Engine exhaust temperature inspection system based on ModbusTCP/IP

A technology of exhaust temperature and inspection system, which is applied to thermometers, control/regulation systems, thermometers, etc. that use electric/magnetic components that are directly sensitive to heat, and can solve problems such as low transmission rate, backward networking mode, and short transmission distance and other issues, to achieve the effect of high data transmission rate, easy network opening, and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

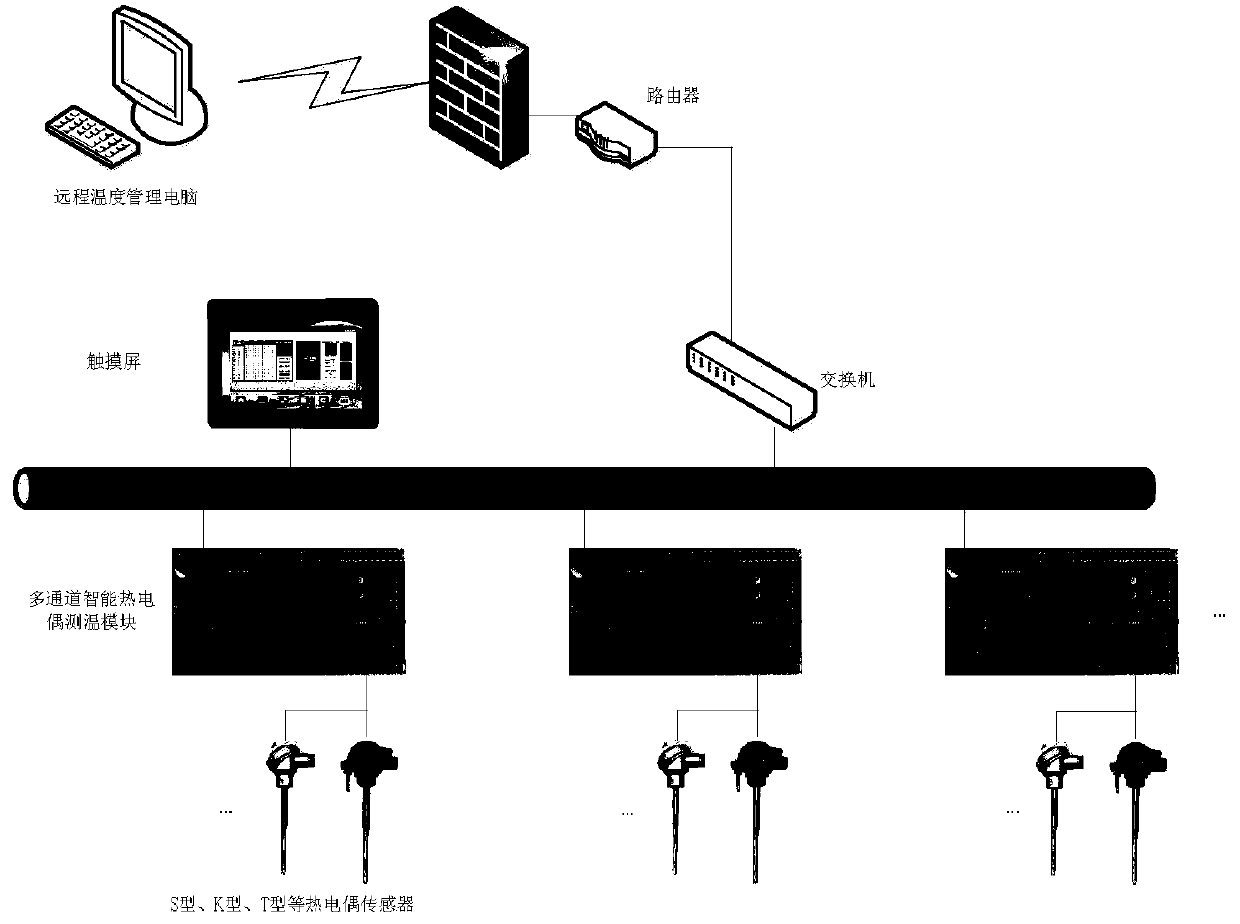

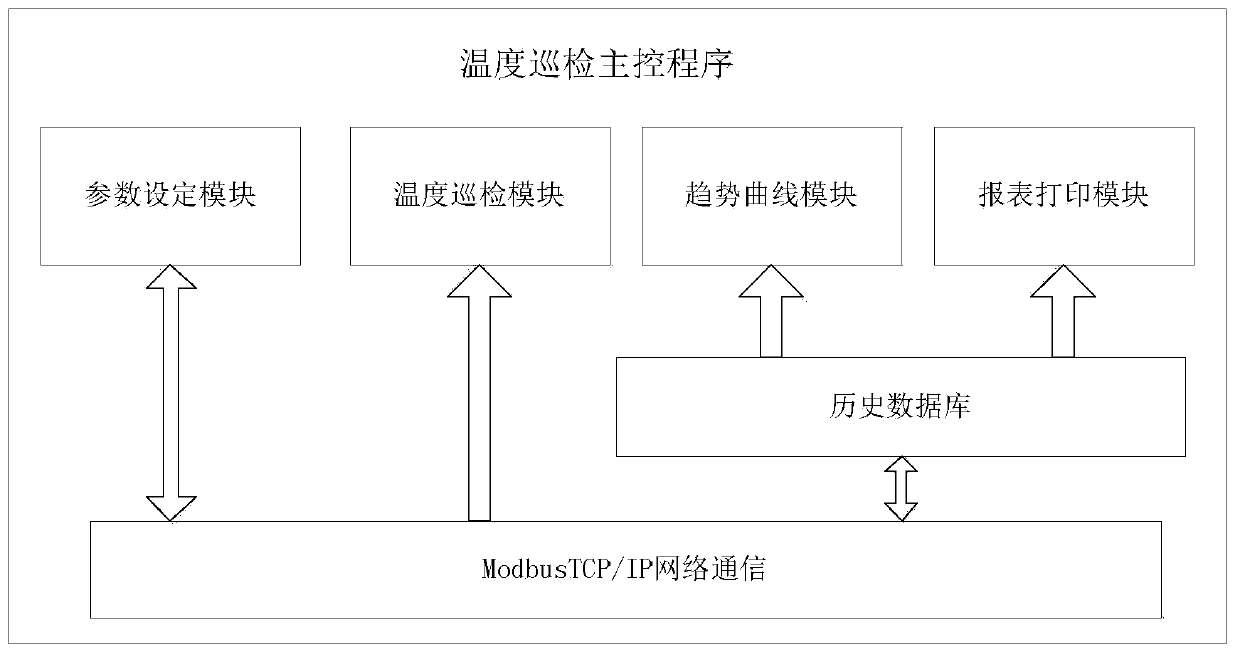

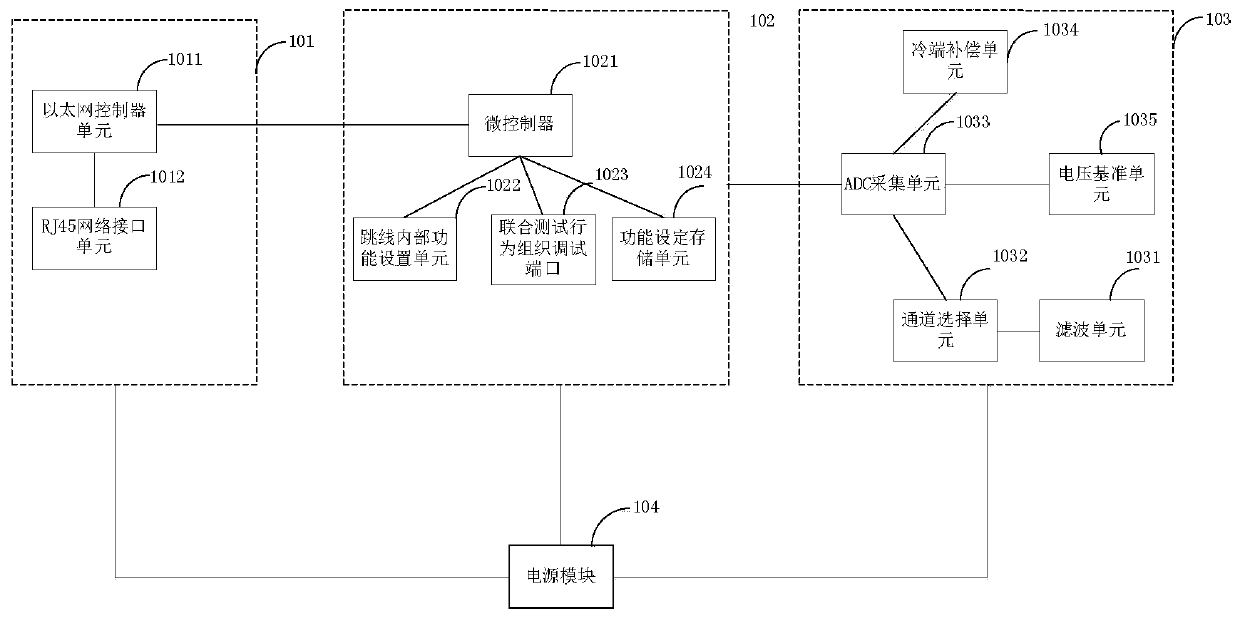

[0030] Such as Figure 1 to Figure 3 As shown, the temperature inspection system described in this embodiment includes a lower multi-channel thermocouple intelligent temperature measurement module and an upper PC or touch screen equipped with a temperature inspection master control program. The temperature measurement module is mainly composed of microcontroller circuit, thermocouple temperature measurement circuit, Ethernet communication circuit, power supply circuit, function setting and storage circuit;

[0031] In this example, if figure 1As shown, the lower multi-channel thermocouple intelligent temperature measurement module and the upper PC or touch screen equipped with the temperature master control program are used as network nodes to form a star-shaped industrial Ethernet network through switches and routers. Directly connect the positive and negative terminals of the thermocouple input signal to the intelligent temperature measurement module through the terminal bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com