An anti-twist device for a crane wire rope

An anti-twist and steel wire rope technology, which is applied in the field of steel wire ropes in the hoisting mechanism of large-lift cranes, can solve the problems that torsional stress cannot be released and affects the service life of steel wire ropes, and achieves the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

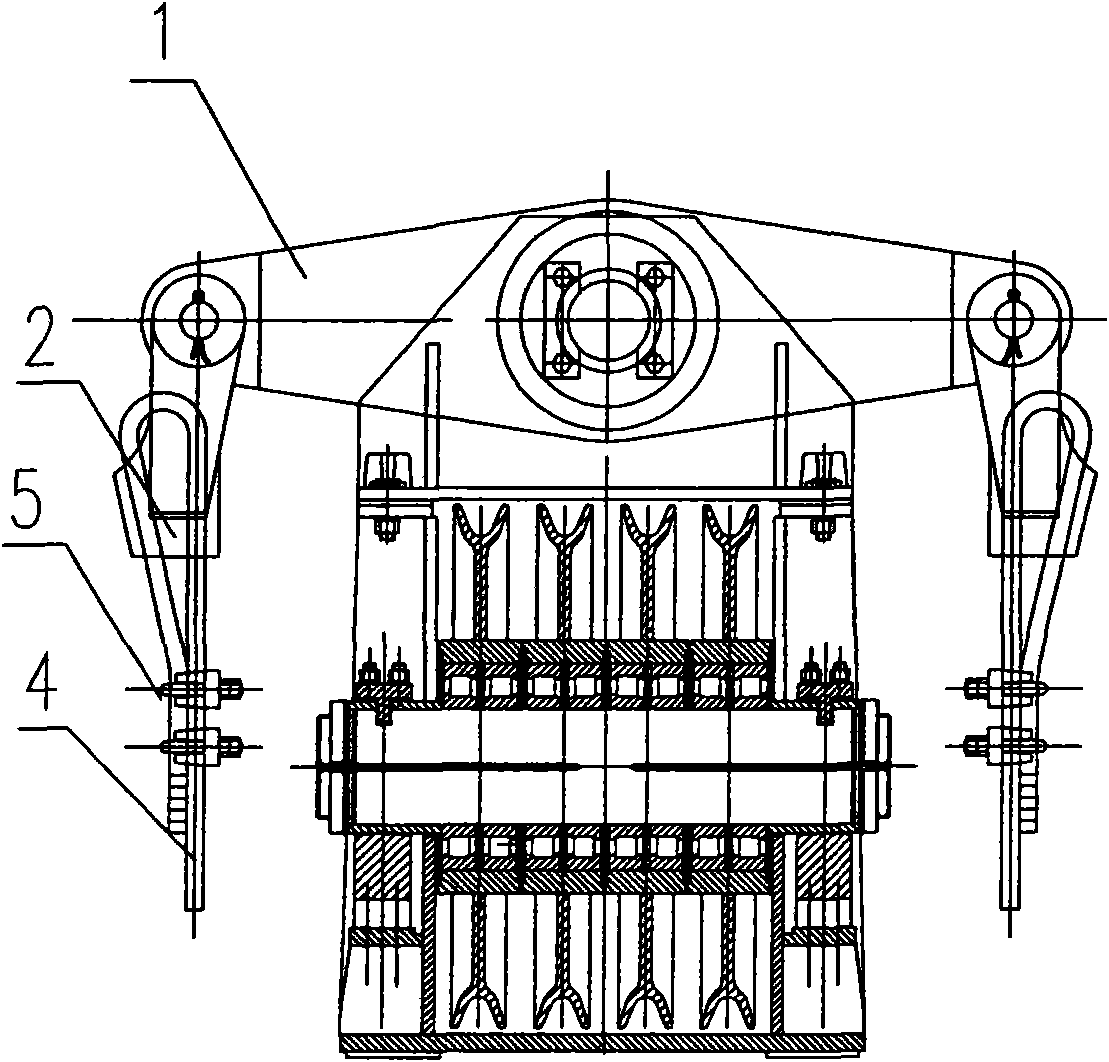

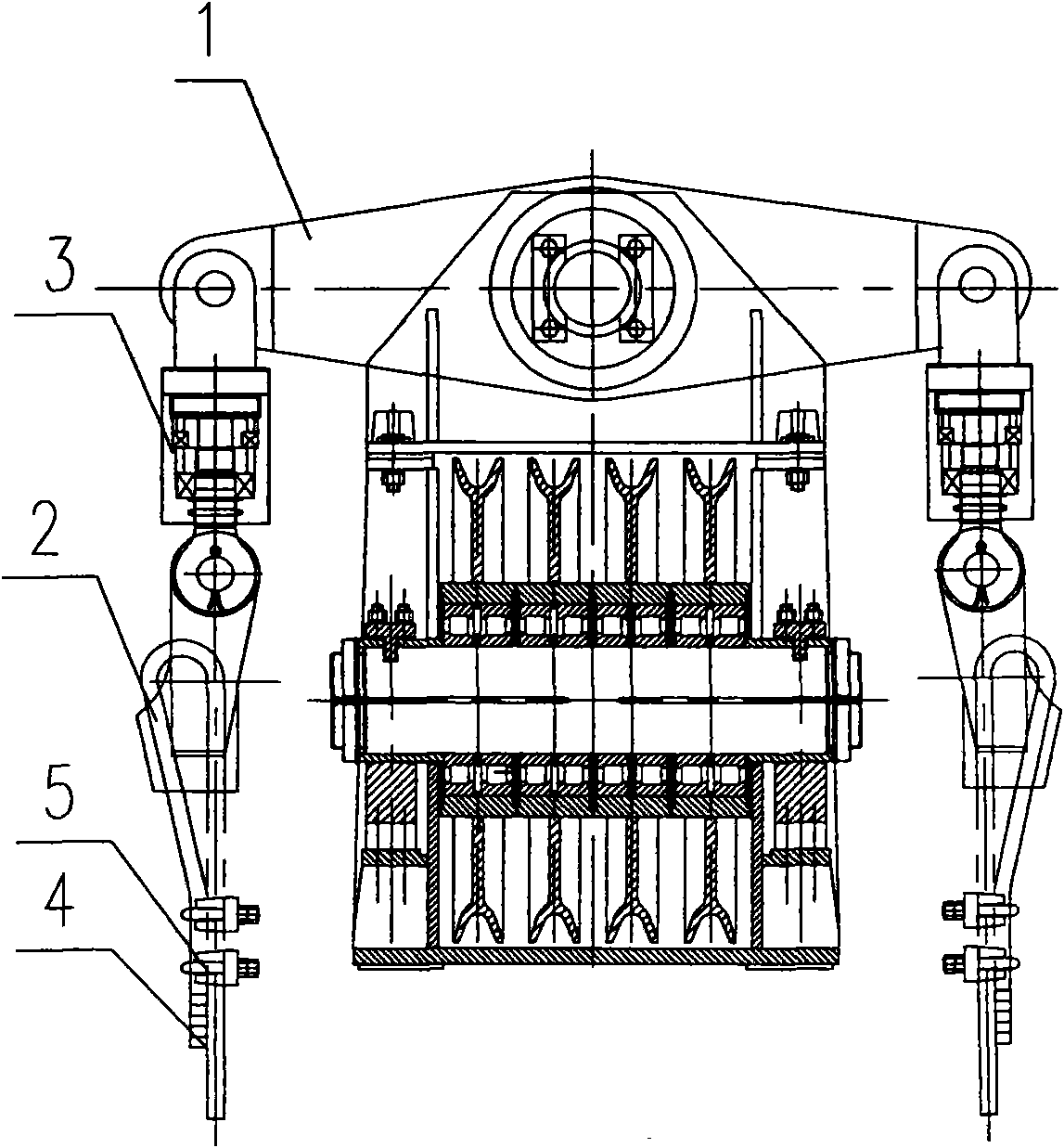

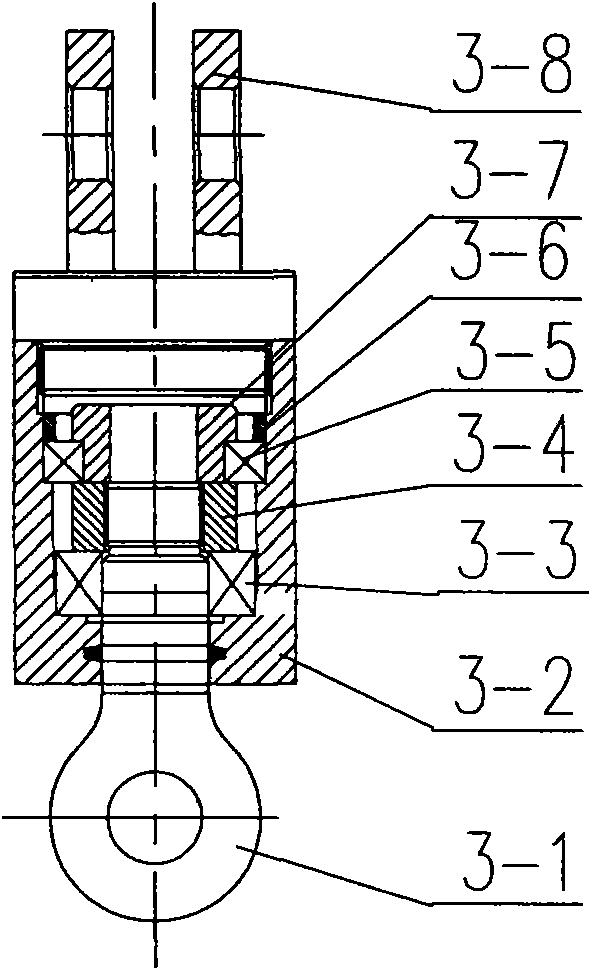

[0014] Such as figure 2 , 3 As shown, one end of the anti-twist device 3 of the two crane wire ropes is respectively hinged to the two ends of the balance arm 1 of the pulley device on the hoisting mechanism of the crane, and the other ends of the two anti-twist devices 3 are respectively hinged to the wedge joint 2, so The wedge-shaped joint 2 and the wire rope 4 are fixedly connected by the wire rope clip 5; the two anti-twist devices 3 are composed of a trunnion 3-1, a housing 3-2, a thrust bearing 3-3, a nut 3-4, a radial Bearing 3-5, inner bushing 3-6, outer bushing 3-7, seat body 3-8; the seat body 3-8 is hinged at the end of the balance arm 1, and the trunnion 3- 1 and the ear hole of the wedge joint 2 are hinged, and the shaft body of the trunnion 3-1 passes through the thrust bearing 3-3, the nut 3-4, the radial bearing 3-5, the inner bushing 3- 6. The outer shaft sleeve 3-7 is installed in the housing 3-2.

[0015] The thrust bearing 3-3 is set on the shaft body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com