L-shaped oiling machine capable of leading out oil pipe from lower part of machine

A fuel dispenser, L-shaped technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of oil pipe damage, affect the appearance, and the appearance is not beautiful, and achieve high safety performance, uniform and reliable force, and pulling action. Handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

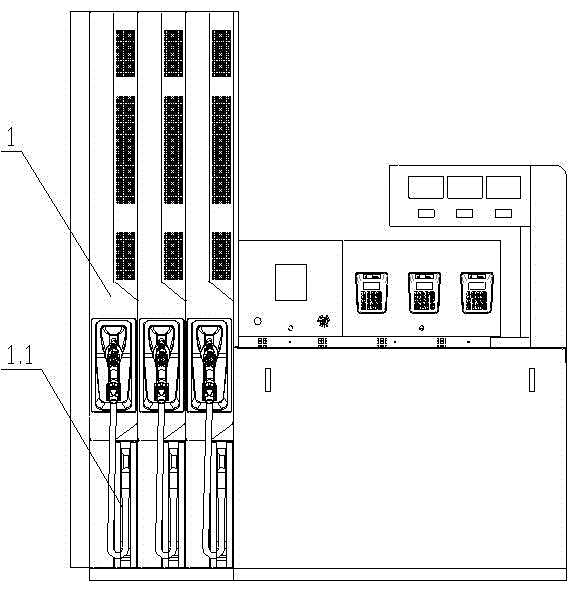

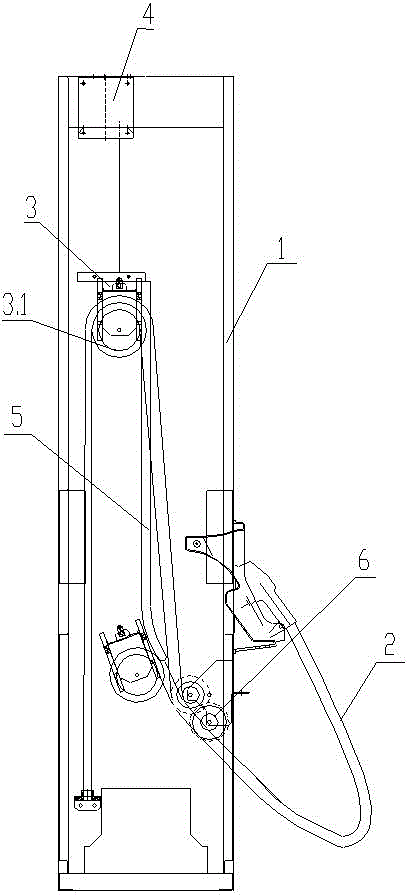

[0022] see Figure 1~4 , the present invention relates to an L-shaped lower pipe refueling machine, the refueling machine includes an organic body 1, a pipe outlet groove 1.1 is arranged under the body 1, and the oil pipe 2 located in the body 1 is led out to the Body 1 outside;

[0023] Specifically, the oil pipe 2 located in the body 1 is hung on the movable pulley 3.1, and the movable pulley 3.1 is hung on the movable pulley bracket 3, and the movable pulley bracket 3 is hung on the rubber hose balancer 4. Preferably, the rubber hose balancer 4 It includes a ratchet and pawl mechanism composed of a ratchet 4.3 and a pawl 4.4. The shaft of the ratchet 4.3 is wound with a wire rope 4.2, and the free end of the wire rope 4.2 is connected with a hook 4.1. The hook 4.1 is hooked on the movable pulley bracket 3; there is a reset spring 4.5 One end is connected to the body 1, and the other end is connected to the ratchet 4.3; when the oil pipe 2 is pulled outward, the oil pipe 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com