Fixture for detecting symmetry degree of key slot of automobile engine crankshaft

A technology of automobile engine and crankshaft key, applied in the direction of measuring device, adopting mechanical device, mechanical measuring device, etc., can solve the problems of long detection time, low error rate, cumbersome operation, etc., achieve simple operation, fast detection, and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

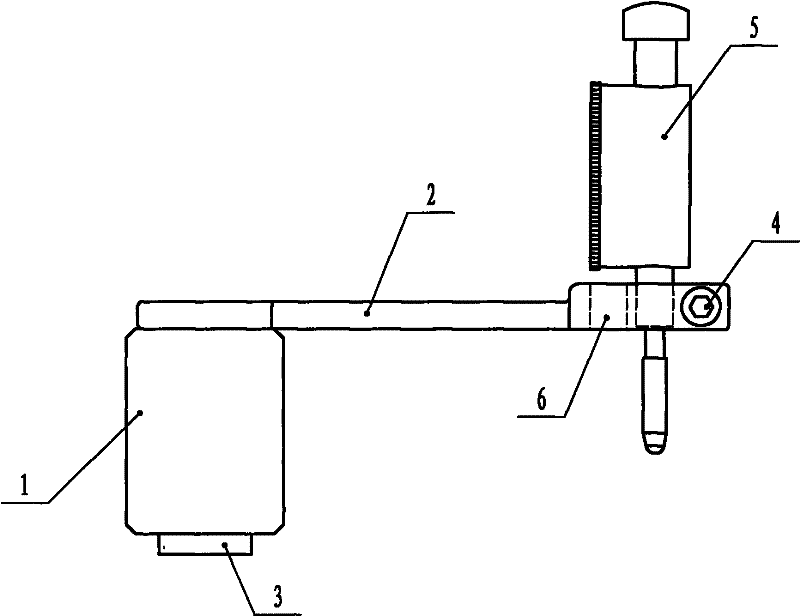

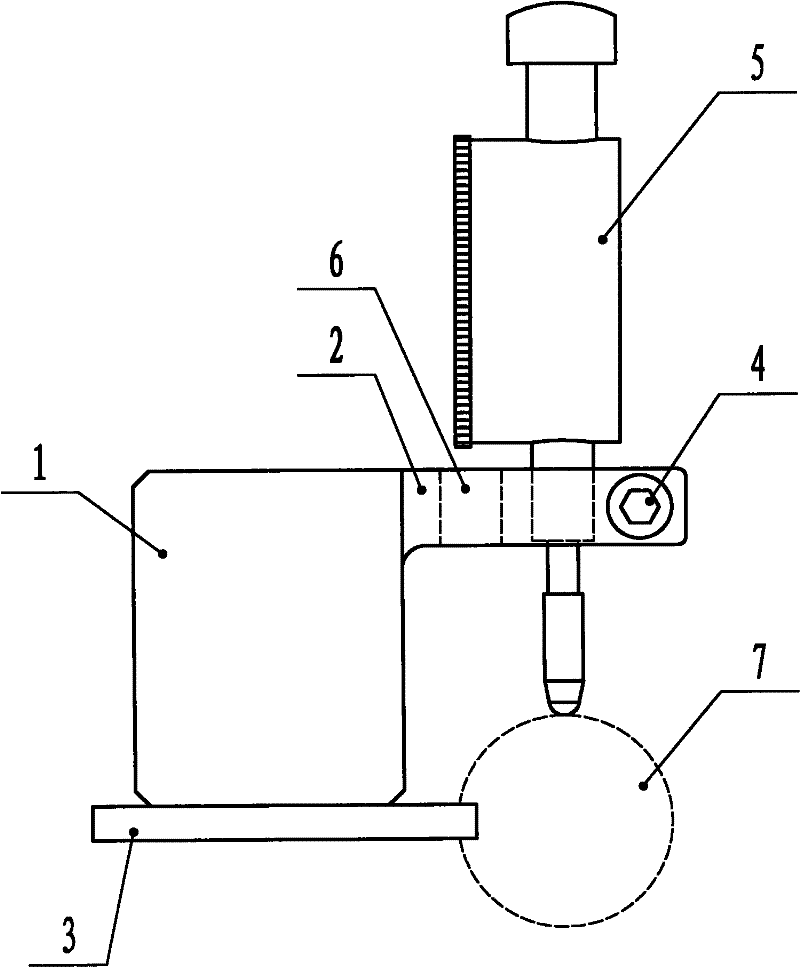

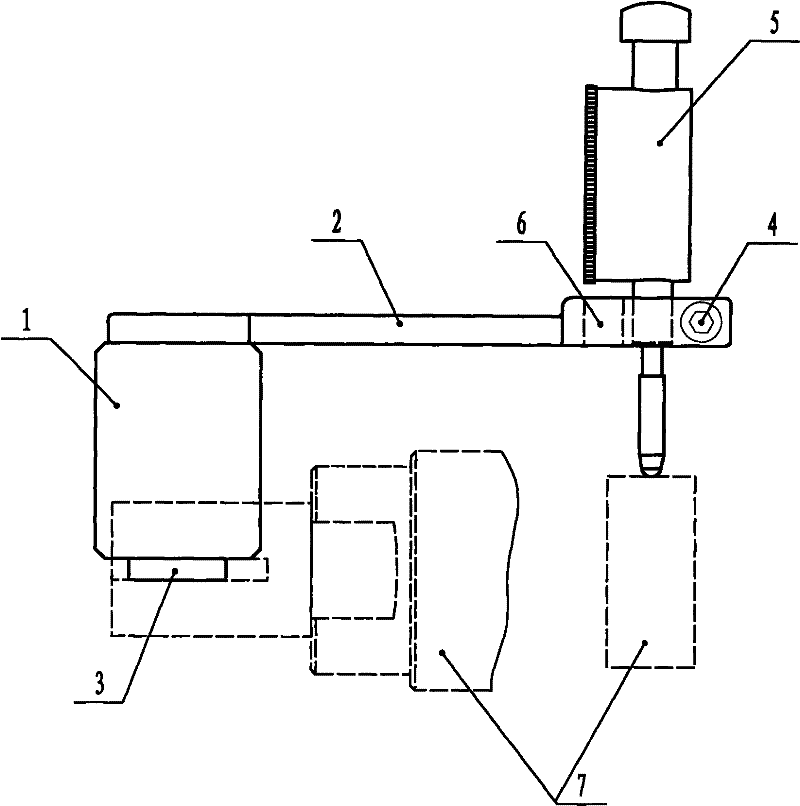

[0067] refer to figure 1 , a checker for detecting the symmetry of the crankshaft keyway of an automobile engine, comprising a table base 1, a positioning gauge block 3 and a dial indicator 5, the positioning gauge block 3 is a square block matched with the keyway of the measured crankshaft 7 without clearance, and the table base The lower end face of 1 is matched with the square block, the dial indicator 5 is connected with one side of the table base 1, and the measuring rod of the dial indicator 5 is perpendicular to the lower end face of the table base 1.

[0068] The thickness of the positioning gauge block 3 is set into multiple groups according to the tolerance size of the keyway of the measured crankshaft 7, and the interval between each group is 0.005mm. When measuring, it is necessary to select a positioning gauge block 3 that fits seamlessly with the keyway and insert it into the keyway to simulate the center plane of the keyway under test.

[0069] The dial gauge 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com