A rotary contact assembly

A technology of contact assembly and contact arm, which is applied in the direction of contacts, electrical components, contact engagement, etc., can solve problems such as power distribution system paralysis, and achieve compact layout, good instantaneous current tolerance, and easy reset operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

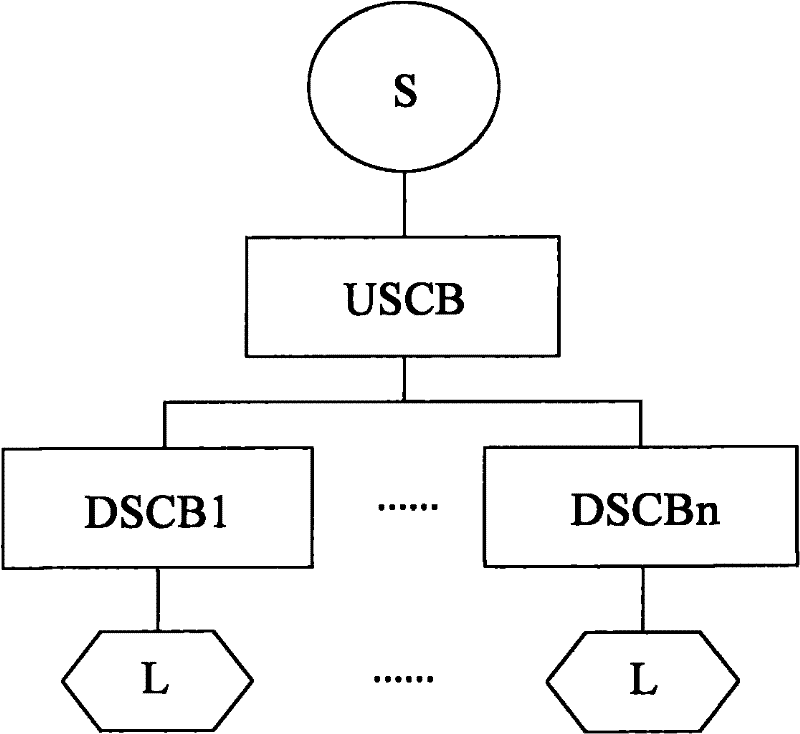

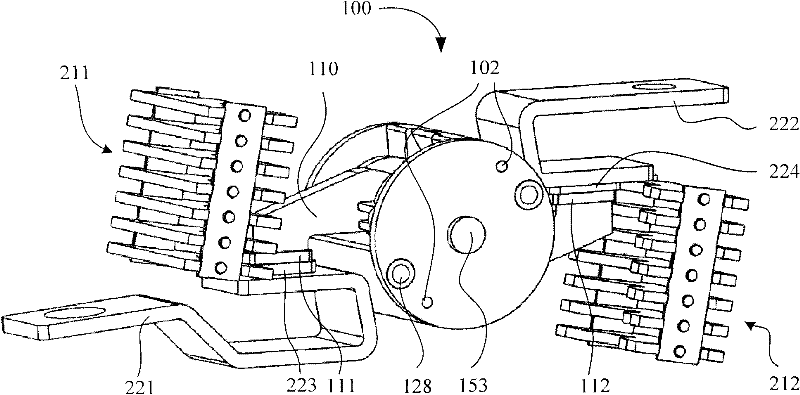

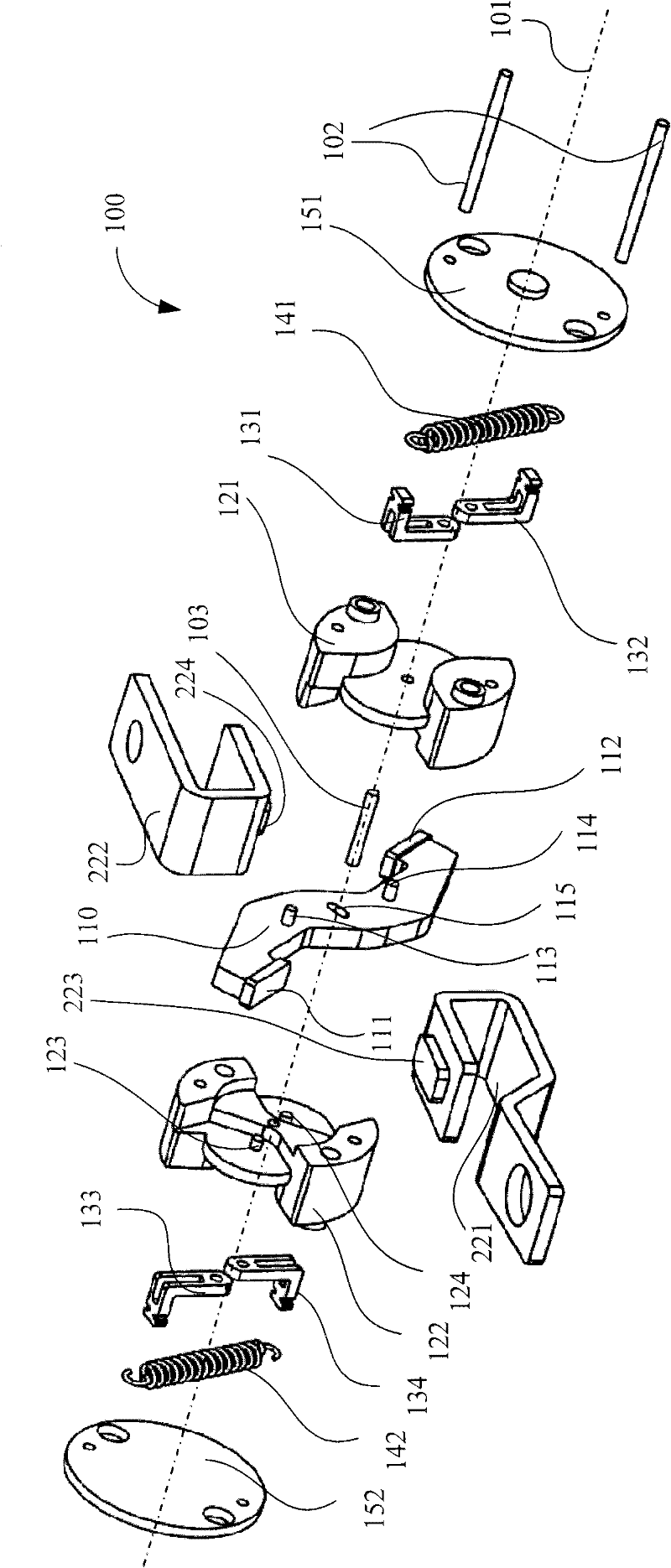

[0044] figure 2 A rotary contact assembly 100 according to one embodiment of the invention is shown. The rotary contact assembly 100 is usually installed in a figure 1 Inside the circuit breaker of the upstream circuit breaker USCB. To show more clearly, figure 2 Other parts of the circuit breaker are omitted. The rotary contact assembly 100 includes a contact arm 110 and a rotor 120 , wherein the movable contact 111 and the movable contact 112 are respectively located at two ends of the contact arm 110 . The first electrical conductor 221 (such as a power bar) and the second electrical conductor 222 (such as a load bar) are respectively located on two sides of the rotary contact assembly 100 and correspond to two ends of the contact arm 110 . When the rotary contact assembly 100 is in figure 2 In the closed position shown, the fixed contact 223 is engaged with the movable contact 111 and the fixed contact 224 is engaged with the movable contact 112, thus establishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com