A lift and its control system

A technology of lifts and lifting frames, applied in the direction of lifting frames, lifting devices, etc., can solve problems such as lift vibration, inability to decelerate smoothly, and unstable motor speed, so as to achieve stable operation, ensure stability, and meet the needs of production beats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

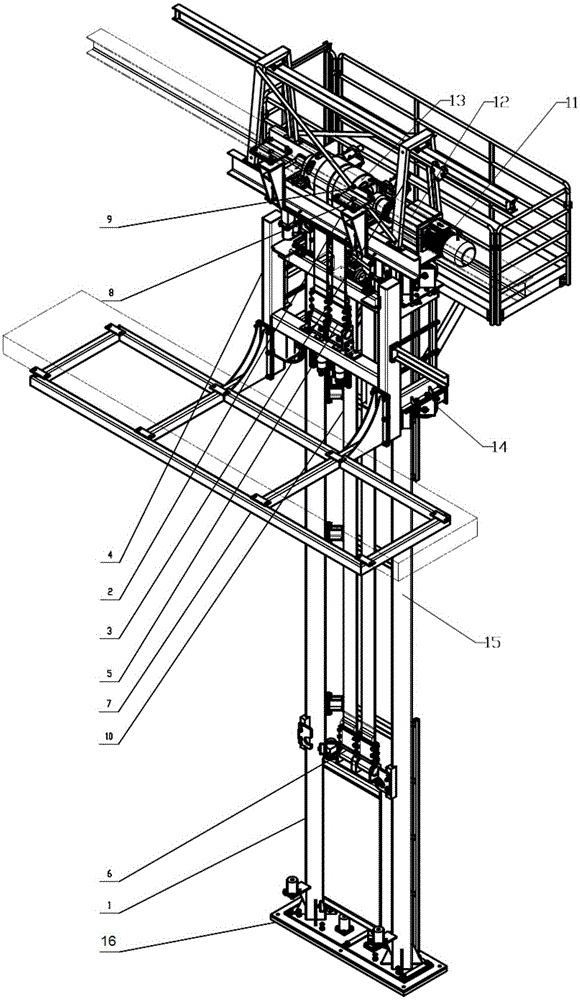

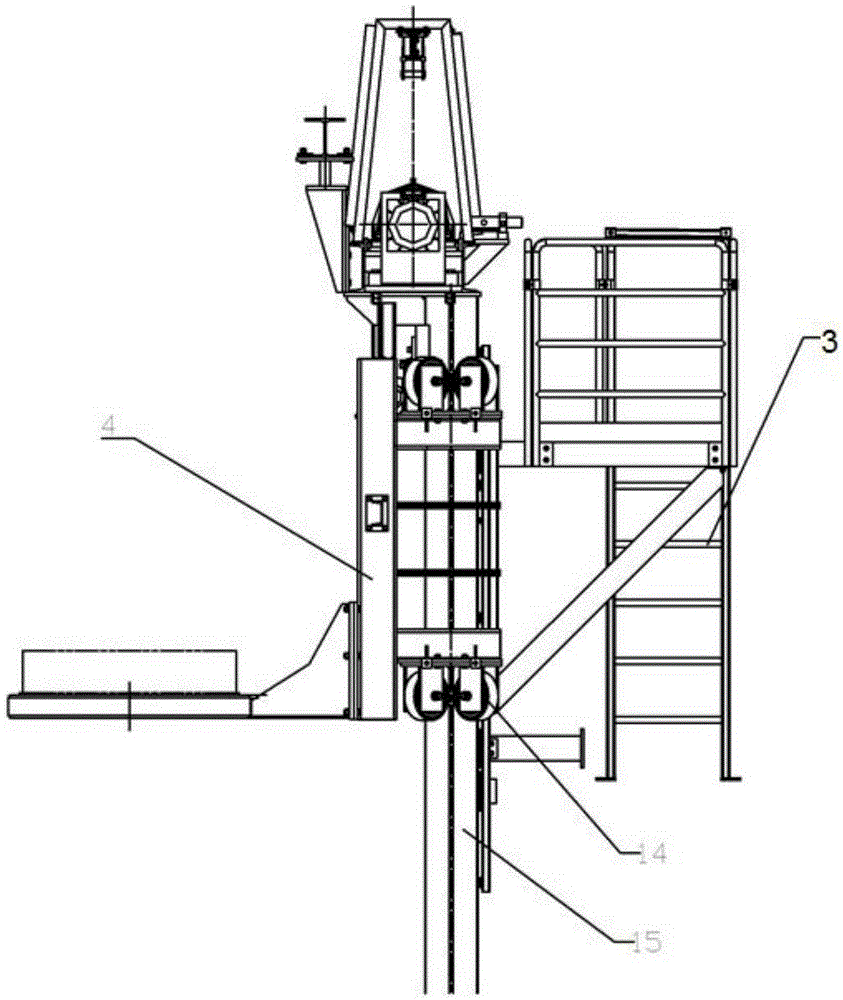

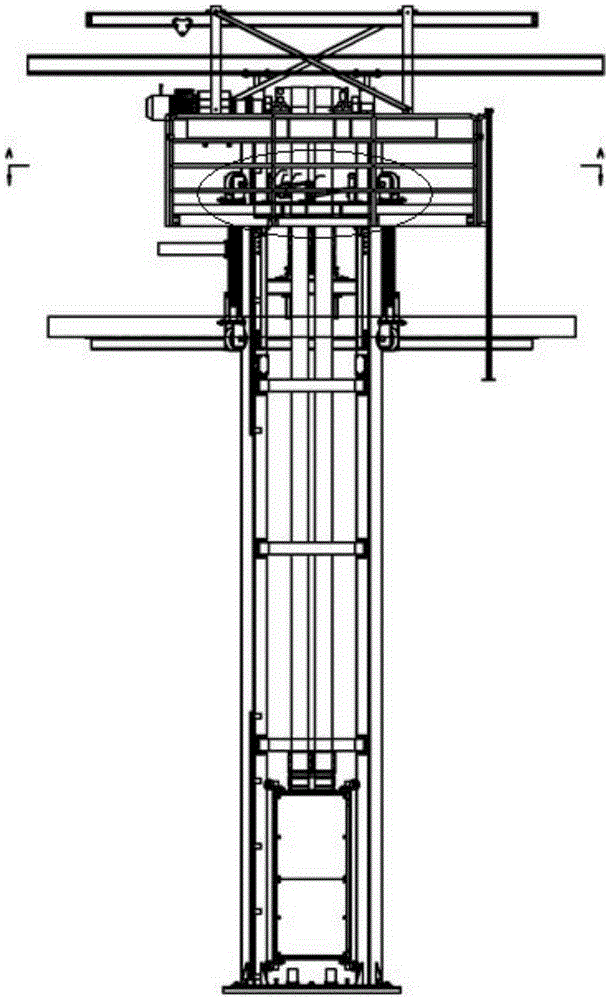

[0034] Figure 1~3 It is a structural schematic diagram of an elevator of the present invention, including a frame bottom plate 16, on which an elevator frame 1 is arranged, and a lifting frame 4 that can move up and down on the elevator frame 1, and an elevator drive 2 is arranged on the top of the elevator frame 1, The elevator drive 2 includes a belt 10, a drive motor 11 connected in sequence, a reducer 12 and a roller 13, and the roller 13 is frictionally engaged with the belt 10;

[0035] One end of the belt 10 is fixedly connected to the lifting frame 4, and the other end is fixedly connected to the counterweight frame 6;

[0036] The lifting frame 4 is a cuboid structure, including a square bottom surface surrounded by four steel pipes, a square top surface surrounded by four steel pipes, and four pillars connecting and supporting the top surface and the bottom surface;

[0037] Lift frame 1 comprises two square columns 15;

[0038] The upper part of the top surface a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com