A rotary engine and its rotor part

A rotary engine and rotor technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems of not being able to take advantage of the advantages of the rotary engine, limit the output speed of the rotary engine, and the complicated structure of the rotary engine, so as to achieve convenient installation and application , simple structure, high possibility of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0041] For the convenience of description, the following describes the rotor part while describing the overall structure of the rotary engine, and does not describe the rotor part separately.

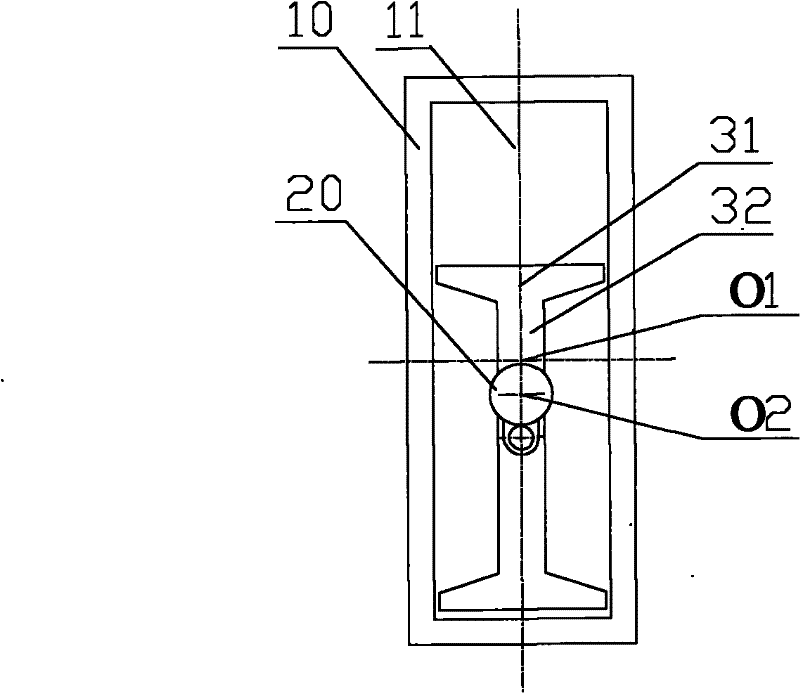

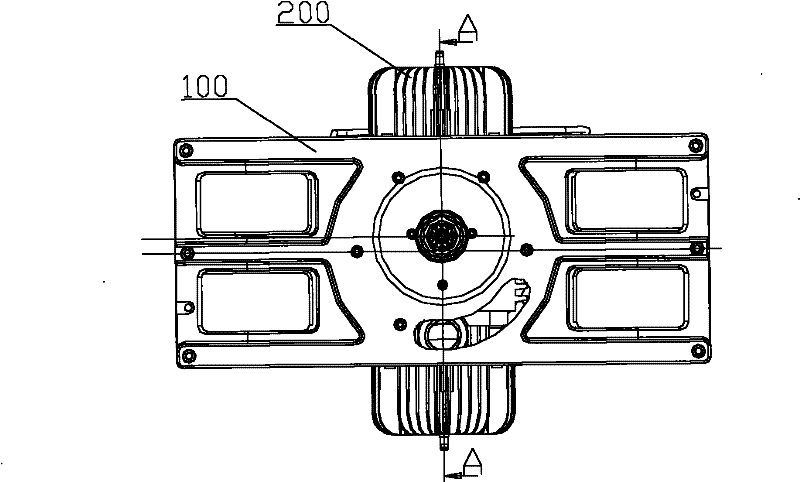

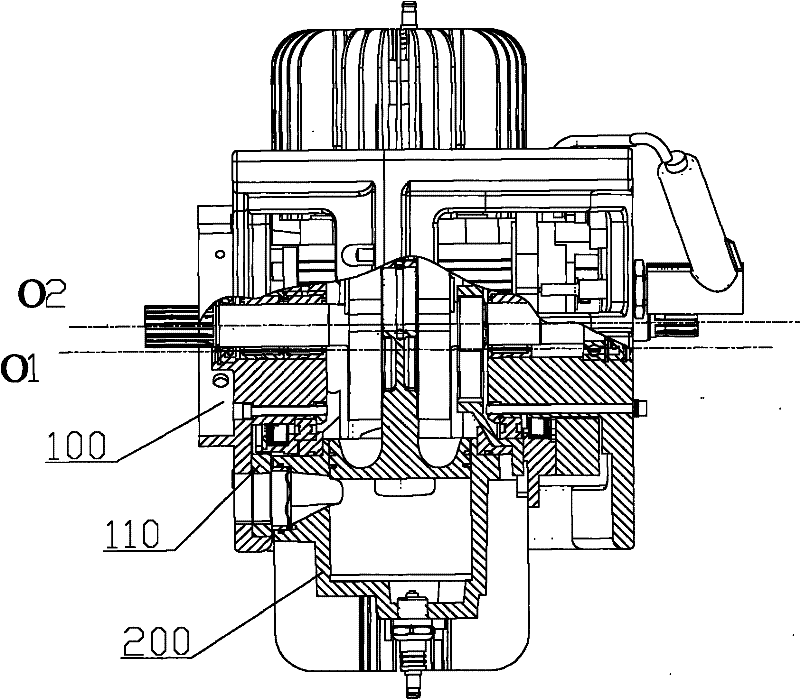

[0042] Please refer to figure 2 and image 3 , figure 2 is a schematic structural diagram of a rotary engine provided by an embodiment of the present invention, image 3 yes figure 2 Middle A-A sectional view. The rotary engine provided in the embodiment includes a stator part 100 and a rotor part 200 , the stator part 100 is fixed to a predetermined foundation, and the rotor part 200 can rotate relative to the stator part 100 . The structure of the rotor portion 200 will be described in detail below.

[0043] Please...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com