Anticorrosive and antirust electricity transmission iron tower

A transmission tower, anti-corrosion and anti-rust technology, applied in towers, building types, buildings, etc., can solve the problems of high risk factor, inability to reduce stress corrosion of iron towers, short shelf life of anti-rust treatment process, etc., and achieve long shelf life and high cost performance. , The effect of resetting the job is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

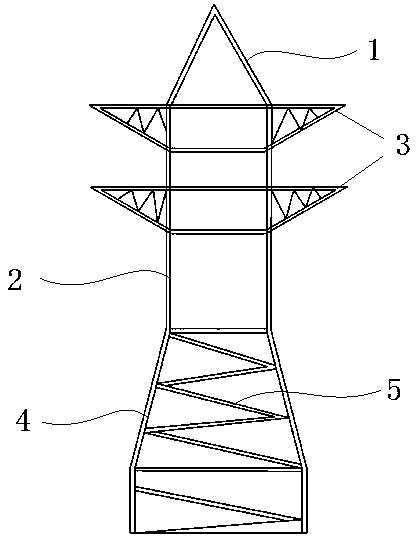

[0012] Such as figure 1 As shown, an anti-corrosion and anti-rust power transmission tower includes a tower tip 1, a tower waist 2, a cross arm 3, and a tower base enclosure 4, and a plurality of reinforcing ribs 5 are arranged inside the tower base enclosure 4. The surface of the spire 1, the tower waist 2 and the cross arm 3 is provided with an inner coating and an outer coating, the inner coating is an aluminum spray coating, and the outer coating is an epoxy resin coating.

[0013] A paint layer is provided on the surface of the tower base 4 and the reinforcing rib 5 .

[0014] The thickness of the inner coating is 35-40um, and the thickness of the outer coating is 30-35um.

[0015] The above is only a preferred embodiment of the present invention, it should be pointed out that for those of ordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com