Overtemperature and overcurrent protection module with manual reset in charged state

An overcurrent protection module and manual reset technology, applied in the direction of automatically disconnected emergency protection devices, emergency protection circuit devices, electrical components, etc., can solve problems such as tediousness, limited application range, and inability to adjust and control temperature at multiple points , to achieve the effect of reliable work, wide application range and modular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples are further explanations and descriptions of the present invention, and do not constitute any limitation to the present invention.

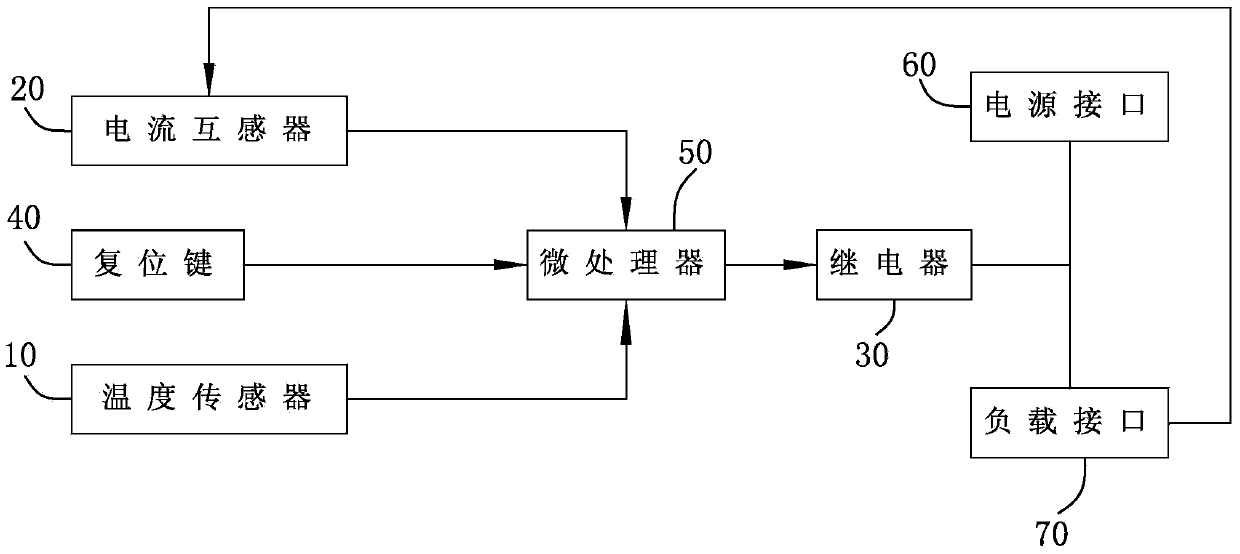

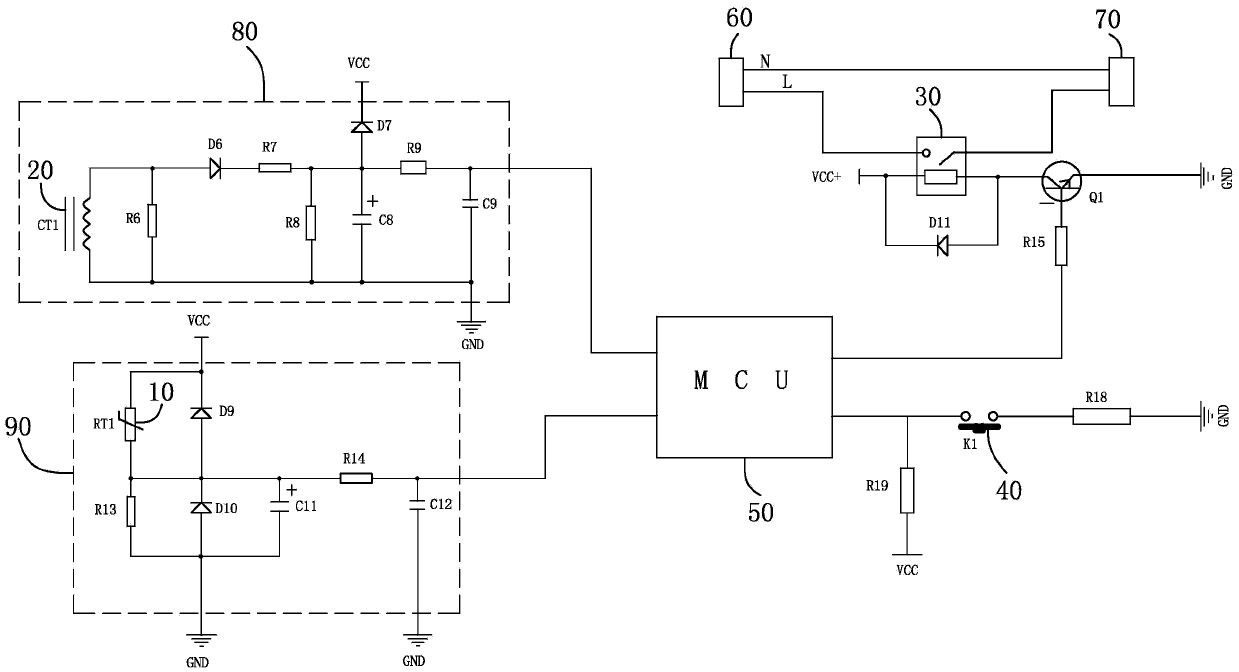

[0017] Refer to figure 1 , The over-temperature and over-current protection module that can be reset manually with power of the present invention includes a temperature sensor 10, a current transformer 20, a relay 30, a reset button 40, a microprocessor 50, a power interface 60, a load interface 70, a sampling circuit 80 and a signal Input circuit 90.

[0018] Such as figure 1 , figure 2 As shown, the temperature sensor 10 (RT1) is a non-contact temperature sensor, which is used to detect the temperature of the load. The temperature sensor can be a thermistor, a resistance temperature detector (RTD) or an IC temperature sensor. In this embodiment, the temperature sensor is a resistance temperature detector, which is connected to the microprocessor 50 through a signal input circuit 90 , Send the measured load temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com