Titanium dioxide nanometer composite structure film and preparation method thereof

A nano-composite, titanium dioxide technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of difficult to accurately control the preparation process, high risk, complex process, etc., and achieve good dye adsorption performance and uniform distribution. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

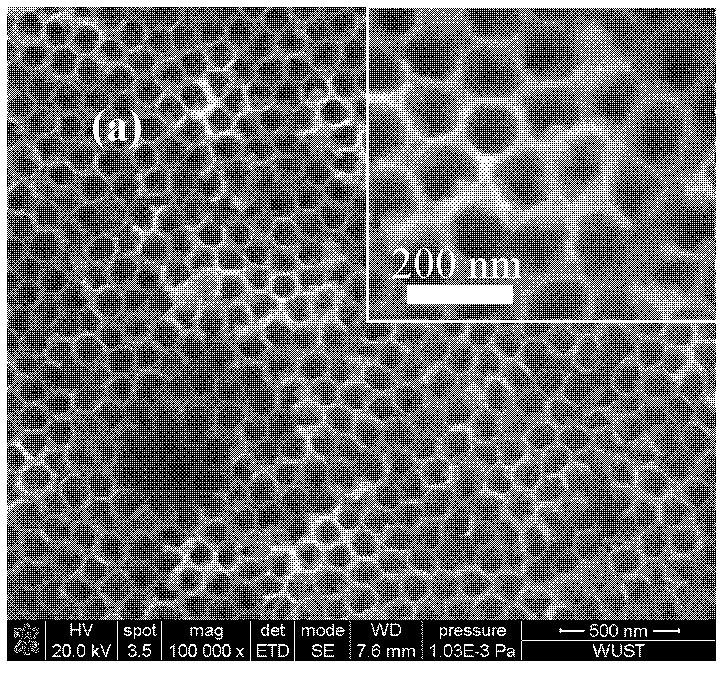

[0031] A titanium dioxide nanocomposite structure film and a preparation method thereof. Putting the polished and polished titanium-containing metal sheet with a titanium content of 90-99.99 wt% as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 40-60V, and the anodic oxidation time is 0.5-2 hours; Then the titanium-containing metal sheet after anodic oxidation is cleaned, dried, and then the dried titanium-containing metal sheet is placed in H 2 In O, under the condition of 80-150 DEG C, hydrothermally react in a closed container for 2-8 hours, cool naturally, and obtain a titanium dioxide nanocomposite structure film on the surface of the titanium-containing metal sheet.

[0032] The electrolyte in this embodiment is 0.05-0.5 wt% fluorine-containing ions, 0.5-5 wt% H 2 A mixed solution of O and 95-99wt% ethylene glycol; the fluorine-containing ion is NH 4 F.

