A kind of anti-counterfeiting paper containing single-level grayscale gradient watermark and its manufacturing method

A manufacturing method and single-layer technology, applied in papermaking, textile and papermaking, fiber raw material processing, etc., can solve the problems of single white watermark effect, no machine readable conditions, poor watermark stability, etc., and achieve better anti-counterfeiting effect and anti-counterfeiting effect. Improved effect, stable grayscale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

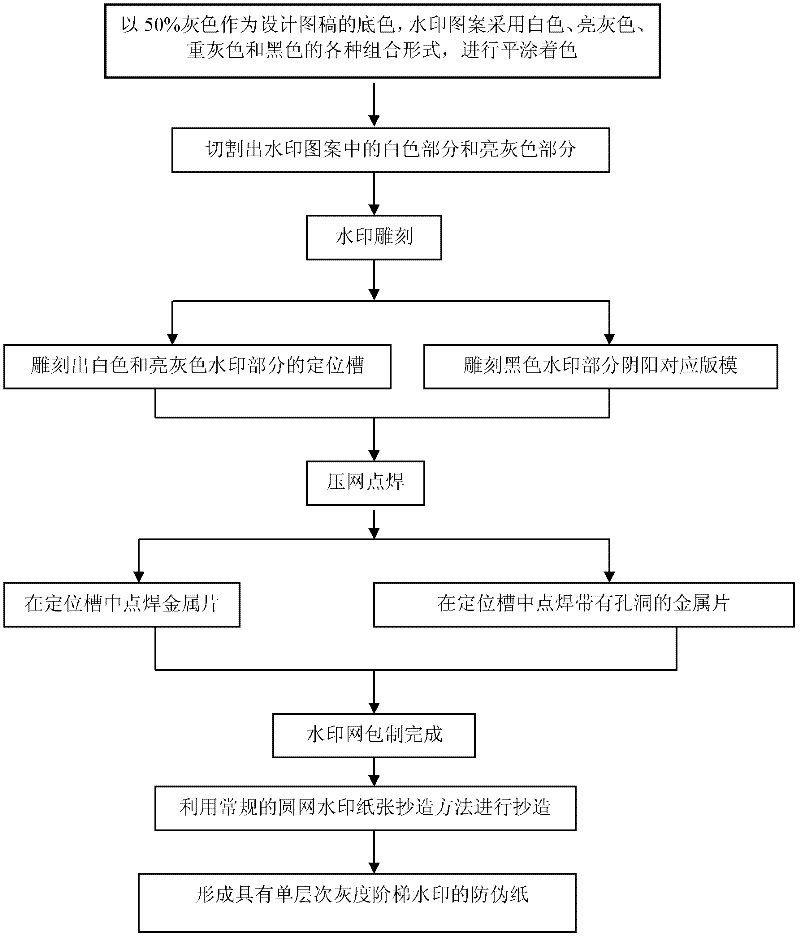

Method used

Image

Examples

Embodiment 1

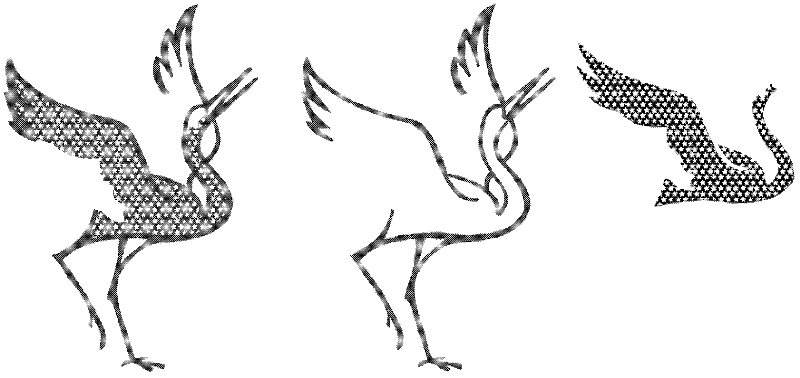

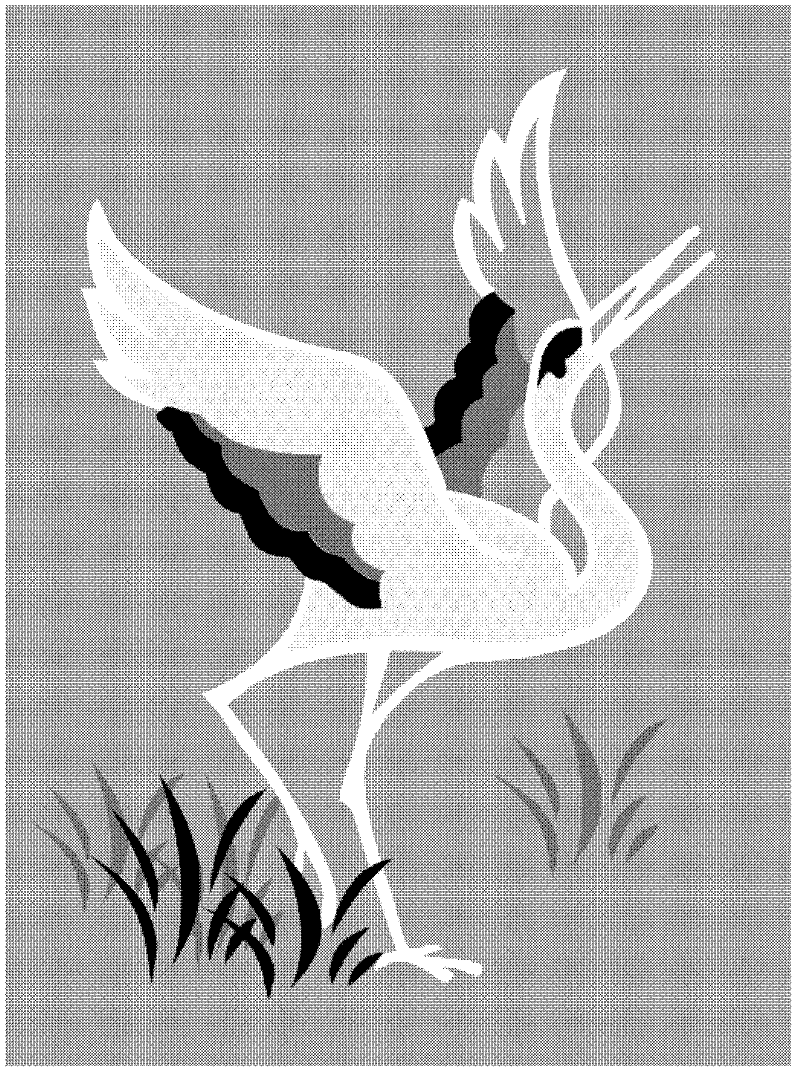

[0058] This embodiment provides a method for manufacturing anti-counterfeit paper containing a single-level gray-scale gradient watermark with two grayscale gradients, wherein the above-mentioned watermark pattern is a circular square-hole money, and the outer circumference of the circular square-hole money pattern is And the four sides of the central square hole are all white areas, and the other central parts are bright gray areas.

[0059] The manufacture method of this anti-counterfeit paper comprises the following steps:

[0060] Use a silver-plated copper alloy plate with a thickness of 0.6mm as the watermark metal sheet, cut the watermark metal sheet into a circle with a square hole in the center according to the watermark pattern, and then follow the watermark pattern to correspond to the bright gray area in the circular watermark metal sheet Holes are cut in part of the hollow area to form metal sheet 2 in the hollow area, and part of the metal sheet 1 corresponding t...

Embodiment 2

