fuel injection control system

A fuel injection and control system technology, applied in the direction of fuel injection control, electrical control, engine control, etc., can solve the problems of too rich and too lean combustion state, and cannot always monitor the oxygen sensor, etc., to prevent excessive enrichment or delease Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

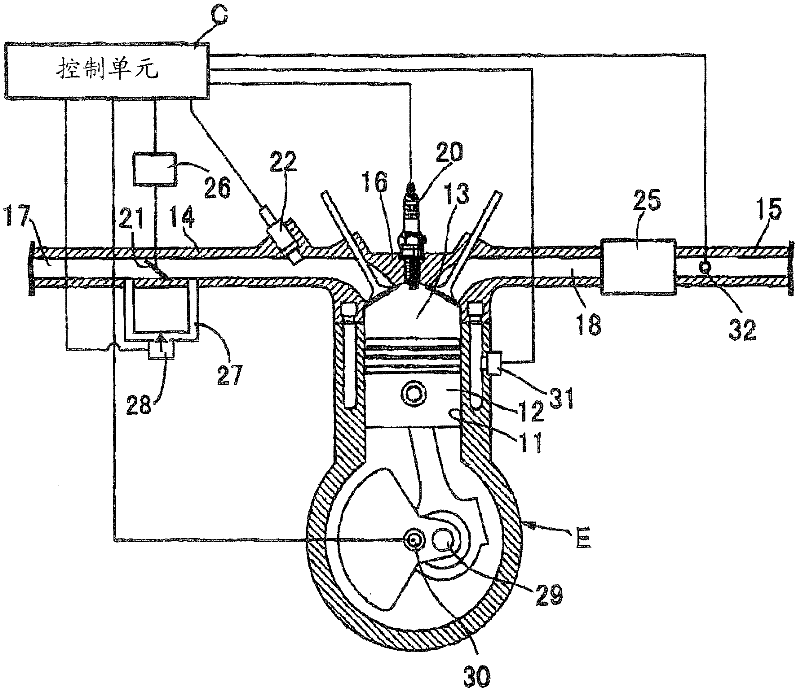

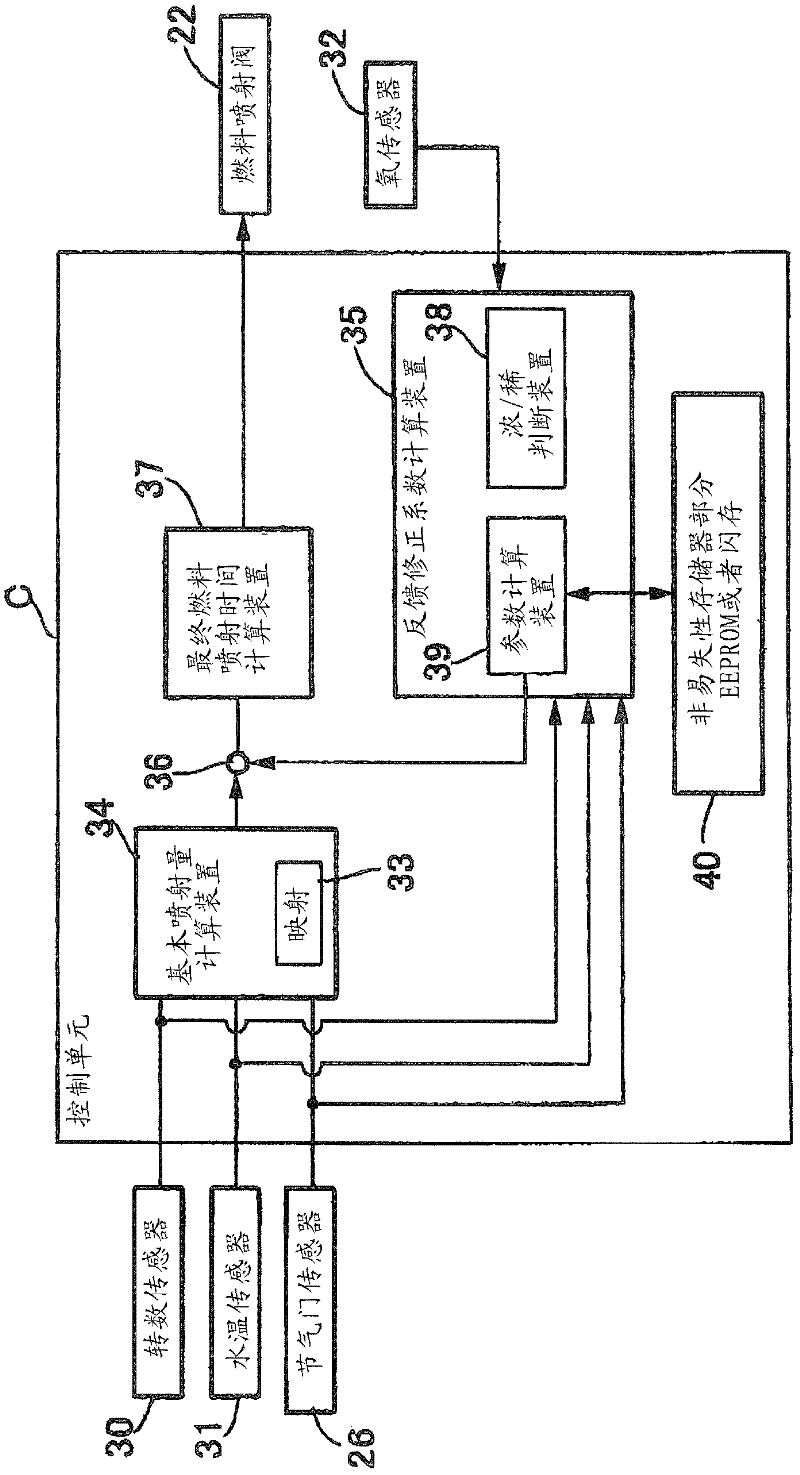

[0074] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. figure 1 is a block diagram showing the configuration of a fuel injection control system for an internal combustion engine according to an embodiment of the present invention. A piston 12 is slidably fitted in a cylinder bore 11 of a water-cooled internal combustion engine E mounted on a motorcycle. An intake device 14 for supplying an air-fuel mixture to a combustion chamber 13 and an exhaust device 15 for exhausting exhaust gas from the combustion chamber 13 are connected to a cylinder head 16 of the internal combustion engine E with an upper portion of the piston 12 facing the combustion chamber 13 . An intake passage 17 is formed in the intake device 14 , and an exhaust passage 18 is formed in the exhaust device 15 . A spark plug 20 with a front end facing the combustion chamber 13 is attached to the cylinder head 16 .

[0075] The intake device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com