Motor stator structure for flux weakening speed regulation

A stator structure, weak field speed regulation technology, applied in the direction of the shape/style/structure of the magnetic circuit, the static parts of the magnetic circuit, etc., can solve the problem of difficult weak field control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

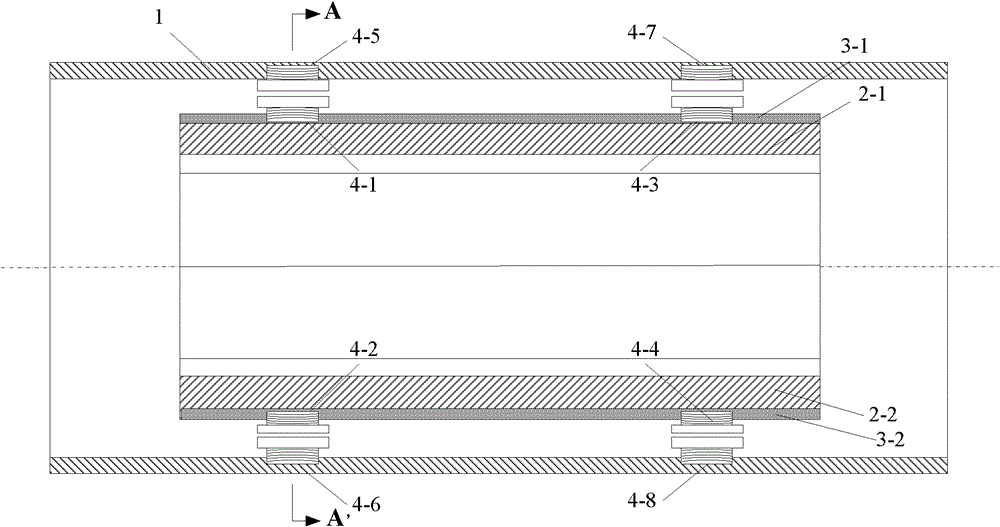

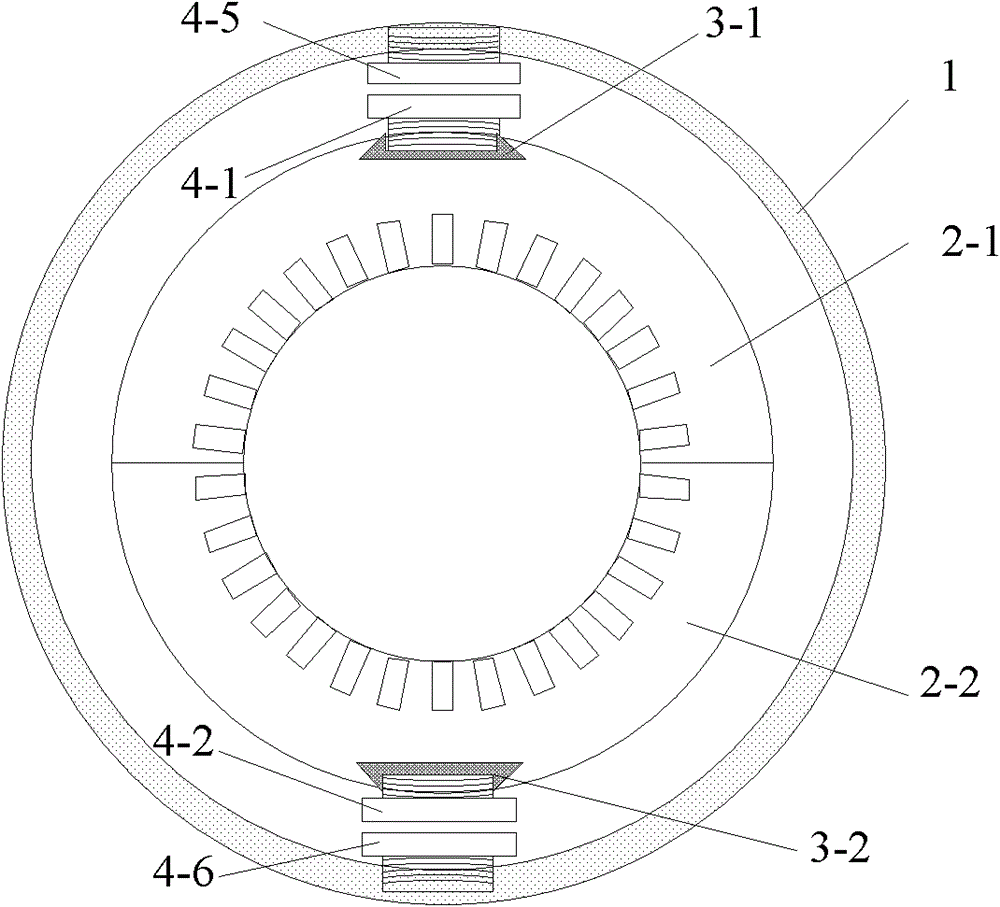

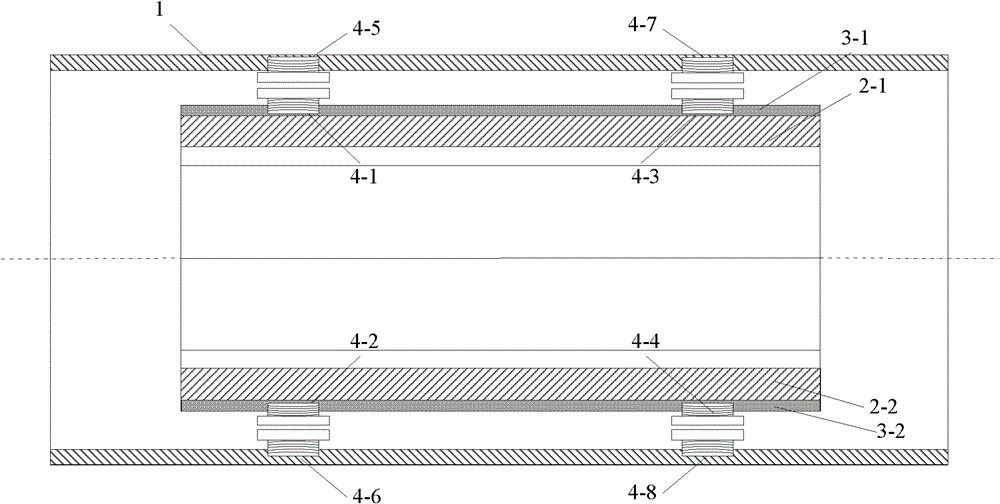

[0033] A stator structure for motor field-weakening speed regulation, the stator structure includes a casing 1, a stator core, such as figure 1 , 2 shown. The stator core includes an upper split stator core 2-1 and a lower split stator core 2-2.

[0034] A dovetail groove is axially arranged on the top of the upper split stator core 2-1, and a first magnetic isolation plate 3-1 is installed in the dovetail groove, and a first magnetic isolation plate 3-1 is installed in the axial direction in the first magnetic isolation plate 3-1. Iron 4-1 and the third electromagnet 4-3.

[0035] A dovetail slot is axially arranged at the bottom of the lower split stator core 2-2, a second magnetic isolation plate 3-2 is installed in the dovetail slot, and a second electromagnet is installed axially in the second magnetic isolation plate 3-2 4-2 and the fourth electromagnet 4-4.

