Double-color non-woven fabric and making process thereof

A production process and non-woven fabric technology, applied in the field of two-color non-woven fabrics and its production, can solve the problem of single color, etc., achieve broad market application prospects, increase recognition ability and aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

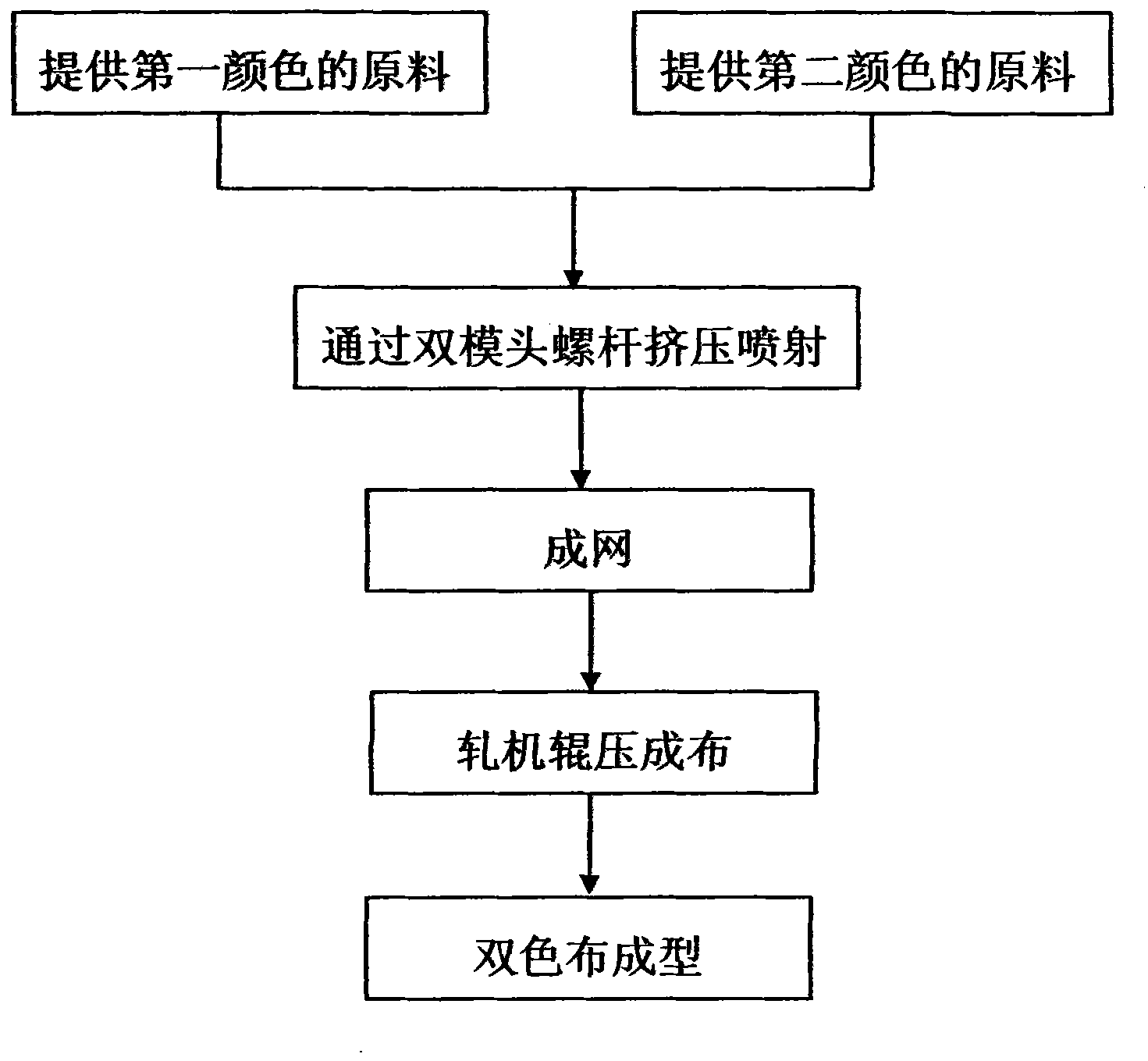

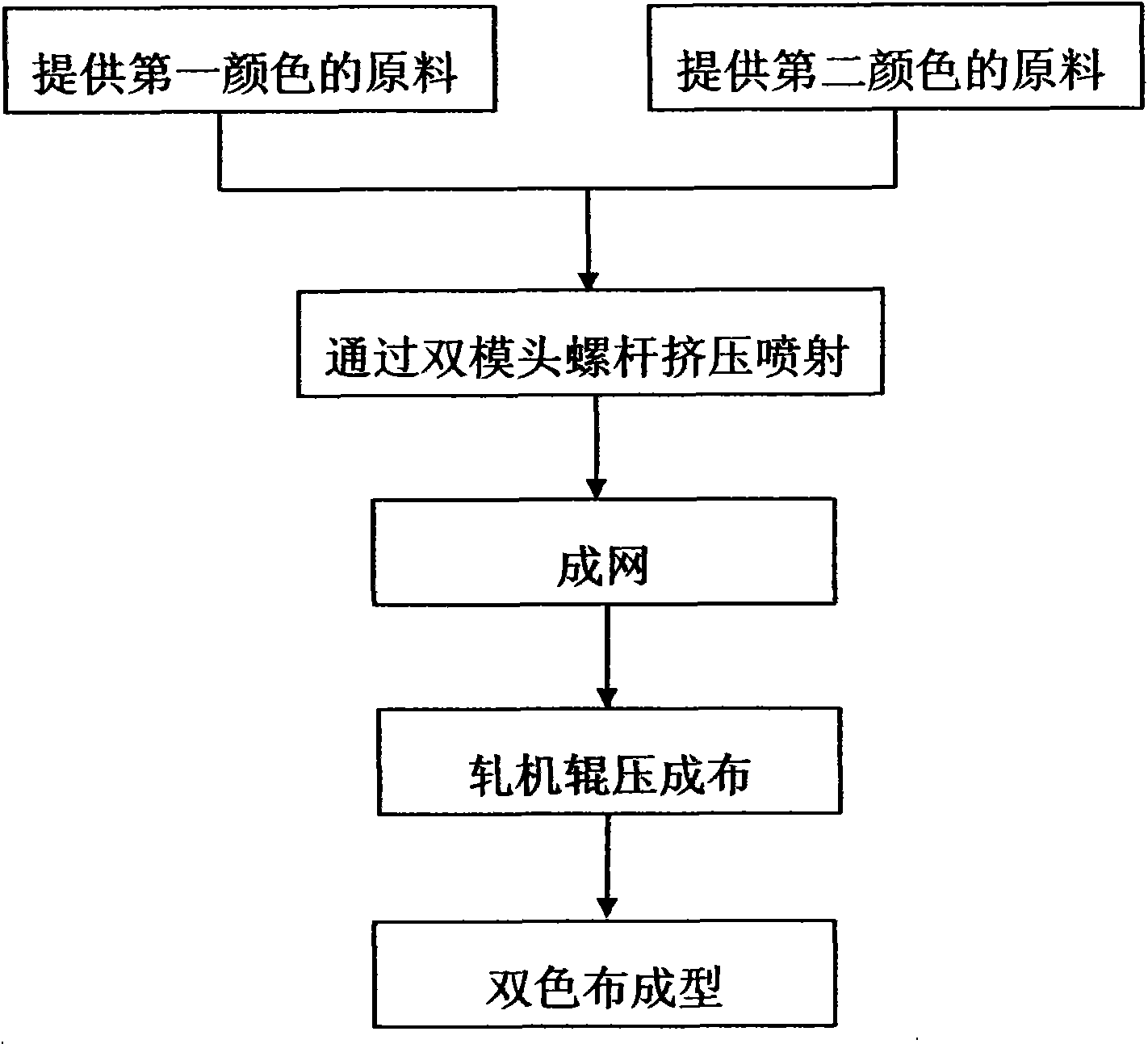

[0015] combine figure 1 The manufacturing process of the shown two-color nonwoven fabric of the present invention, the implementation mode of an embodiment of the present invention is as follows:

[0016] Prepare 10,000 grams of polypropylene raw materials, add different color masterbatches to the first and second troughs and mix them, then extrude and spray the raw materials through different screws to form a web, and then pass through the width of 24000-32000mm at a speed of 3m / min 1. The temperature is 110-120 ℃, and the patterned rolls of the rolling mill are rolled and pressed into a cloth, and finally formed. The two-color process is specifically to use two-color masterbatches to add 98% polypropylene to stir, pass through the first and second screws respectively, heat to 210 to 230 ° C to melt into a liquid state, and then enter the screw extrusion, spray The wire is formed into a web, and rolled into a cloth by rolling rolls together. Among them, in specific applicati...

