Power distribution system

A technology of distribution system and power, applied in the field of power distribution system, can solve the problems of inconvenient maintenance and complex structure, and achieve the effect of avoiding potential safety hazards, compact overall structure and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

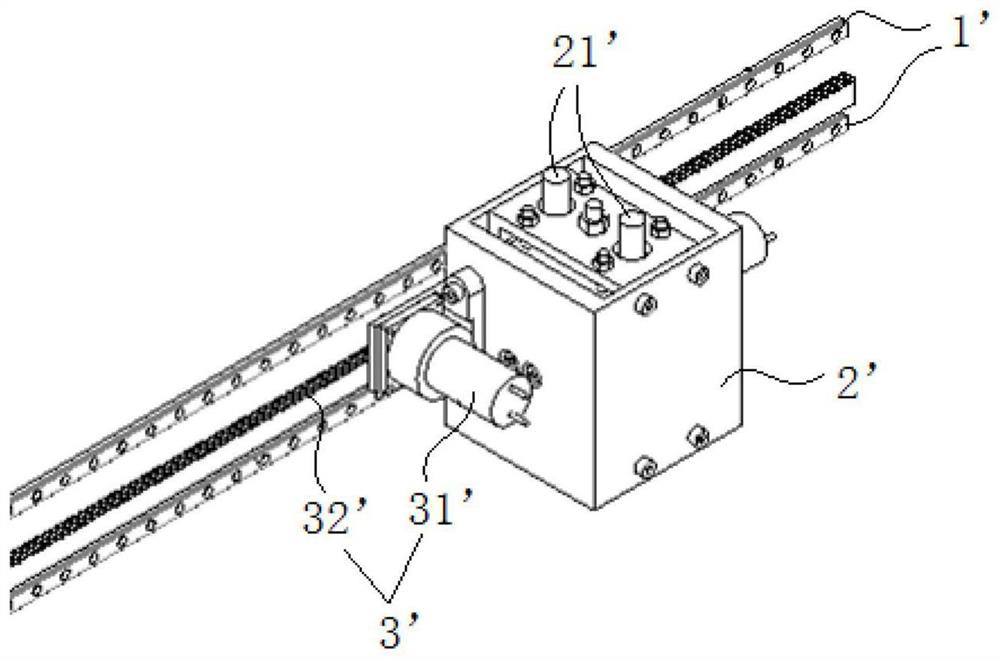

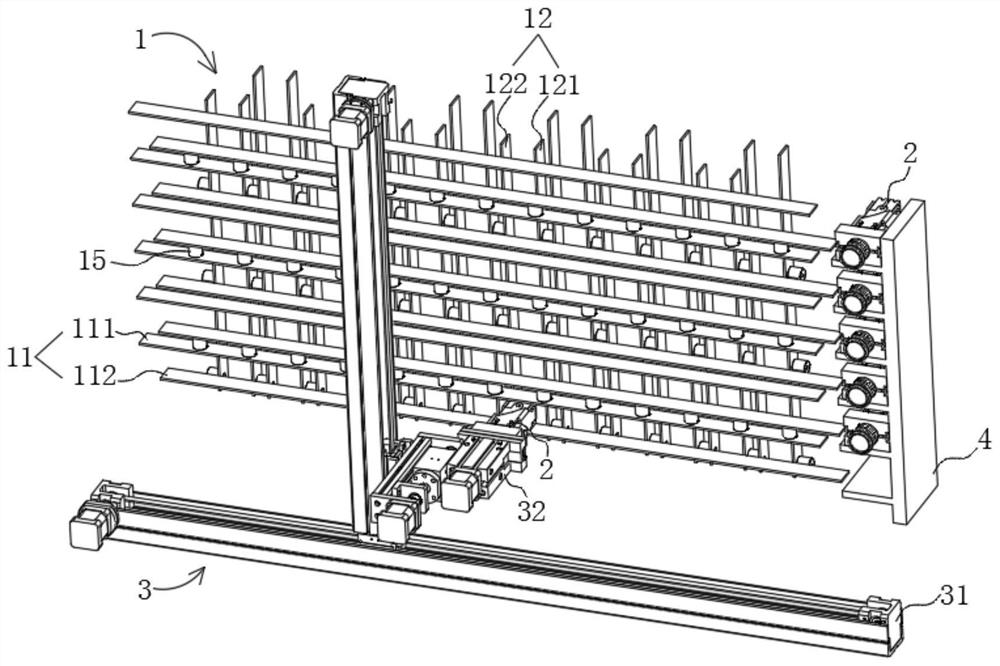

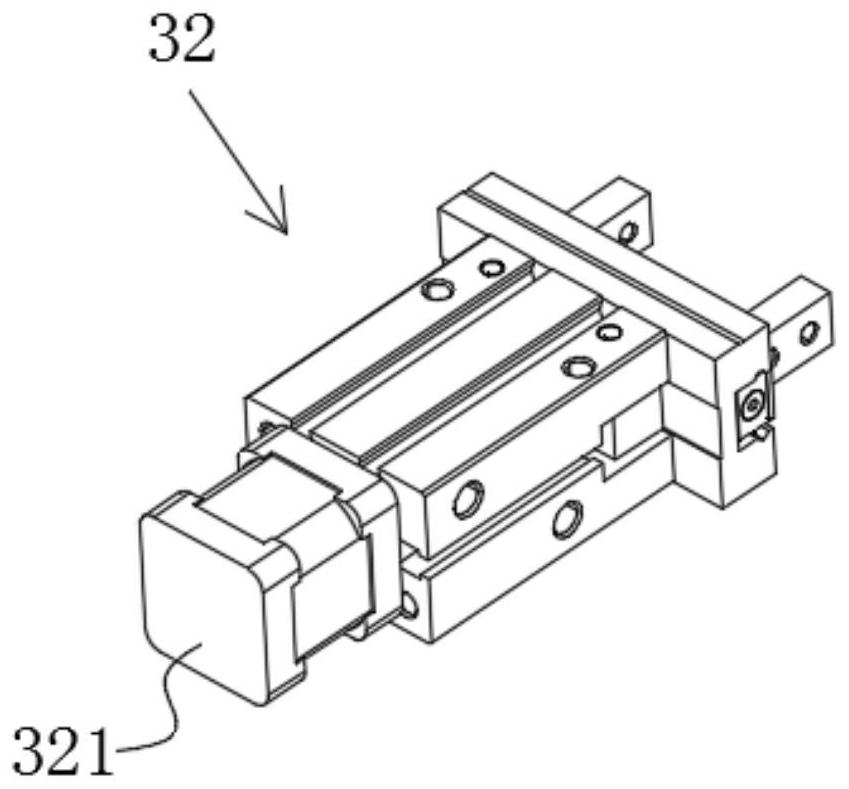

[0063] Such as Figure 2-3 As shown, this embodiment provides a power distribution system, the power distribution system includes a copper bar assembly 1, a plurality of connectors 2 and a moving assembly 3, the copper bar assembly 1 includes multiple sets of input copper bars 11 and multiple sets of output copper bars 12. The output copper bar 12 is arranged on one side of the input copper bar 11, a plurality of connectors 2 are arranged on the side of the copper bar assembly 1, and the moving assembly 3 includes a gripper 32 and a driving module 31 for driving the gripper 32 to move , specifically, the input copper bars 11 of this embodiment are connected to the charging power source, and the output copper bars 12 are connected to the charging terminals. Every two sets of input copper bars 11 are separated by insulators 15, and every two sets of output copper bars 12 are separated. Separated by insulators 15, further, a bracket 4 is arranged on the side of the copper bar ass...

Embodiment 2

[0083] Such as Figure 15-16 As shown, the difference between the power distribution system of the present embodiment and the first embodiment is that the linkage mechanism in the connector 2 of the present embodiment and each limit member on the limit seat 27 are different from the