[0036] On the position corresponding to the first electromagnet 4-1 and the third electromagnet 4-3 installe...

Embodiment approach 2

[0046] The difference between Embodiment 2 and Embodiment 1:

[0047] There are first and second tension springs 5-1, 5-2 and third and fourth tension springs 5-3 and 5-4 between the casing 1 and the upper split stator core 2-1; The first and second pressure springs 6-1 and 6-2 and the third and fourth pressure springs 6-3 and 6-4 are arranged between the casing 1 and the lower split stator core 2-2.

[0048] The first and second tension springs 5-1, 5-2 and the first and second pressure springs 6-1, 6-2 are in the same axial cross-section and evenly distributed along the circumference.

[0049] The third and fourth tension springs 5-3 and 5-4 and the third and fourth pressure springs 6-3 and 6-4 are in the same axial cross-section and evenly distributed along the circumference. Such as image 3 , 4 , 5, and 6.

Embodiment approach 3

[0051] The difference between Embodiment 3 and Embodiment 1:

[0052] Described first electromagnet 4-1, the second electromagnet 4-2 and the 3rd electromagnet 4-3, the 4th electromagnet 4-4 respectively use the first permanent magnet 7-1, the second permanent magnet 7-2 , the third permanent magnet 7-3 and the fourth permanent magnet 7-4 instead, as Figure 7 , 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com