Safety chain protection mechanism and method of vertical impact test bench

A technology of impact test and safety interlocking, which is applied in the field of mechanical environment test, can solve problems such as pins sinking into the work surface, injuring the operator's personal safety, and damaging the work surface, etc., so as to improve safety performance, eliminate safety hazards, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

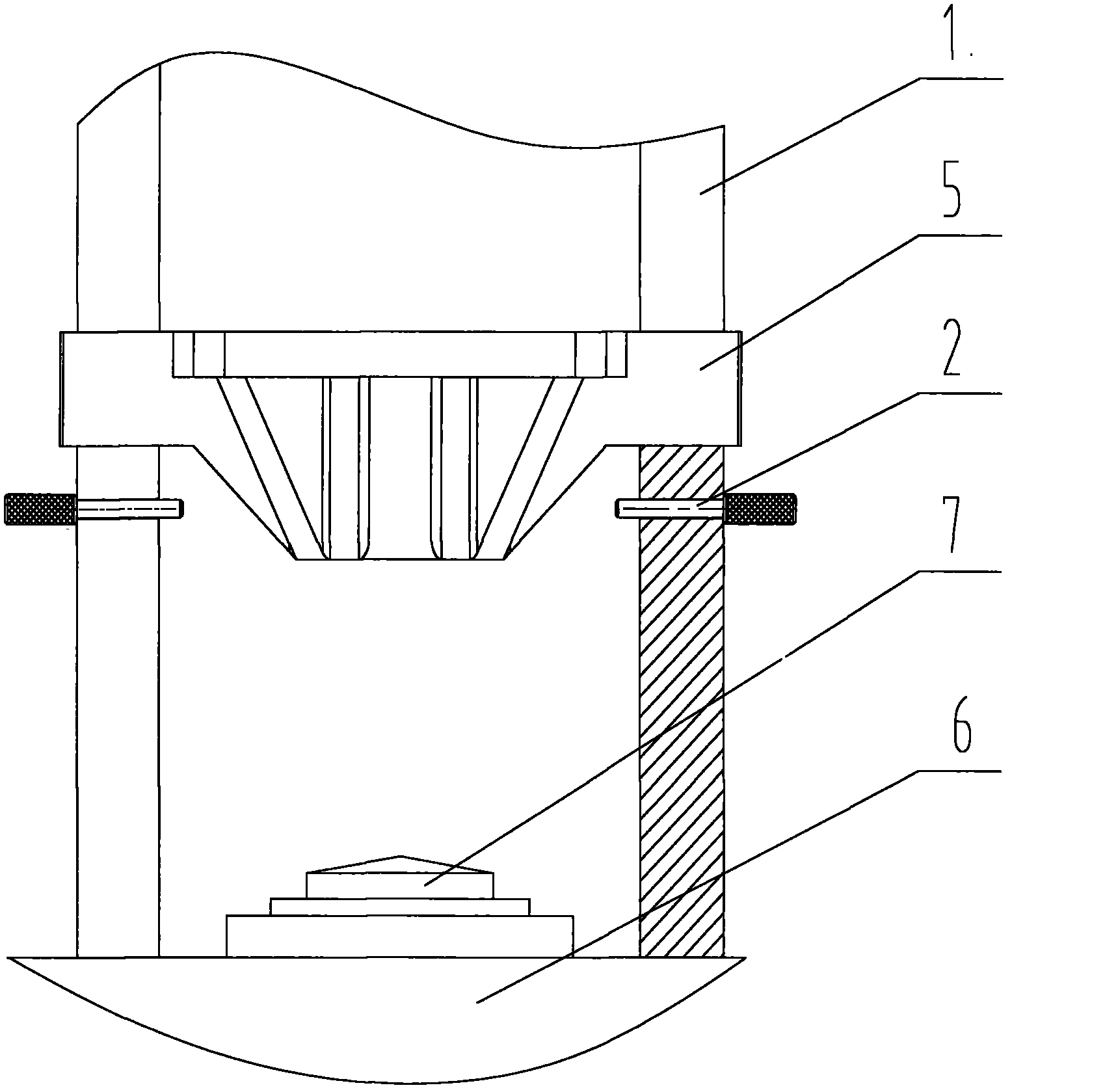

[0026] Example 1 see figure 2 As shown, in this embodiment, a hole is opened on the safety plug 2, and the switching device 3 is placed in the hole of the safety plug 2. During the test, when replacing the waveform generator, raise the worktable 5 to a set height, so that the worktable 5 is a certain distance above the pin hole on the guide post 1, and after starting the brake, insert the safety pin 2, and the switch device 3 obtains the signal Feedback to the control system, so that the control system sends an action command to be controlled, and the equipment enters a locked state, so that the work surface cannot be lowered; after the safety plug 2 is taken out, the control system can issue an action command, and the equipment is unlocked.

