Separating anti-drop moving contact for molded case circuit breaker

A technology of molded case circuit breaker and moving contact piece, which is applied in the directions of circuit breaker contacts and circuit breaker parts, etc., can solve the problems of limited breaking current, difficulty in preventing contacts from falling, and limited improvement space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

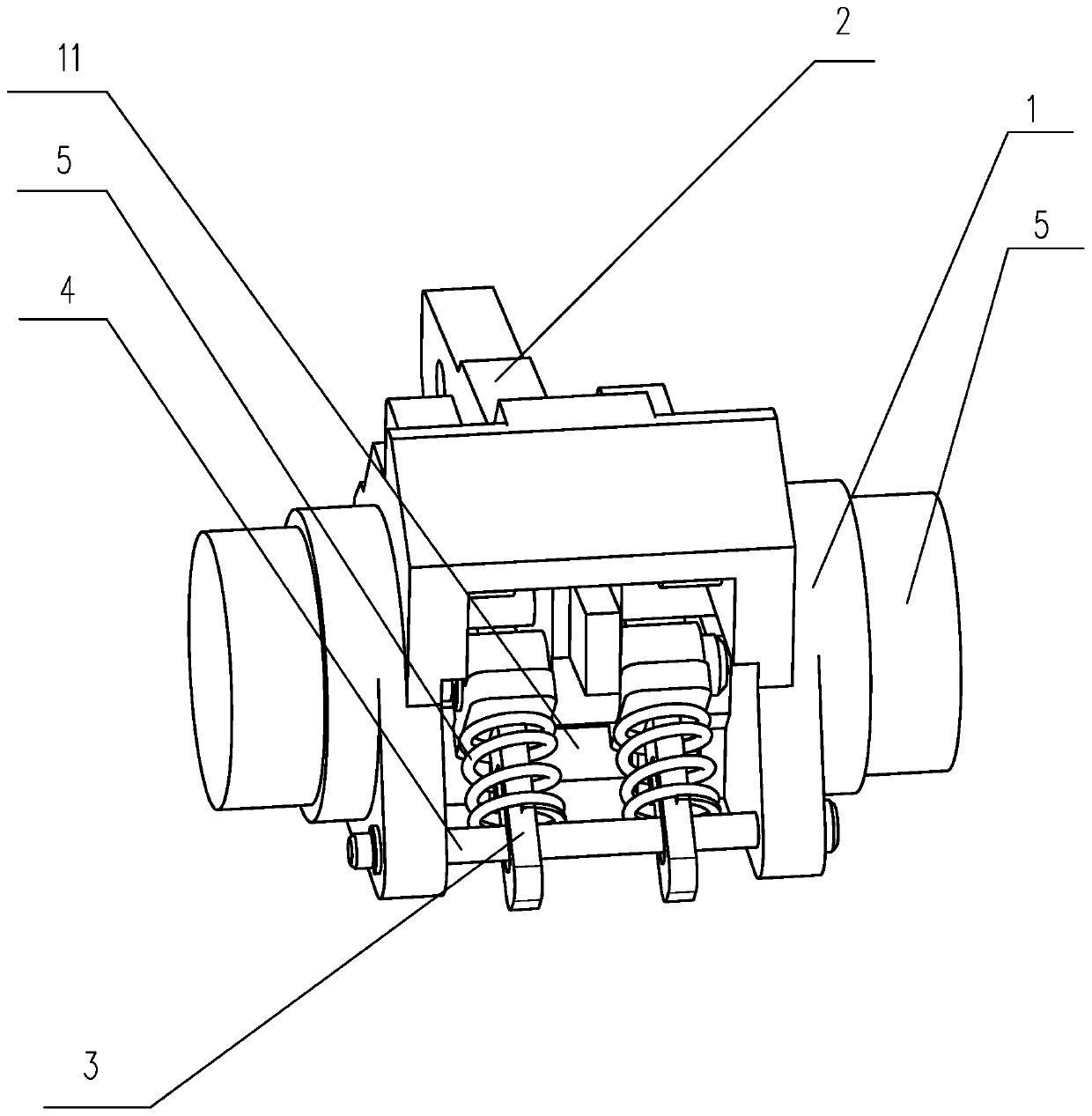

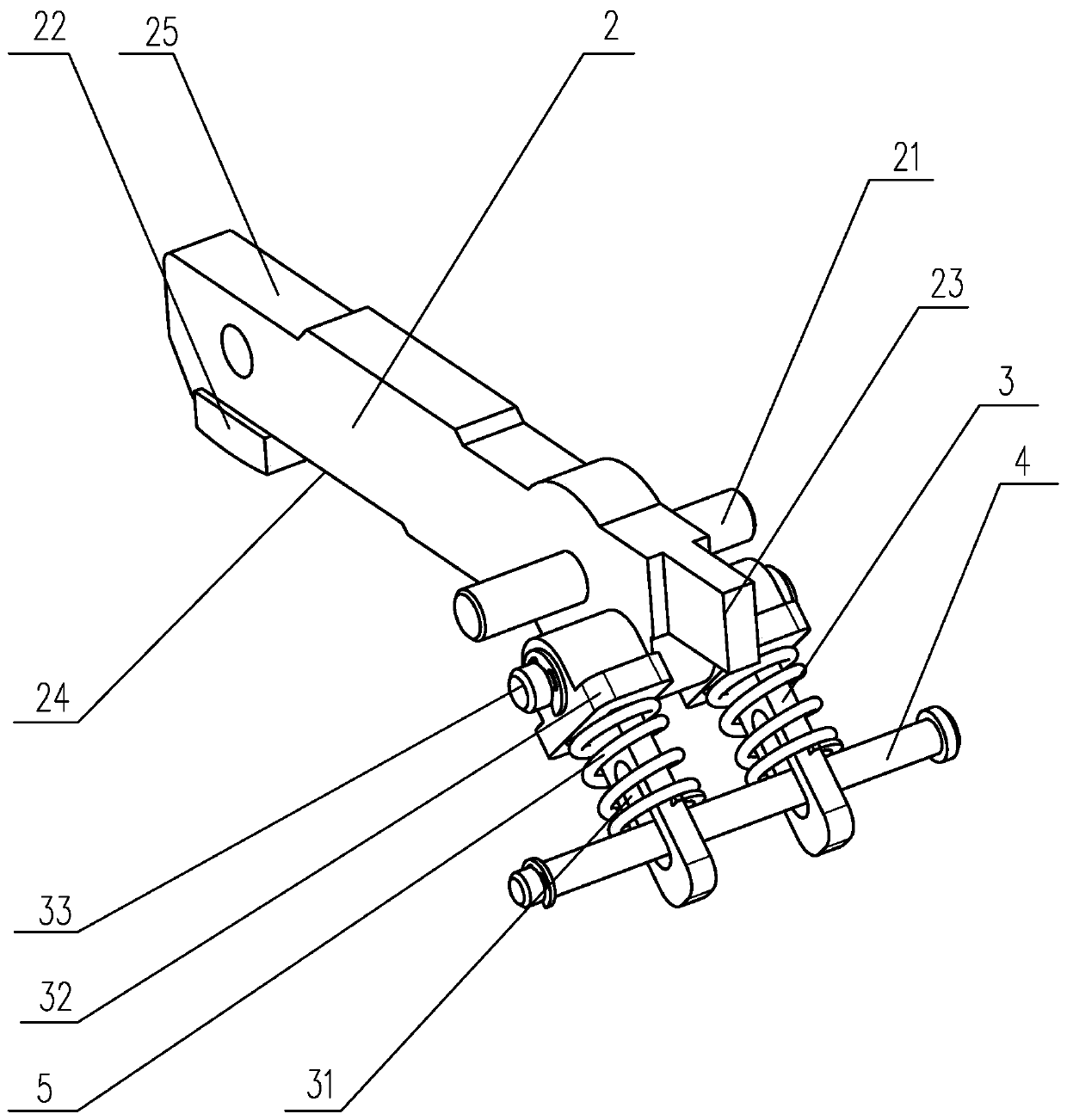

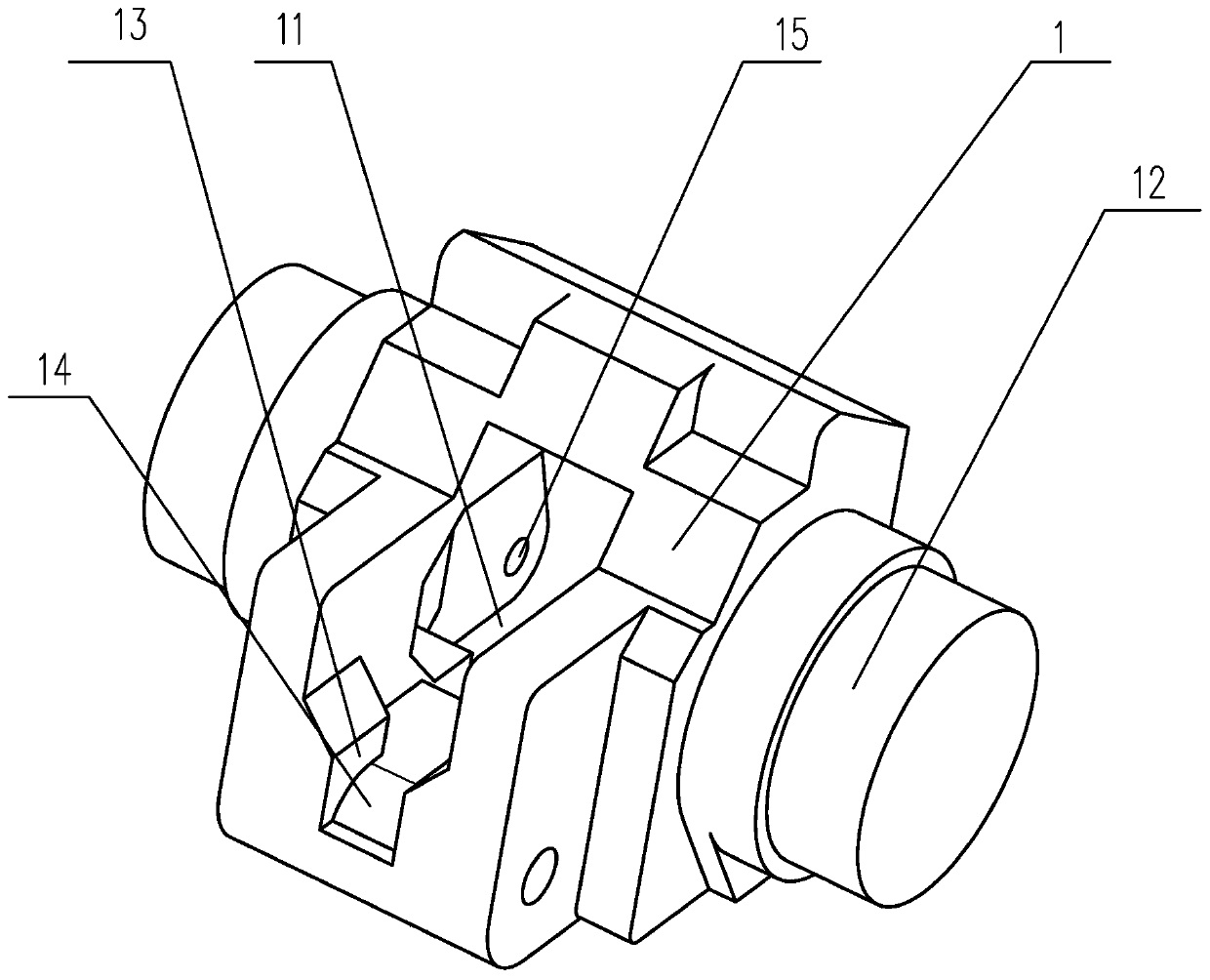

[0035] by Figure 1 to Figure 3 It can be seen that a breaking and anti-drop moving contact piece for a molded case circuit breaker is disclosed, which includes a connecting seat 1, two sides of the connecting seat 1 are formed with hinged protrusions 12 for articulation, and the upper edge of the connecting seat 1 An installation through groove 11 is formed in the front and rear direction, and a movable contact rod 2 is arranged in the installation through groove 11, and the movable contact rod 2 is hingedly arranged in the installation through groove 11 through a swing shaft 21. Both sides of the installation through groove 11 A swing groove is formed on the wall, the swing shaft 21 is inserted into the swing groove to form a movable contact rod 2 that swings in the installation through groove 11, and the front end of the movable contact rod 2 extends outside the installation through groove 11 and is arranged There is a moving contact piece 22, the rear end of the moving conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com