35-220kv line maintenance operation frame

A technology for line maintenance and operation racks, applied in the field of operation racks, can solve the problems of difficult to control the operation position, reduce the safety factor, low safety factor, etc., and achieve the effects of improving safety and work efficiency, improving safety factor, and increasing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

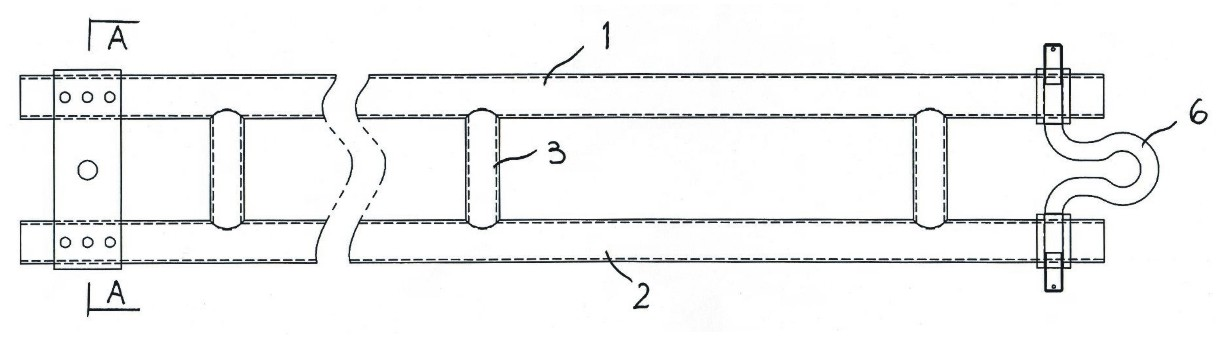

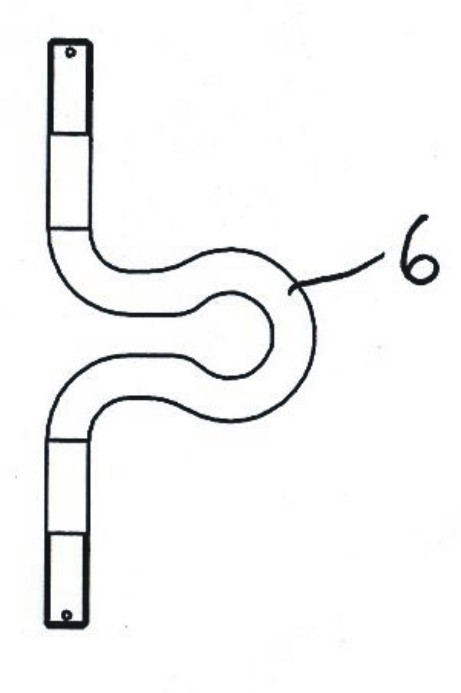

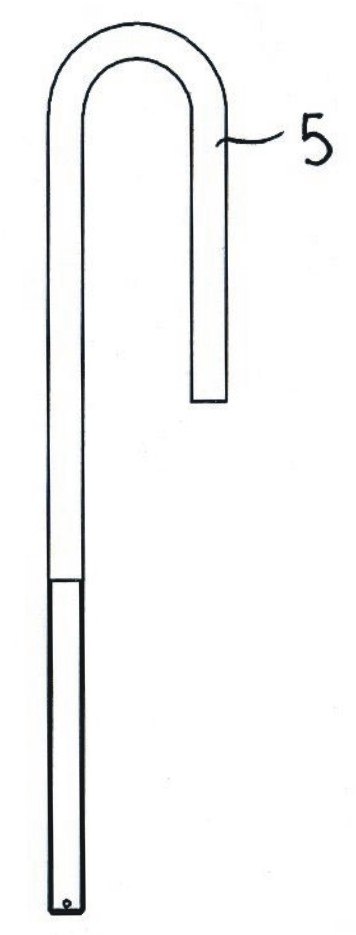

[0015] figure 1 It shows that this 35-220kV line maintenance operation frame: a number of longitudinal tubes 3 are uniformly fixed between two aluminum alloy tubes 1 and 2 arranged horizontally, and the tube sleeve 4 is fixed to the left end of the two aluminum alloy tubes by bolts. The hook 5 is fixed on the pipe sleeve 4 by bolts, and the hanging ring 6 is hinged on the right ends of the two aluminum alloy pipes. The hanging ring 6 is hinged on the right end of the two aluminum alloy tubes 1, 2 via a split pin (see figure 2 , image 3 , Figure 4 ). A hole is made on the aluminum alloy pipe, and the hanging ring is penetrated from the hole on the aluminum alloy pipe, and a cotter pin is used to fix the cotter pin hole on the outer end of the hanging ring. The hanging ring can also adopt other existing articulation methods, for example, a rotating shaft is erected on two aluminum alloy tubes, and the hanging ring is fixed on the rotating shaft.

[0016] The operating rack of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com