Embodiment 2

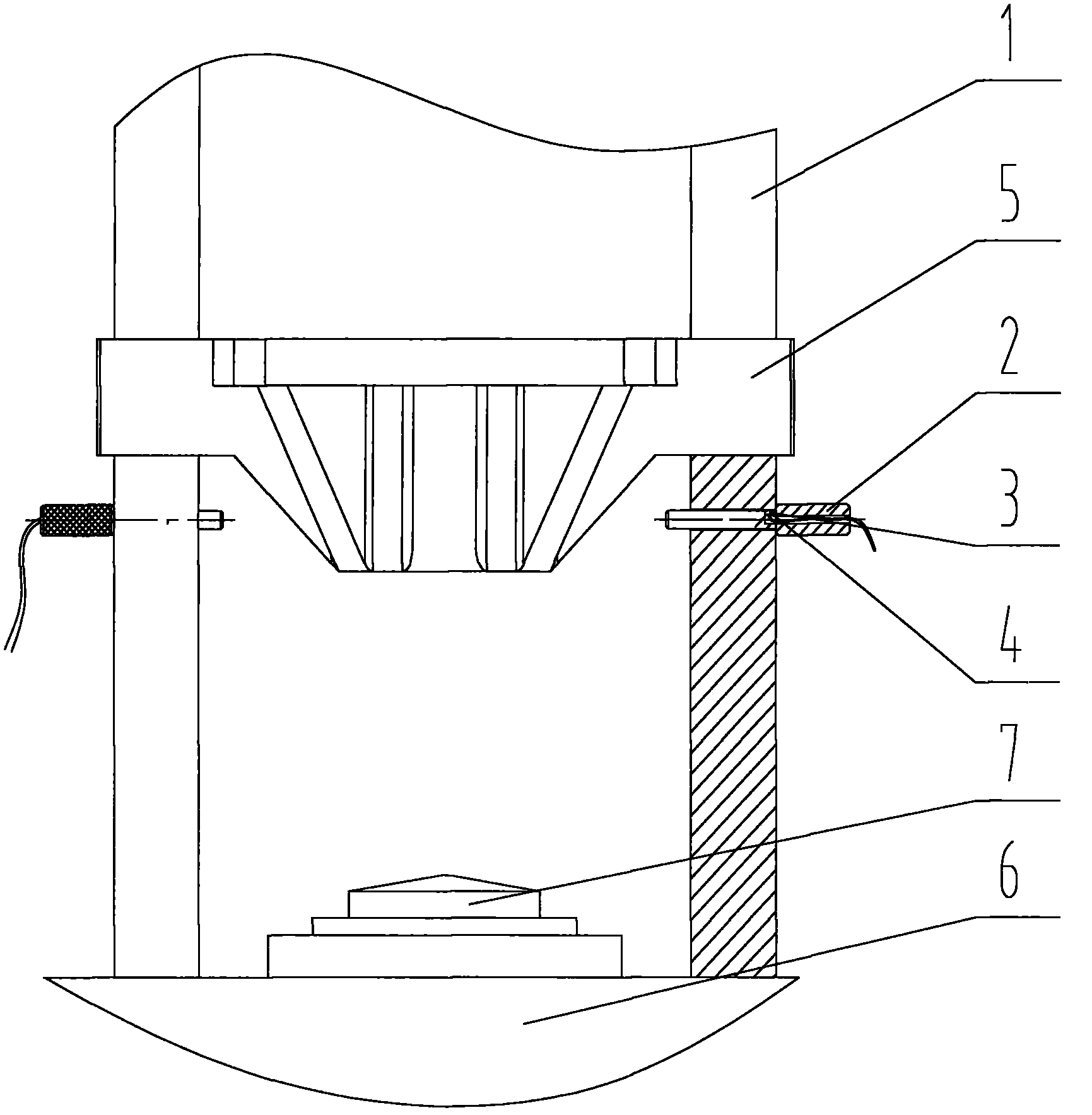

[0027] Example 2 see image 3 As shown, in this embodiment, the switch fixing base 4 is fixed on the base 6 , and the switch 2 is installed on the switch fixing base 4 and placed on the side of the safety bolt 2 . During the test, when replacing the waveform generator, raise the worktable 5 to a set height, so that the worktable 5 is a certain distance above the pin hole on the guide post 1, and after starting the brake, insert the safety pin 2, and the switch device 3 obtains the signal Feedback to the control system, so that the control system sends an action command to be controlled, and the equipment enters a locked state, so that the work surface cannot be lowered; after the safety plug 2 is taken out, the control system can issue an action command, and the equipment is unlocked.

