Biomass straw pellet burner

A biomass straw and burner technology, which is applied in the direction of combustion methods, combustion equipment, and solid fuel combustion, can solve the problems of insufficient utilization of straw-based biomass pellet fuels, and the inability to burn straws, etc., to achieve controllable and continuous combustion , The effect of reducing the degree of generation of ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

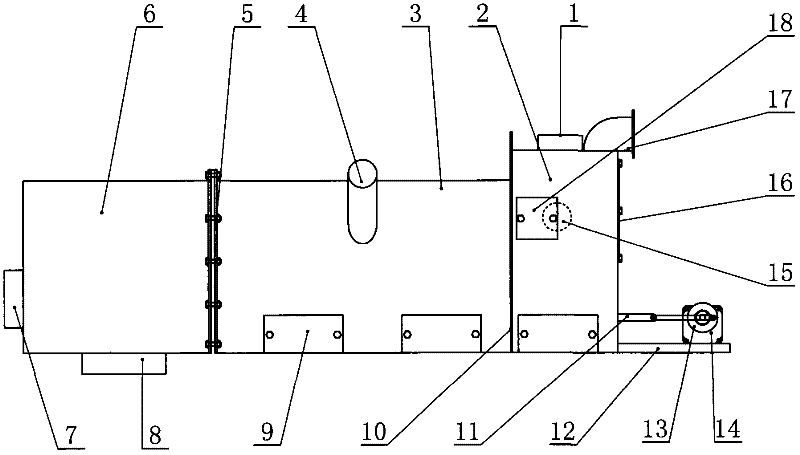

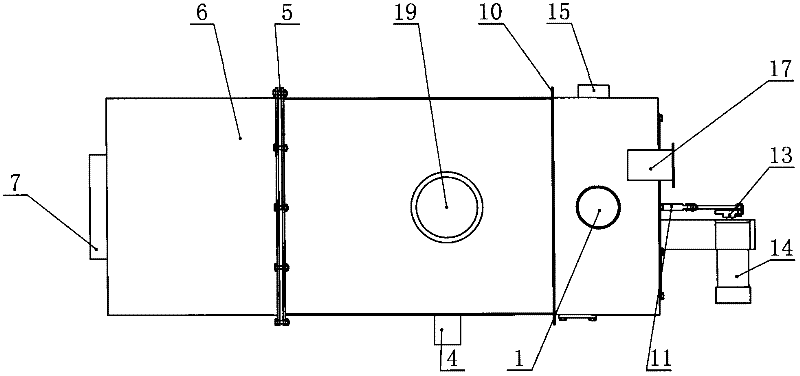

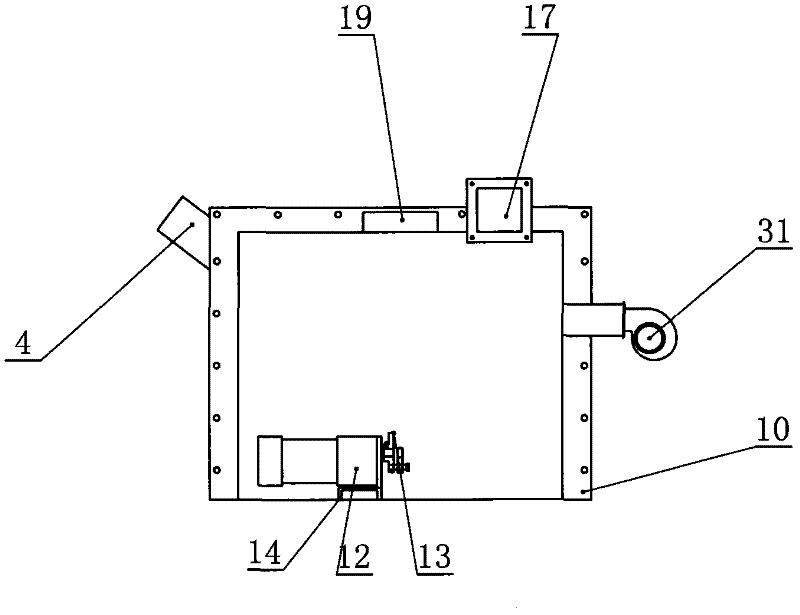

[0018] A biomass straw pellet burner, such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, including the furnace arch 3, the right end of the furnace arch 3 is fixedly connected to the burner material box 2 through the burner main flange 10, and the left end of the furnace arch 3 is fixed through the connecting flange 5 Connect the ash box 6, and the furnace arch 3 communicates with the burner material box 2 and the ash box 6 respectively. The feed port 1, the lower end of the drying box 20 is open, the drying box 20 communicates with the burner material box 2, the upper surface of the burner material box 2 is fixedly connected with an air inlet 17, and the rear surface of the burner material box 2 has an ignition port 15, An igniter 31 is installed in the ignition port 15, and a side inspection hole cover 18 is designed on the front surface of the burner mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com