specific Embodiment approach

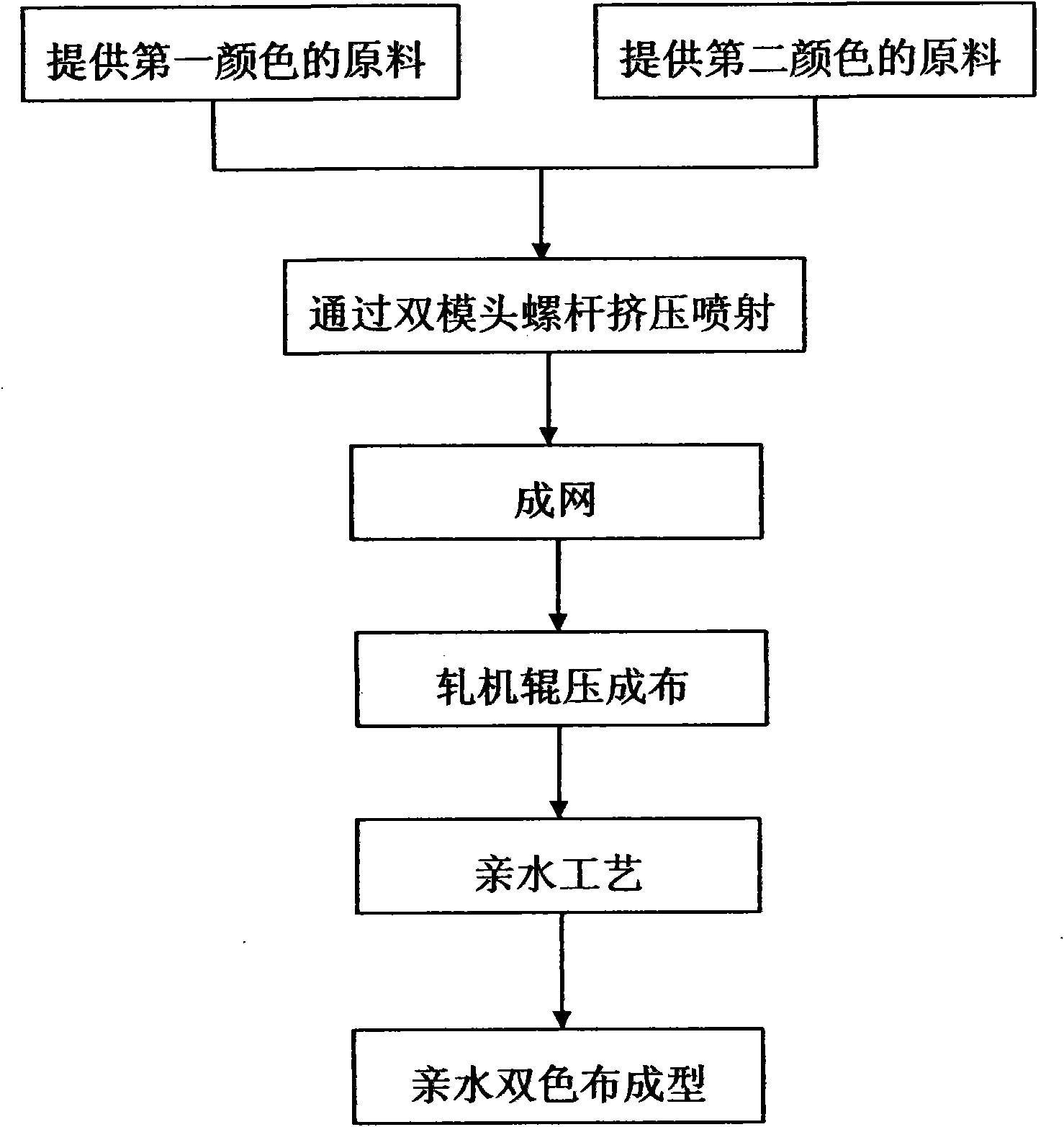

[0019] combine figure 2 The manufacturing process of the shown two-color non-woven fabric of the present invention, another embodiment of the present invention is as follows:

[0020] Prepare 10,000 grams of polypropylene raw materials, add different color masterbatches to the first and second troughs and mix them, then extrude and spray the raw materials through different screws to form a web, and then pass through the width of 24000-32000mm at a speed of 3m / min 1. The temperature is 110-120 ℃, and the patterned rollers of the rolling mill are rolled and rolled into a cloth, and then undergo a hydrophilic process, and finally formed. The hydrophilic process is to add 100 grams of hydrophilic agent to 20,000 grams of high-purity water, then coat (roller), and dry at a high speed to form a cloth. The hydrophilizing agent adopts php37 hydrophilizing agent produced by an American manufacturer, which is used after being diluted with high-purity water. Finally, a hydrophilic two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com