Auxiliary rotating mechanism for large tubular bus welding

A technology for rotating devices and pipe nuts, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve problems affecting welding quality, reduce welding efficiency, and increase staff fatigue, so as to improve welding quality and welding Efficiency, ensuring balance and stability, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

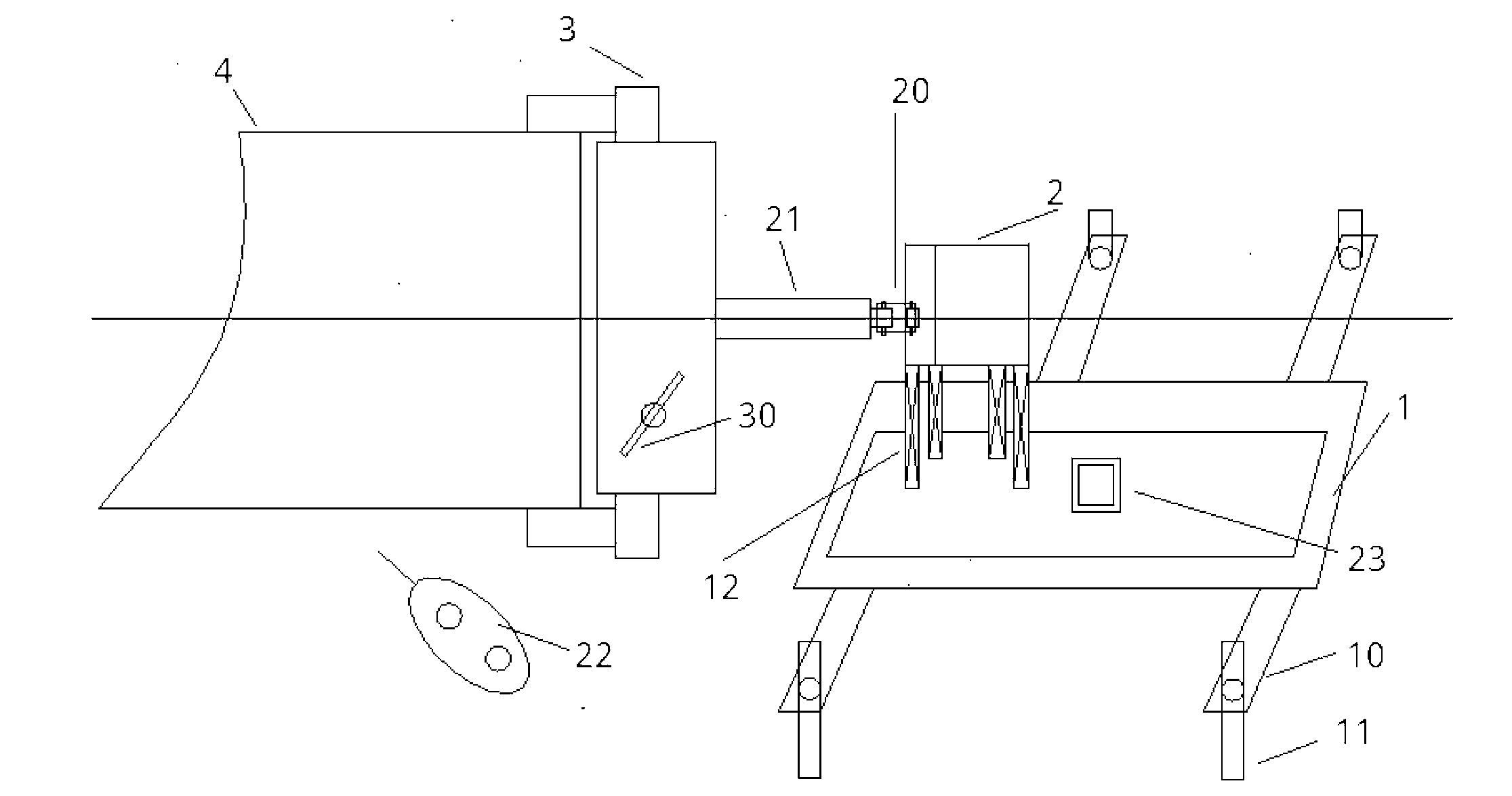

[0014] like figure 1 As shown, it is an embodiment of the large-scale pipe nut welding auxiliary rotating device of the present invention, and the pipe female welding auxiliary rotating device includes a table 1 arranged horizontally. The table 1 is installed on two parallel elongated telescopic blocks 10, and the telescopic blocks are provided with vertically connected strip grooves along the length direction, and the table 1 is fixed to the table 1 by bolts and strip grooves. Both ends of the telescopic block 10 are threadedly connected with an adjustment screw 11, the top of the adjustment screw is provided with an adjustment dial, and the bottom end of the adjustment screw is provided with a base.

[0015] Four automatic balance adjustment rods 12 are vertically arranged on the platform 1, and the four automatic balance adjustment rods 12 are distributed in a rectangular shape. Springs are sleeved on the automatic balance adjustment rods 12, and the top of the automatic ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com