Main jib structure for fork installing machine

A technology for forklifts and main arms, applied in the direction of lifting devices, etc., can solve the problems of poor uniformity of force on the boom, difficult to release welding stress, and short use time of the main arm, so as to improve the stability and lifting performance, Reduce welding stress and welding process difficulty, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

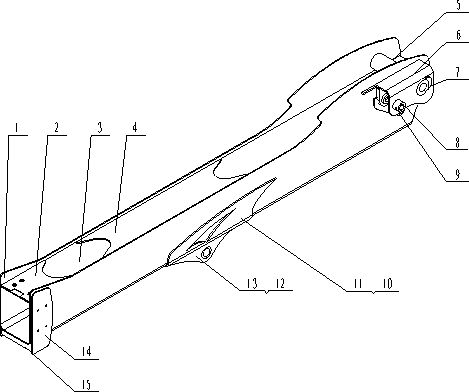

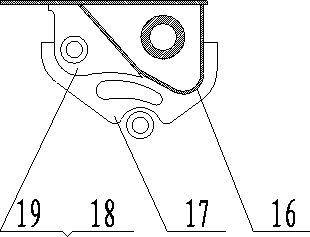

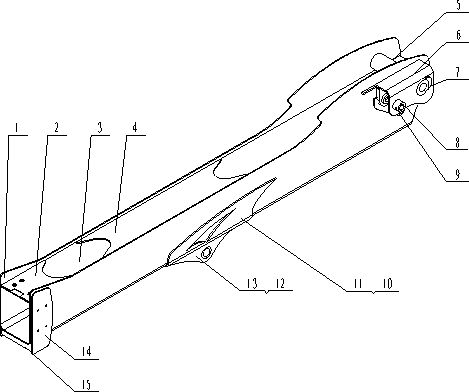

[0010] Embodiment 1: The main arm includes: U-shaped main arm plate 1, front upper web 2, upper cover plate 3, upper web 4, main shaft sleeve 5, bending cover plate 6, crescent plate 7, first shaft sleeve 8. The second shaft sleeve 9, the left web 10, the right web 11, the oil cylinder support plate 12, the third shaft sleeve 13, the front side plate 14, the front lower rib plate 15, the rear inner curved plate 16, the rear side Web 17, rear inner web 18 and fourth bushing 19. The U-shaped main arm plate 1 is the main body, and the upper cover plate 3 is welded on the inner side of the U-shaped main arm plate 1 to form a high-strength box structure; the front upper web 2 and the upper web 4 are respectively welded on the front of the upper cover plate 3 and the middle position; the second bushing 9 is respectively welded on the two sides behind the wall plate of the U-shaped main arm plate 1; the bending cover plate 6 is welded on the rear side of the wall plate of the U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com