A seamlessly connected corner stage board and its manufacturing process

A technology of seamless connection and manufacturing process, applied in the field of stage boards and seamless connection corners, can solve the problems of easily scratching people's hands, many production processes, and unsightly appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

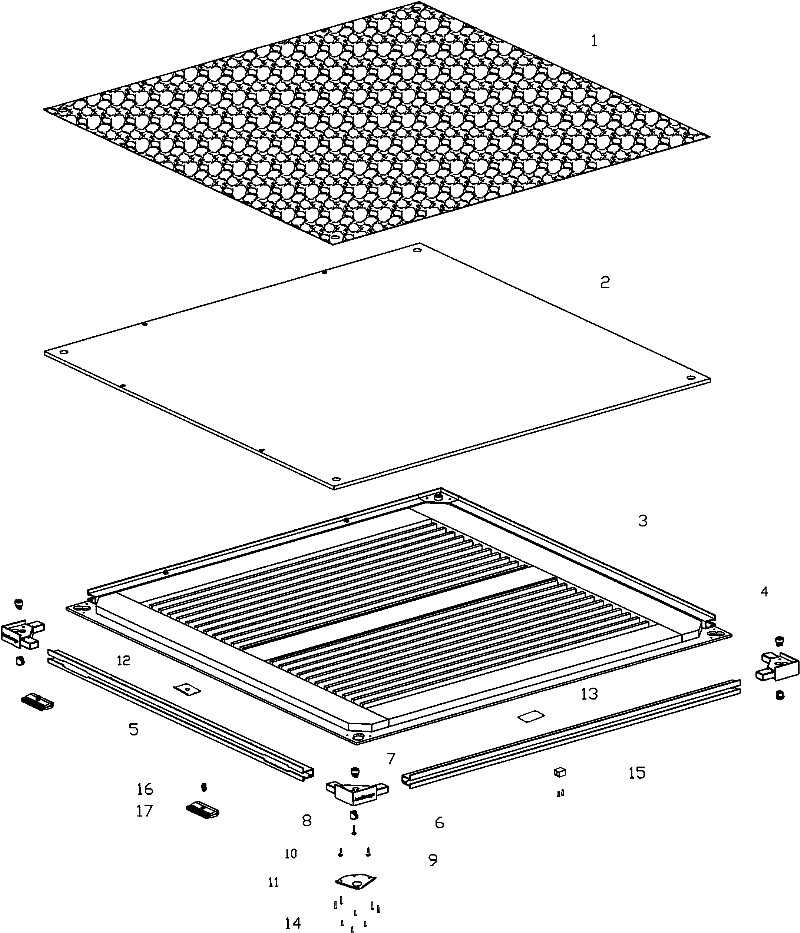

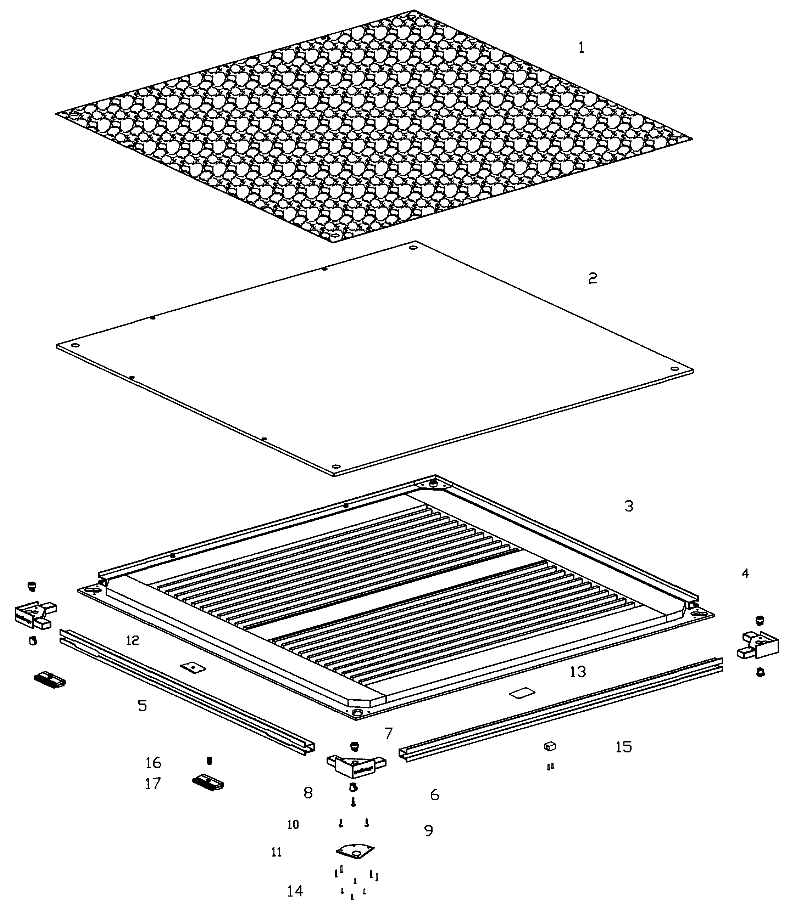

[0021] Such as figure 1 As shown, a stage board includes a spraying surface 1, a panel 2, a bottom plate 4, edge material 5, a seamless connection angle 6, an upper connector 7, a lower connector 8, a large flat machine wire 9, a fixed machine wire 10, Symmetrical gasket 11, side gasket with holes 12, middle gasket without holes 13, pull stud 14, aluminum square tube 15, machine rice 16, split type opener 17. The panel 2 is sandwiched between the sprayed surface 1 and the base plate 4, and the base plate 4 is a honeycomb structure. The upper end of the base plate 4 is provided with a hole edge gasket 12, and the base plate 4 is equipped with an aluminum edge material 5. A seamless corner stage board, comprising a bottom plate 4 and a panel 2, a seamless corner 6 is provided at the upper corner of the stage board, and one end of the seamless corner 6 is inserted into the cavity of the edge material 5, without The other end of the seam connection angle 6 is inserted into anoth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com