A Synchronous Motor Excitation System

A synchronous motor and excitation system technology, applied in the field of excitation system, can solve the problems of insufficient excitation of the motor, insufficient output torque of the motor, and excessive excitation voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

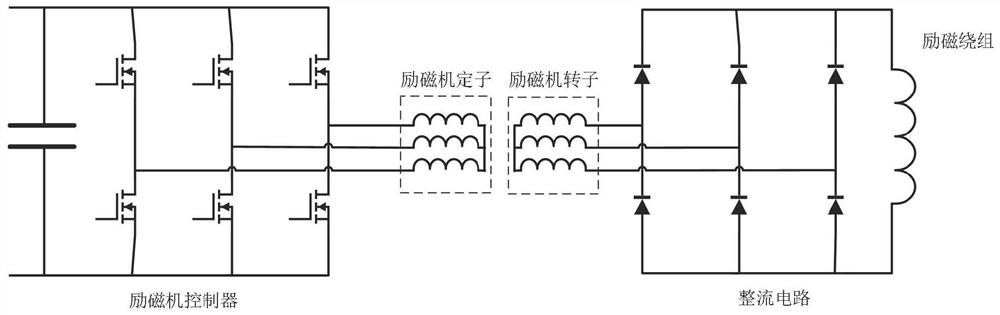

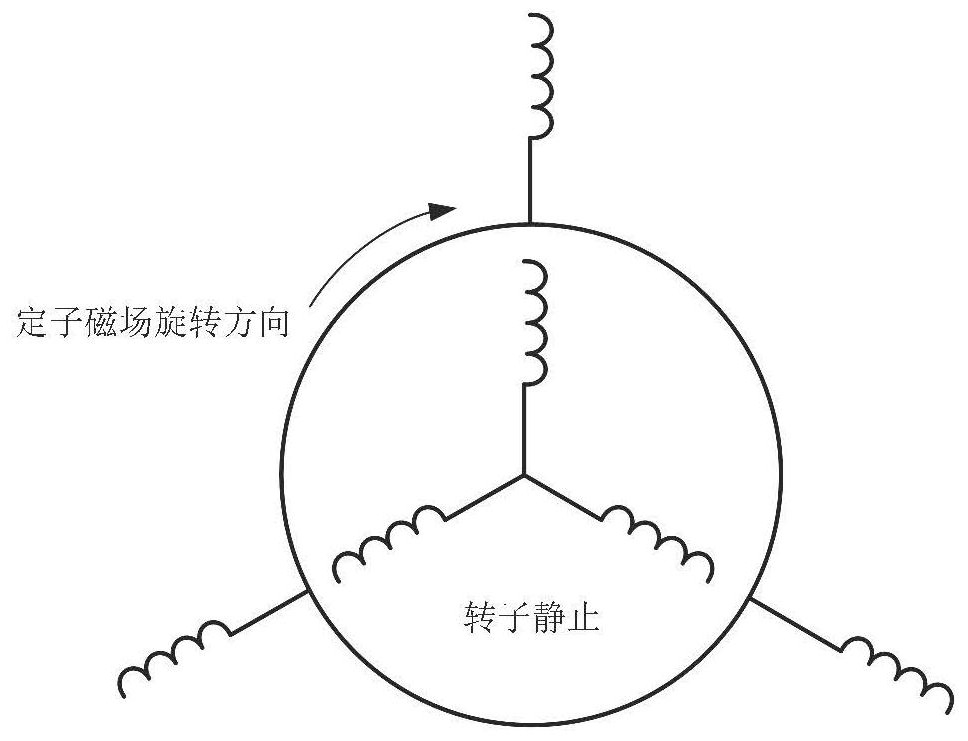

[0022] Combine below Figures 1 to 6 Description of this embodiment, a synchronous motor excitation system, including a controller and an exciter, the exciter and the synchronous motor are coaxially connected, and the controller adjusts the three-phase voltage input to the exciter; The frequency and amplitude of the excitation voltage can be flexibly controlled through the controller, which can be adapted to the rotor of the synchronous motor to the greatest extent, so that the synchronous motor can be excited in the full speed range, and the synchronous motor can be guaranteed at low speeds. Torque output, and realize the field weakening control of the synchronous motor rotor in the high speed section.

