Novel light emitting diode (LED) lamp for photoelectric heat separation and manufacturing method thereof

A technology of LED lamps and LED lamp bodies, which is applied in the field of electro-optics, can solve the problems that affect the promotion and application of LED lighting lamps, high cost, harsh conditions, etc., and achieve the effects of facilitating promotion, prolonging service life, and facilitating installation, maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail with preferred embodiment:

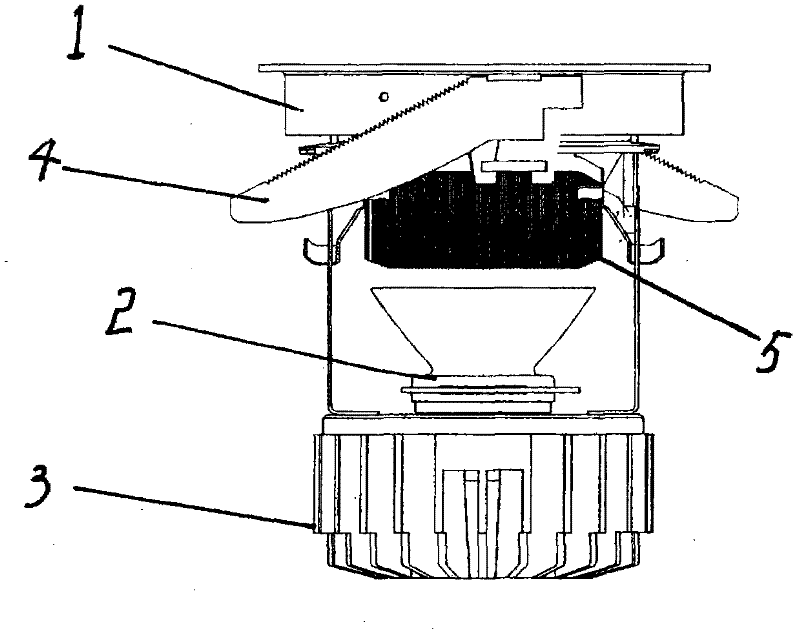

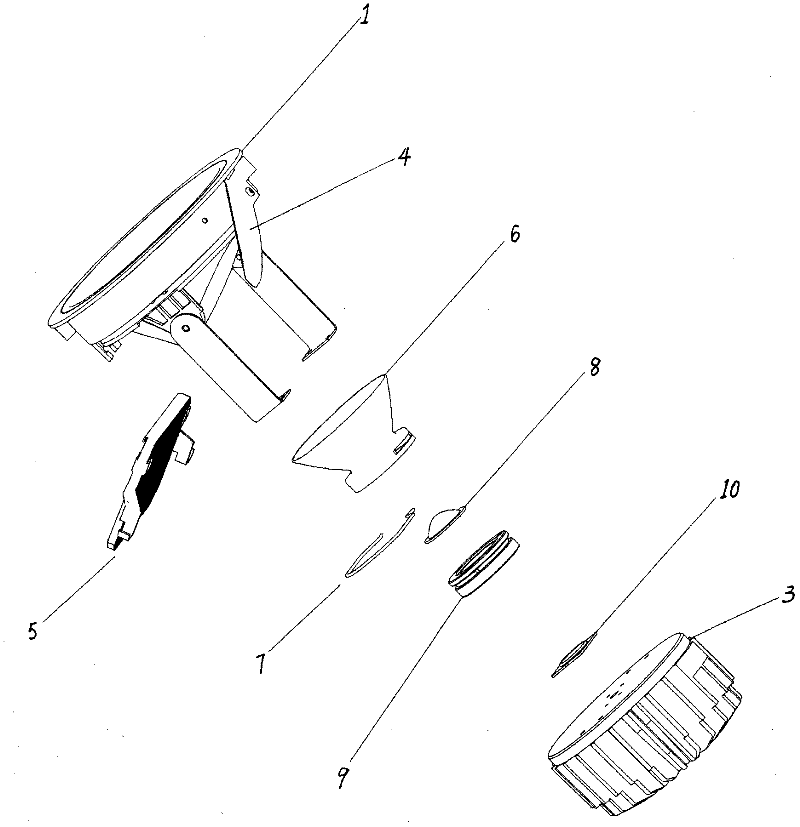

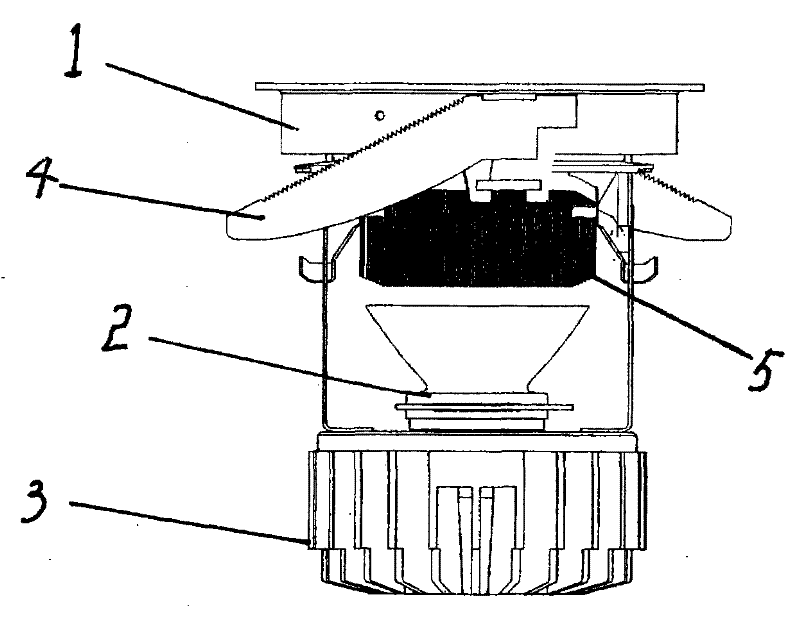

[0012] The invention consists of a mounting bracket (1), an LED lamp body (2) and a radiator (3). The periphery of the mounting bracket (1) can be provided with mounting shrapnel (4), and the middle cavity of the mounting bracket (1) can be provided with an optical grille (5); the LED lamp body (2) consists of an optical reflector (6), a reflector The installation frame (7), the secondary optical lens (8), the LED fixing piece (9) and the LED light source (10) are composed, and the LED light source (10) can be a high-power integrated LED light source; the radiator (3) is screwed or inserted connected to the bottom of the LED lamp body (2), and fixedly connected to the mounting bracket (1).

[0013] The present invention is powered by an external DV constant current drive circuit.

[0014] The implementation method of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com