Embodiment 3

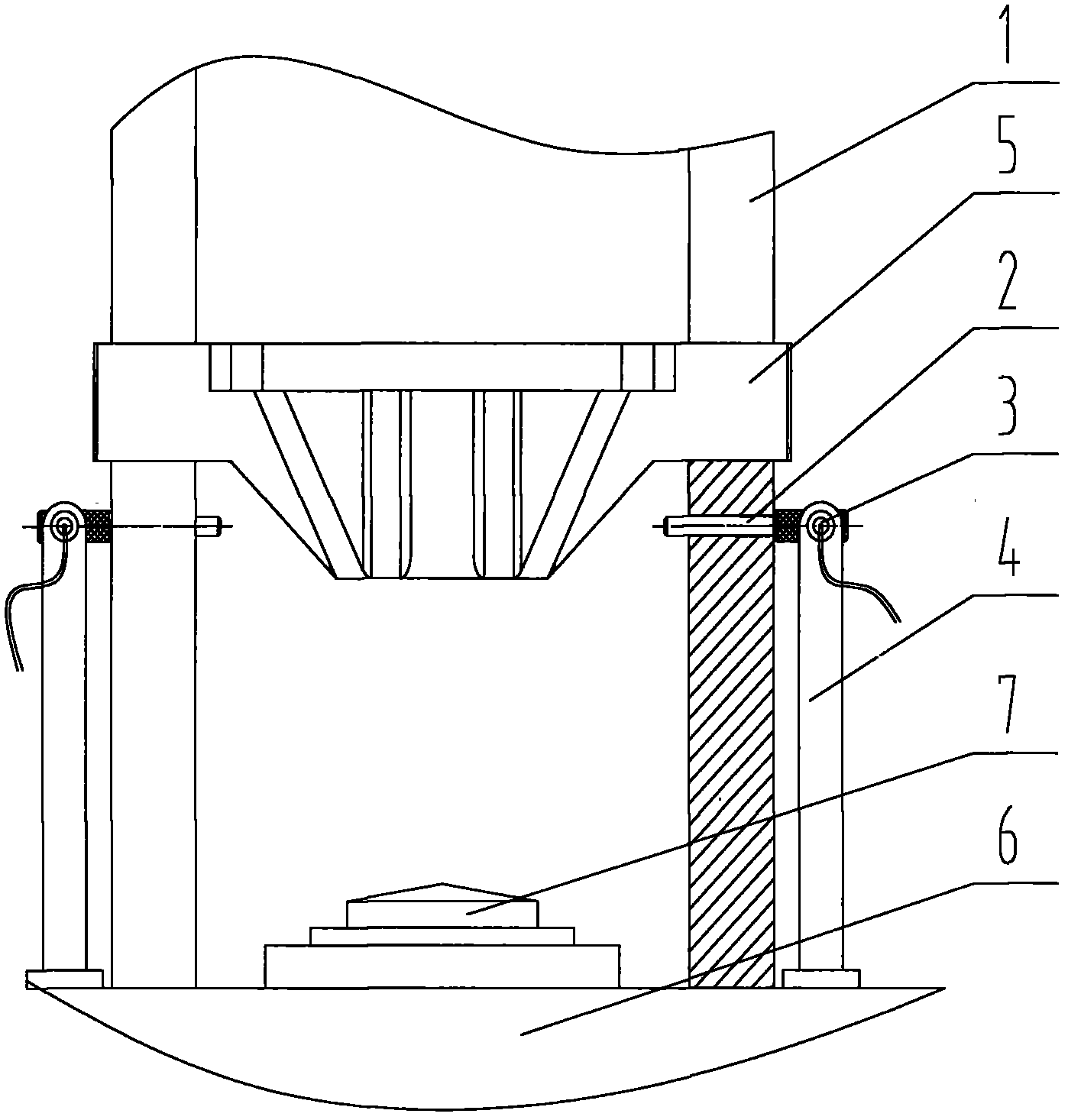

[0028] Embodiment 3 see Figure 4 As shown, in this embodiment, the switch fixing base 4 is fixed on the work surface 5 , and the switch device 3 is installed on the switch fixing base 4 and placed above the safety plug 2 . During the test, when replacing the waveform generator, raise the worktable 5 to a set height, so that the worktable 5 is a certain distance above the pin hole on the guide post 1, and after starting the brake, insert the safety pin 2, and the switch device 3 obtains the signal Feedback to the control system, so that the control system sends an action command to be controlled, and the equipment enters a locked state, so that the work surface cannot be lowered; after the safety plug 2 is taken out, the control system can issue an action command, and the equipment is unlocked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com