specific Embodiment approach 2

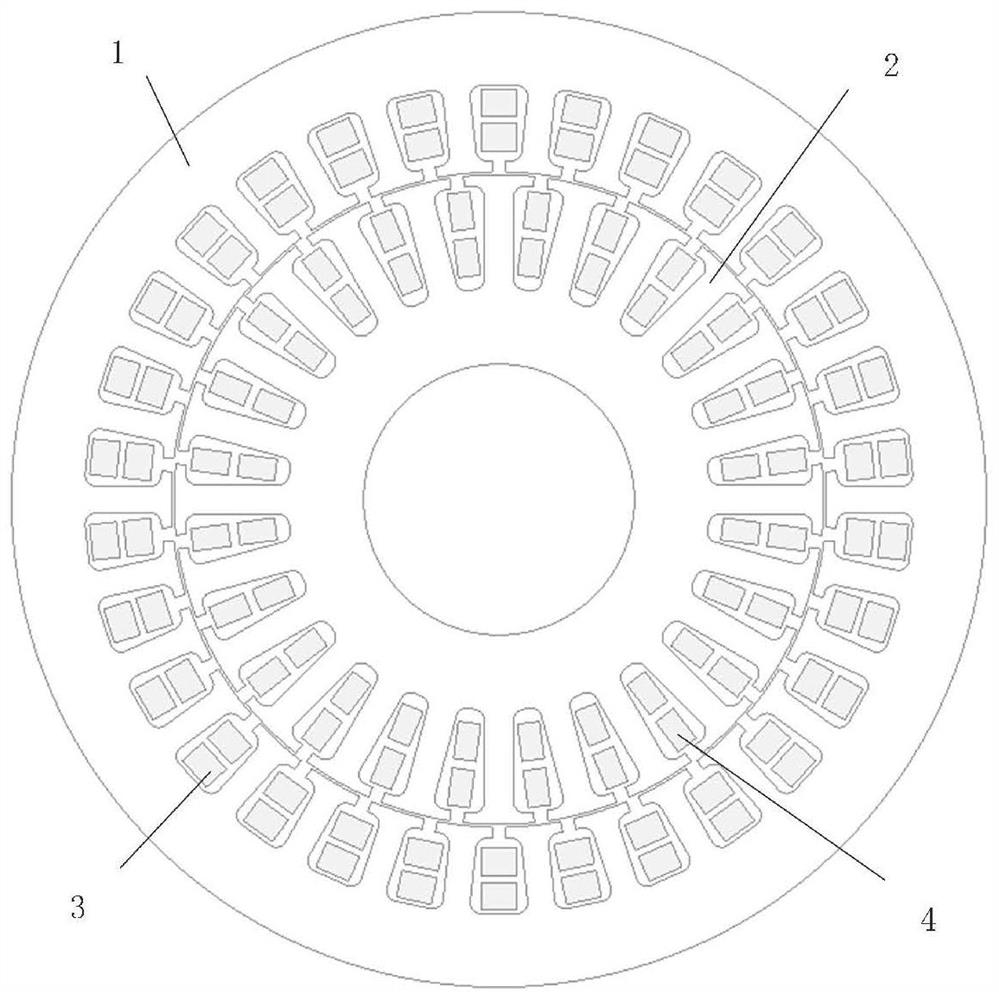

[0023] Combine below Figures 1 to 6 Describe this embodiment, this embodiment will further explain the first embodiment, the exciter includes the exciter stator core 1, the exciter rotor core 2, the exciter stator winding 3 and the exciter rotor winding 4, the exciter stator iron core The exciter stator winding 3 is arranged on the core 1, the exciter rotor winding 4 is arranged on the exciter rotor iron core 2, the exciter rotor iron core 2 and the synchronous motor are connected coaxially through the shaft 11, the exciter stator winding 3 and the exciter Air gaps are provided between the rotor windings 4 .

specific Embodiment approach 3

[0024] Combine below Figures 1 to 6 This embodiment will be described. This embodiment will further describe the second embodiment. The stator winding 3 of the exciter is a symmetrical three-phase excitation winding, and the three-phase voltage is passed into the stator winding 3 of the exciter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com