[0065] This embodiment provides a method for manufacturing anti-counterfeiting paper with a single-level gray-scale gradient watermark containing three gray-scale gradients, wherein the above-mentioned watermark pattern is two overlapping circular square hole coins, and the left circular square hole The outer circumference of the hole coin pattern and the four sides of the central square hole are all white areas, and the other central parts are bright gray areas. A part of the right circular square hole coin pattern is located under the left circular square hole coin and cannot be seen. In the part, the outer circumference and the four sides of the central square hole are all black areas, and the other central parts are not provided with watermark patterns, which are the same as the paper.

[0066] The manufacture method of this anti-counterfeit paper comprises the following steps:

[0067] Use a silver-plated copper alloy plate with a thickness of 0.6mm as the watermark metal...

Embodiment 3

[0072] This embodiment provides a method for manufacturing anti-counterfeiting paper with a single-level gray-scale gradient watermark containing 4 gray-scale gradients, wherein the above-mentioned watermark pattern is two overlapping circular square-hole coins, and the left circular square hole The outer circumference of the hole coin pattern and the four sides of the central square hole are all white areas, and the other central parts are bright gray areas. A part of the right circular square hole coin pattern is located under the left circular square hole coin and cannot be seen. In the part, the outer circumference and the four sides of the central square hole are all black areas, and the other central parts are heavy gray areas.

[0073] The manufacture method of this anti-counterfeit paper comprises the following steps:

[0074] Use a silver-plated copper alloy plate with a thickness of 0.6mm as the watermark metal sheet, cut the watermark metal sheet into a shape of two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com