Connection changing method for low-flame-point material pipeline

A technology for pipes and materials, which is applied in the field of low-flame point material pipeline connection method and internal blocking device, can solve the problems of difficult engineering, long time, and difficult disposal of low-flame point waste materials, so as to reduce engineering difficulty and ensure absolute sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

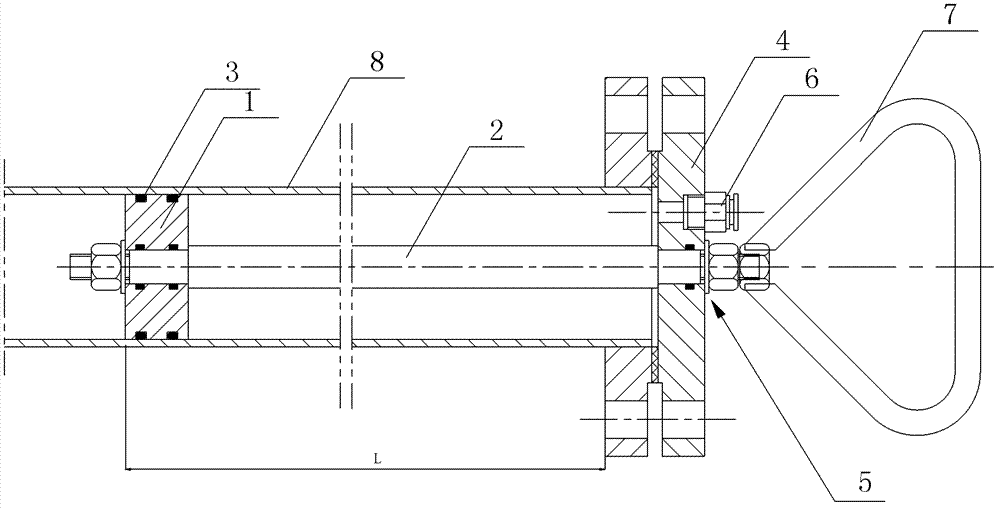

[0028] Embodiment: An internal plugging device used in the reconnection of a low-flame point material pipeline, including a piston 1 capable of matching the inner wall of a low-flame point material pipeline, a piston rod 2 connected to the piston 1 at one end, and a flange blind cover 4. Among them, the other end of the piston rod 2 is provided with a piston rod handle 7, the piston 1 is provided with a sealing ring 3 in the circumferential direction, and the flange blind cover 4 is provided with a piston rod through hole 5 and a hose through hole 6, which become the internal plug of the present invention. device.

[0029] The method for reconnecting the low-flame point material pipeline of the present invention is introduced below in conjunction with the above-mentioned internal blocking device, which includes the following steps:

[0030] Step 1) Backflow the low-flame point material in the low-flame point material pipeline (that is, flow out the low-flame point material in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com