Self-calibrating putting-into-type pressure liquid level meter and measuring method thereof

A pressure liquid, submersible technology, used in submersible pressure level gauges, high-precision submersible pressure level gauges, can solve the problems of unstable measurement, unreliable sealing performance, and inability to measure high temperature and large range liquid levels. , to achieve the effect of simple structure, low cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

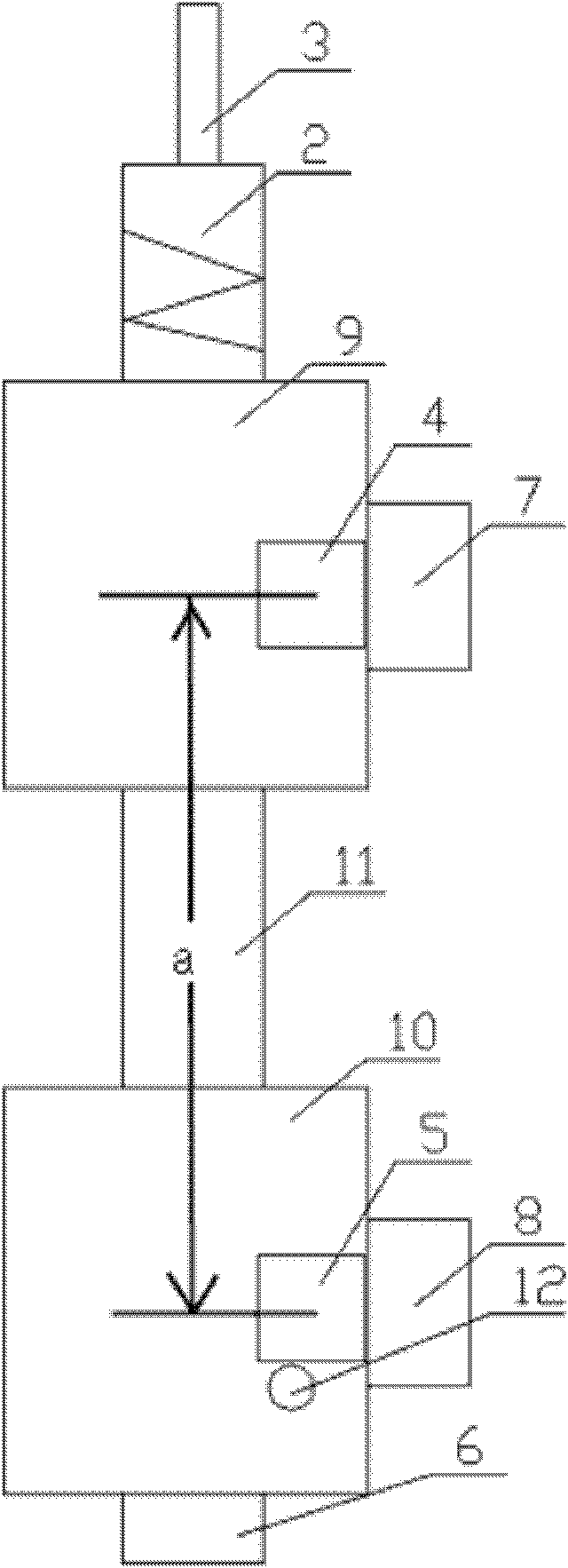

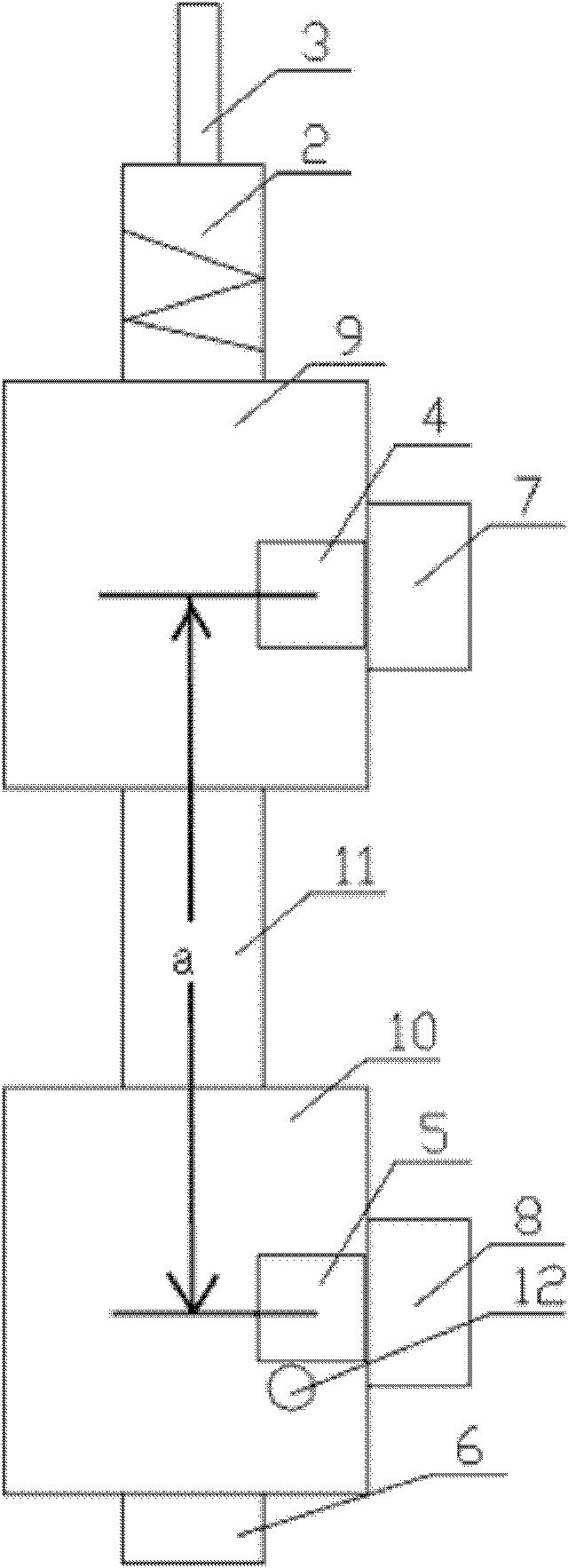

[0034] see figure 1 , a self-calibration input pressure liquid level gauge, including a casing and a cable, a main sensor and a secondary sensor are arranged in the casing, and cables are connected to the primary sensor and the secondary sensor;

[0035] The main sensor is fixedly arranged under the auxiliary sensor, and the vertical distance between the main sensor and the auxiliary sensor is fixed as a.

[0036] The bottom of the casing is provided with a base.

[0037] A main pressure introduction hole is provided on the surface of the housing corresponding to the main sensor; an auxiliary pressure introduction hole is provided on the surface of the housing corresponding to the auxiliary sensor.

[0038] A corrugated hose is connected to the top of the housing, and the corrugated hose communicates with the housing.

[0039] The shell is composed of a main shell, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com