first embodiment. The link mechanism of the present embodiment includes two push rods 221, the first end of the push rod 221 is configured with an electrode, and the second end of the push rod 221 is hinged to the drive rod 24. Further, the link mechanism of this embodiment also includes two link rods 222, two connecting rods 222 and two push rods 221 form a hinge four-bar mechanism, the first end of the connecting rod 222 is hinged with the first end of the corresponding push rod 221, and the second end of the connecting rod 222 is configured as a fixed At the hinged end, the driving member 321 drives the push rod 221 in each linkage mechanism to move by means of the driving rod 24 .

[0084] Fur...

Embodiment 3

[0087] Such as Figure 19 As shown, the difference between the power distribution system of this embodiment and Embodiment 1 or 2 is that this embodiment also has multiple sets of parallel copper bars 13 corresponding to the output copper bars 12 on one side of the output copper bars 12, The parallel copper bars 13 are electrically connected to the output copper bars 12 in one-to-one correspondence through conductive elements 14 . Specifically, the output copper bar 12 is arranged on one side of the input copper bar 11, and the parallel copper bar 13 is arranged on one side of the output copper bar 12, and the parallel copper bar 13 and the output copper bar 12 pass through the conductive member in one-to-one correspondence 14 connection, the conductive part 14 can be a copper bar or a wire, so, as Figure 20 As shown, a set of mobile components 3, brackets 4 and multiple connectors 2 can be arranged on one side of the parallel copper bars 13, and a set of output copper bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com