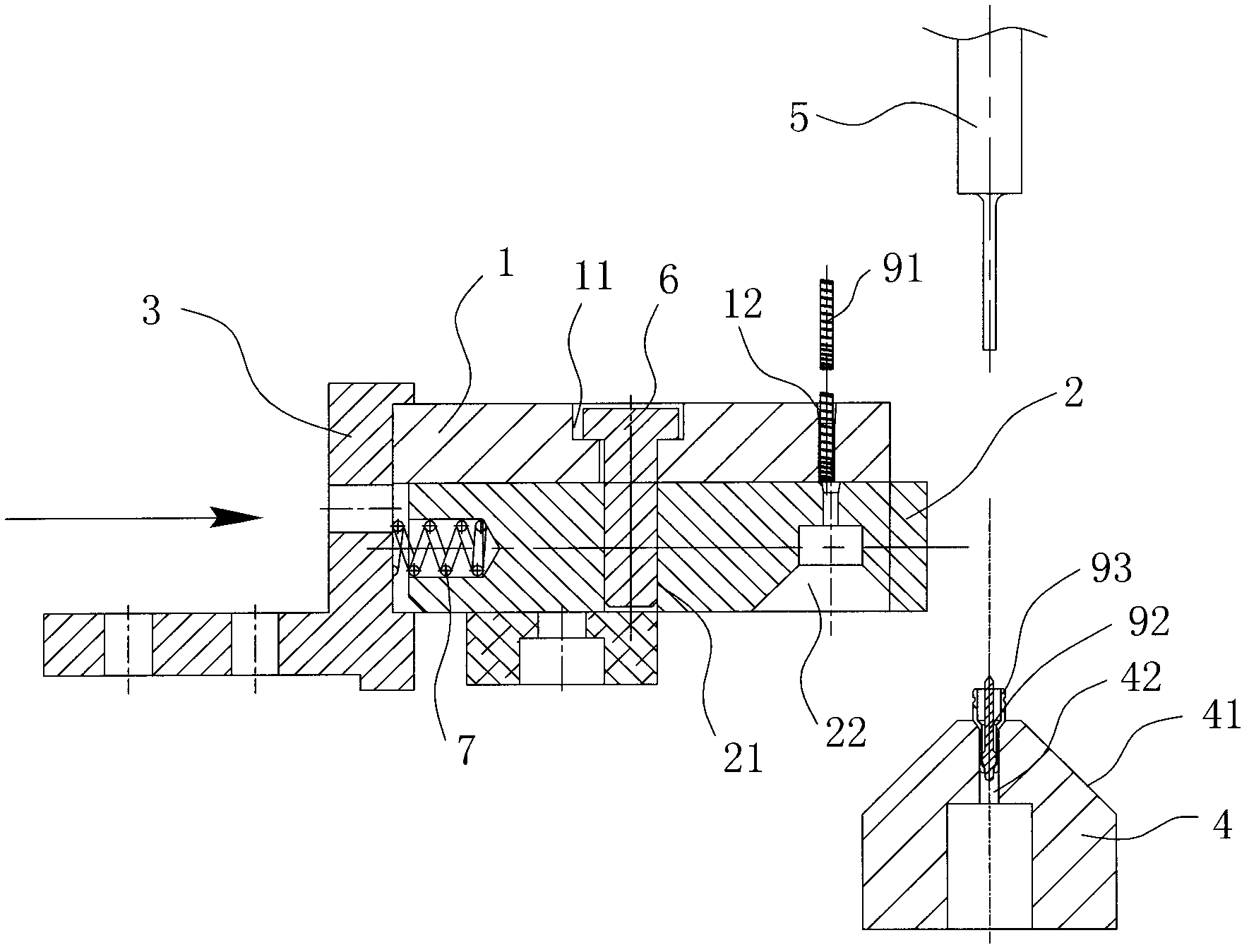

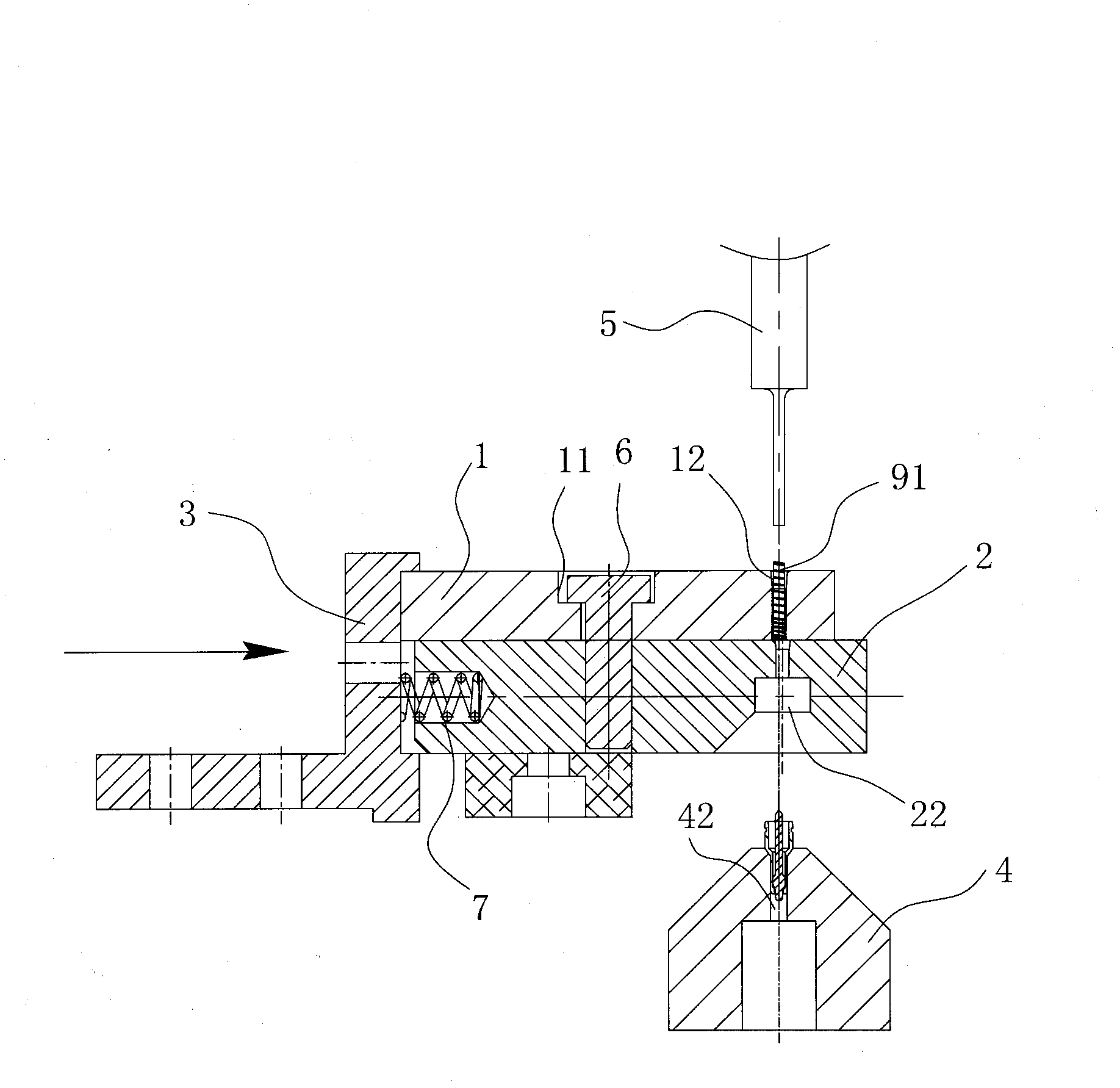

[0028] The technical solutions in the preferred embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