Embodiment 2

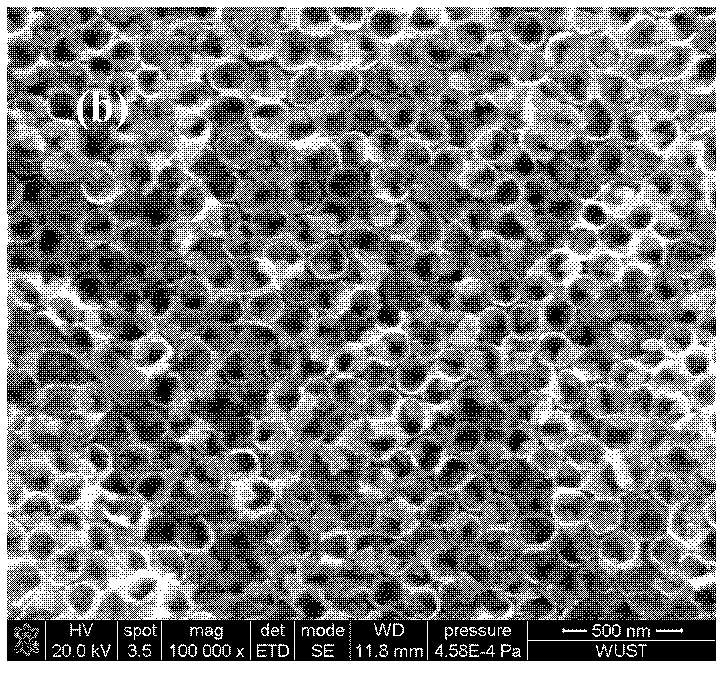

[0034] A titanium dioxide nanocomposite structure film and a preparation method thereof. Putting the polished and polished titanium-containing metal sheet with a titanium content of 90-99.99 wt% as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 40-60V, and the anodic oxidation time is 0.5-2 hours; Then the titanium-containing metal sheet after anodic oxidation is cleaned, dried, and then the dried titanium-containing metal sheet is placed in an H 2 In a mixed solution of O and 70-95 wt% alcoholic organic matter, hydrothermally react in a closed container at 200-300°C for 6-15 hours, and cool naturally to obtain a titanium dioxide nanocomposite structure film on the surface of a titanium-containing metal sheet.

[0035] In this embodiment: the electrolyte is 0.3-0.8wt% fluorine-containing ions, 2-15wt% H 2 A mixed solution of O and 85-95wt% ethylene glycol, the fluoride ion is NH 4 F; Alcoholic organic matter is ethanol.

Embodiment 3

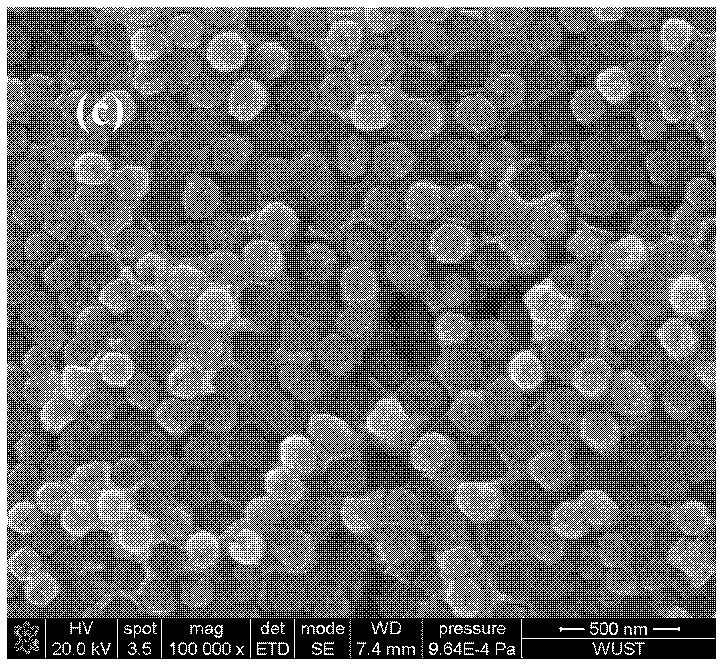

[0037] A titanium dioxide nanocomposite structure film and a preparation method thereof. Putting the polished and polished titanium-containing metal sheet with a titanium content of 90-99.99 wt% as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 40-60V, and the anodic oxidation time is 0.5-2 hours; Then the titanium-containing metal sheet after anodic oxidation is cleaned, dried, and then the dried titanium-containing metal sheet is placed in an H 2 In a mixed solution of O and 50-80 wt% alcoholic organic matter, hydrothermally react in a closed container at 150-250°C for 8-10 hours, cool naturally, and obtain a titanium dioxide nanocomposite structure film on the surface of a titanium-containing metal sheet.

[0038] In this embodiment: the electrolyte is 0.8-3wt% fluorine-containing ions, 5-20wt% H 2 A mixed solution of O and 77-85wt% ethylene glycol, the fluoride ion is NH 4 F; organic alcohols are methanol and ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com