New Die Casting Machine

A die-casting machine and a new type of technology, applied in the field of die-casting machinery and extrusion casting, can solve the problems of not setting the application function of the extrusion die-casting die, unable to meet the extrusion die-casting process, etc., to achieve timely extrusion feeding and prevent flying. edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

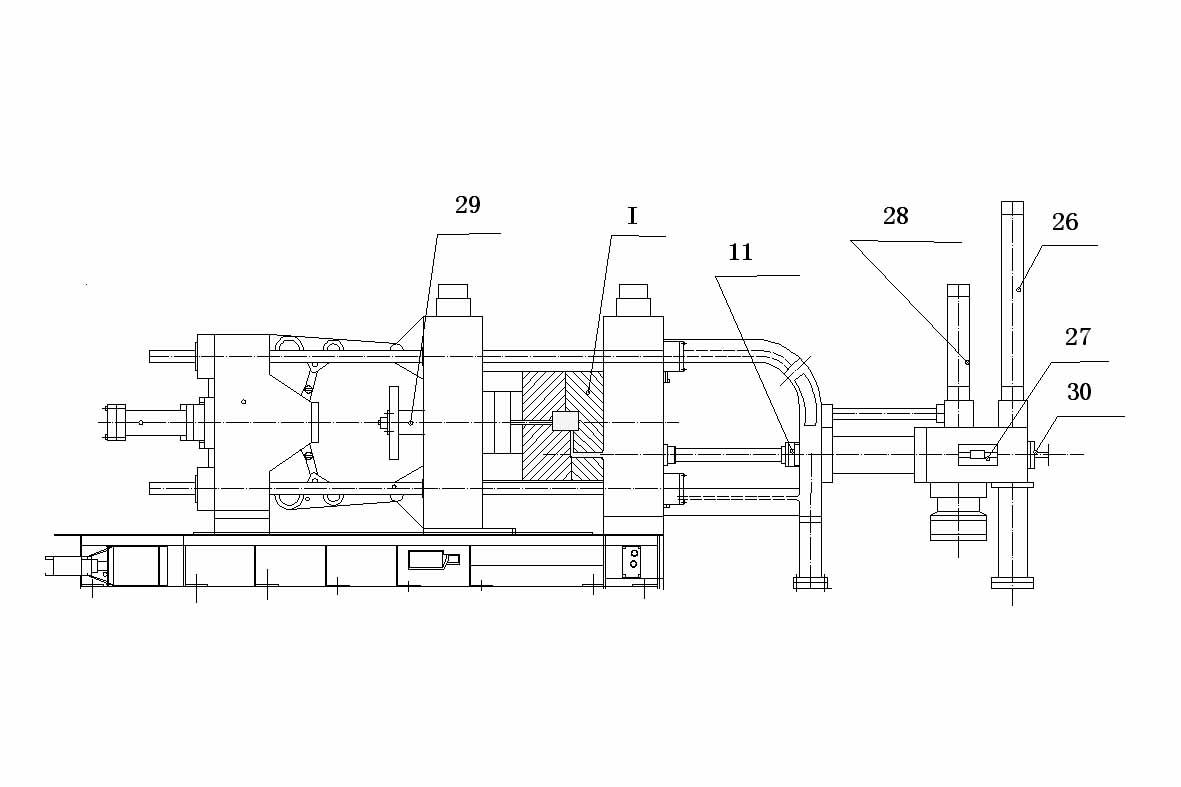

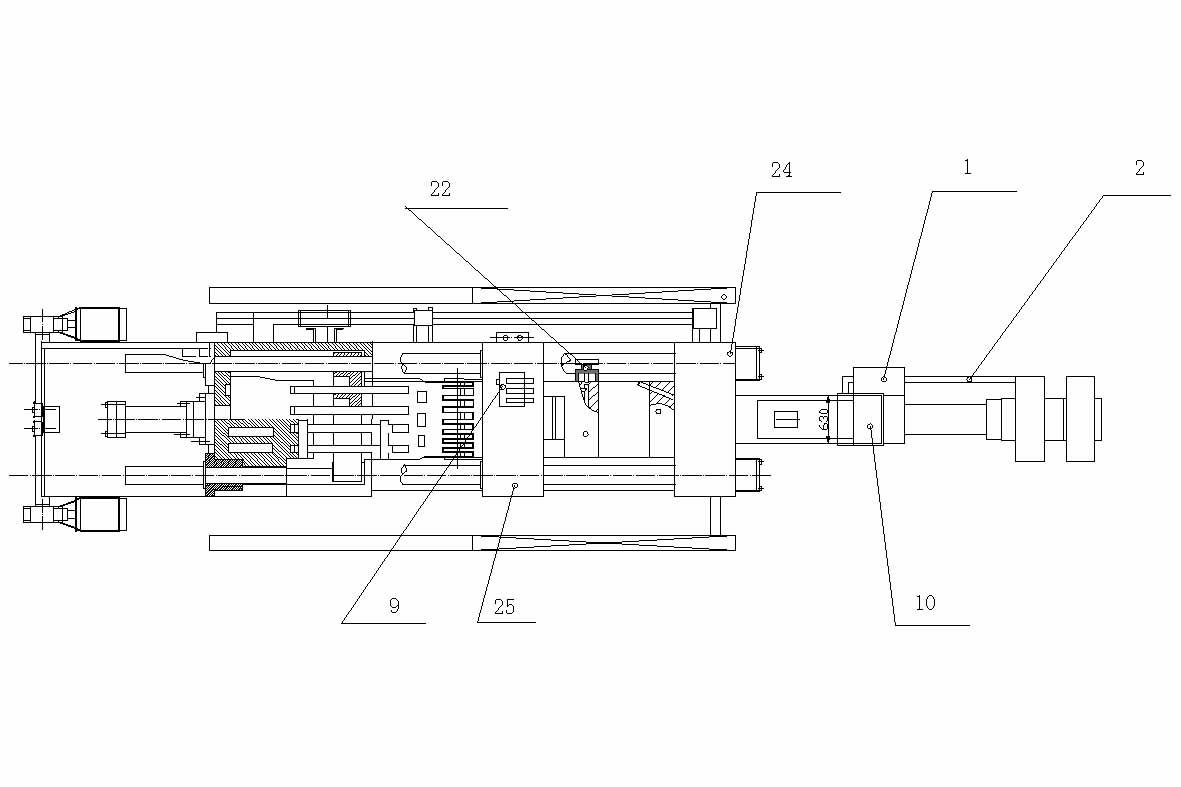

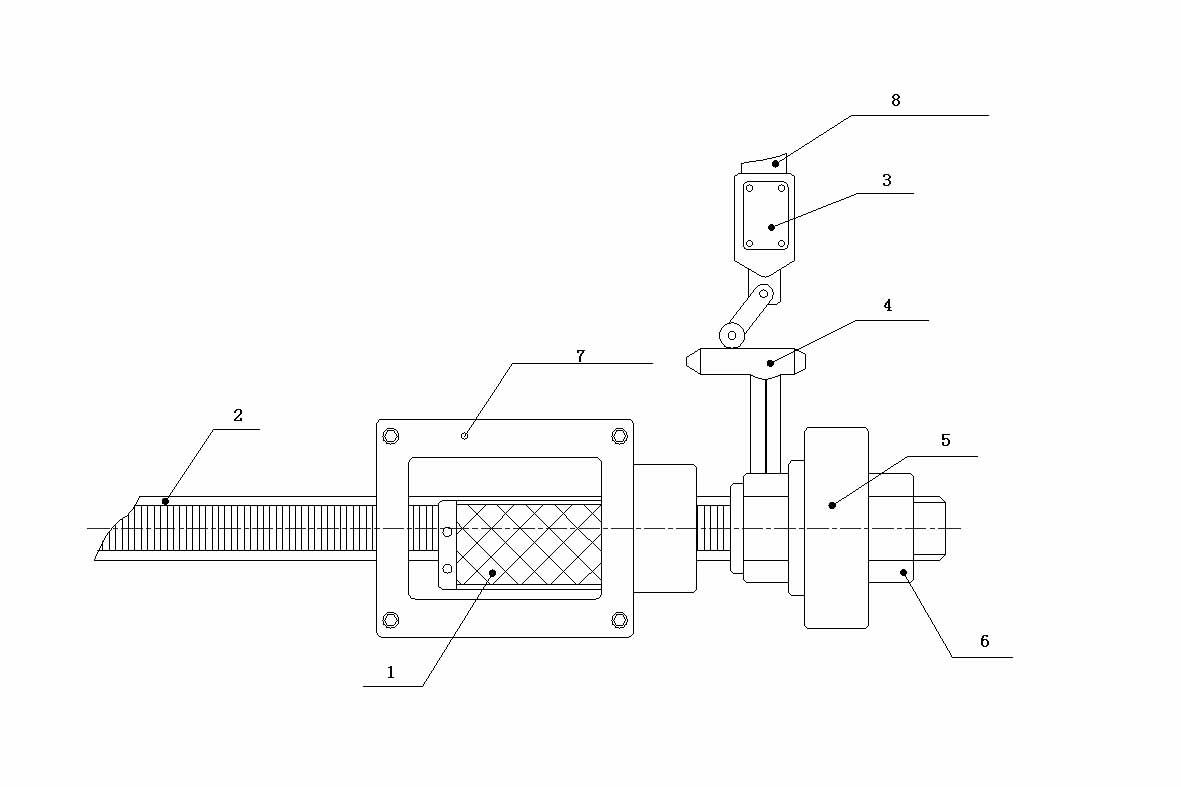

[0010] The new type of die-casting machine, on the basis of ordinary die-casting machines, firstly removes the original travel switch on the injection part, the injection piston 11 of the die-casting machine is connected with the rotary encoder and the grating scale mechanism through the connecting plate 5, and the pull rod of the grating scale 2 The front end and the connecting plate 5 are tightly connected together with a backup nut 6, and a limit stopper 4 and a limit travel switch 3 are fixed at the front end of the pull rod of the grating ruler 2, so as to limit the injection return and start the injection. letter function. The base 8 of the limit travel switch 3 is fixed on the injection frame 10 of the die-casting machine, the support 7 of the rotary encoder 1 is fixed on the injection frame 10 of the die-casting machine, the rotary encoder 1 and the programmable controller of the die-casting machine connect. The model of rotary encoder 1 is XZ-550A, the model of grati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com