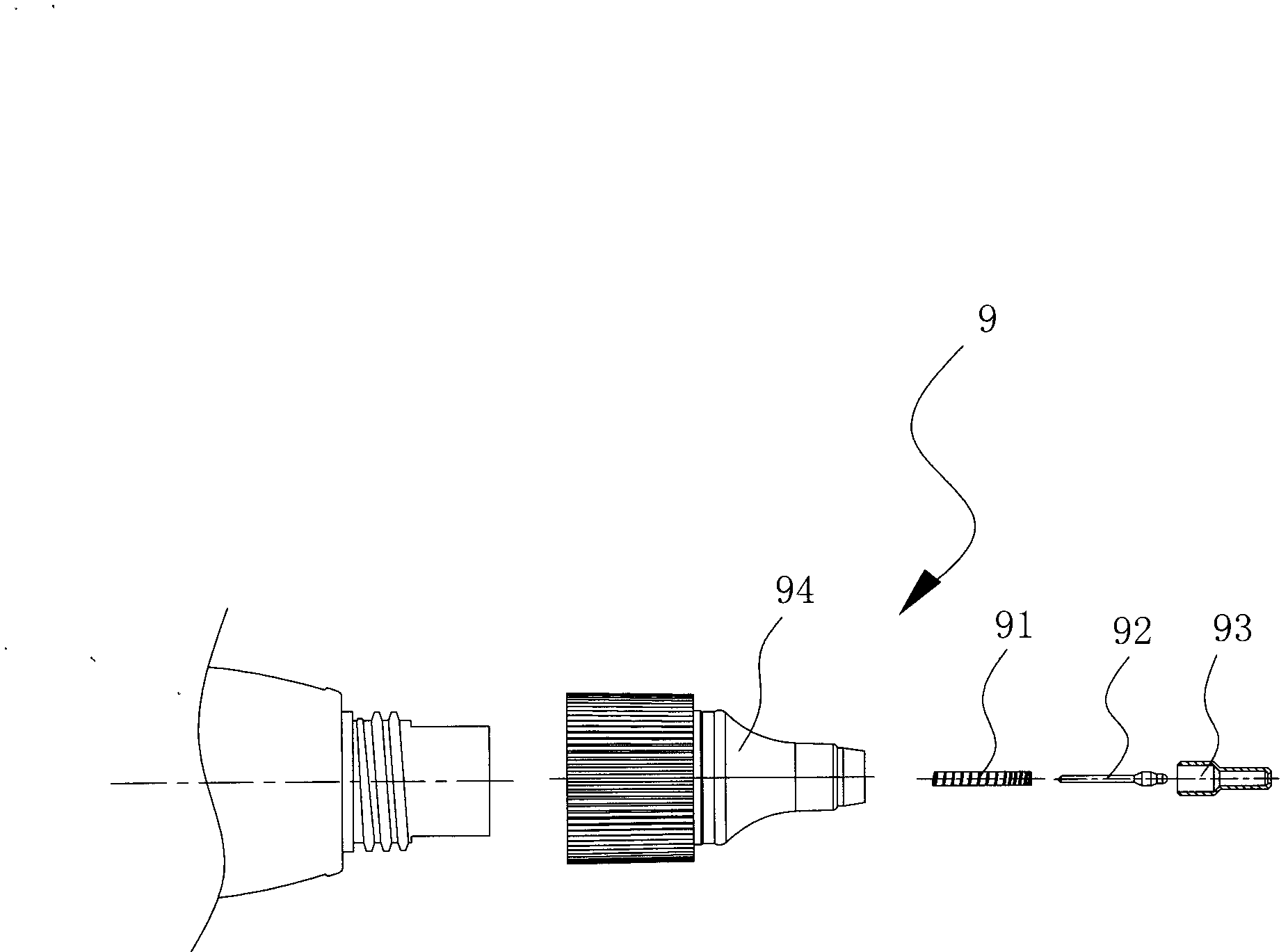

[0029] Such as figure 2 As shown, the assembly device of the inner spring of the correction fluid pen tip disclosed by the present invention is a part of the automatic assembly equipment of the correction fluid pen, and it is suitable for automatic assembly such as figure 1 The pen tip 9 of the correction fluid pen shown is to put the spring 91 in the correction fluid pen tip into the outer periphery of the needle rod 92 in the limit sleeve 93 .

[0030] The assembly device includes an upper slider 1, a lower slider 2, a pusher 3 for pushing the upper slider and the lower slider to slide, a material holder 4 for accommodating a limit sleeve 93, and a push spring 91 entering the bearing. The ejector rod member 5 in the upper limit sleeve 93 of the material seat 4 . Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com