Automatic pulping machine

A refiner and automatic technology, applied in cocoa, grain processing, food science, etc., can solve the problems of difficult pressure adjustment, health hazards to consumers, deterioration, etc., and achieve the effect of light structure and various control operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

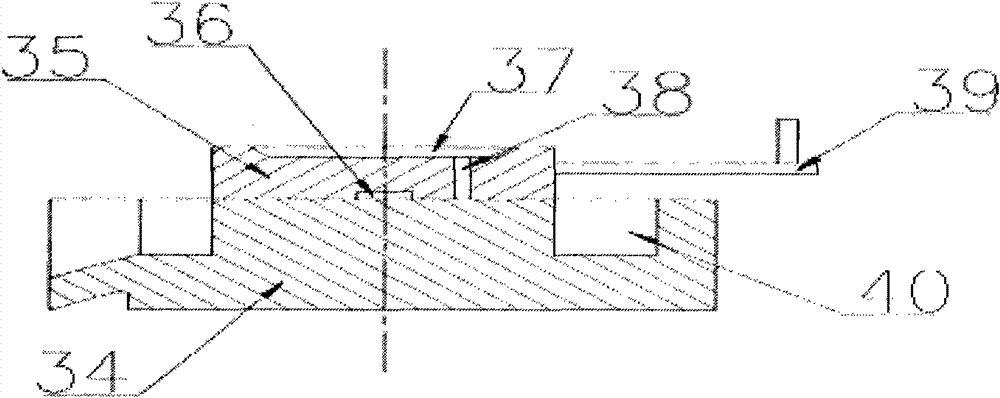

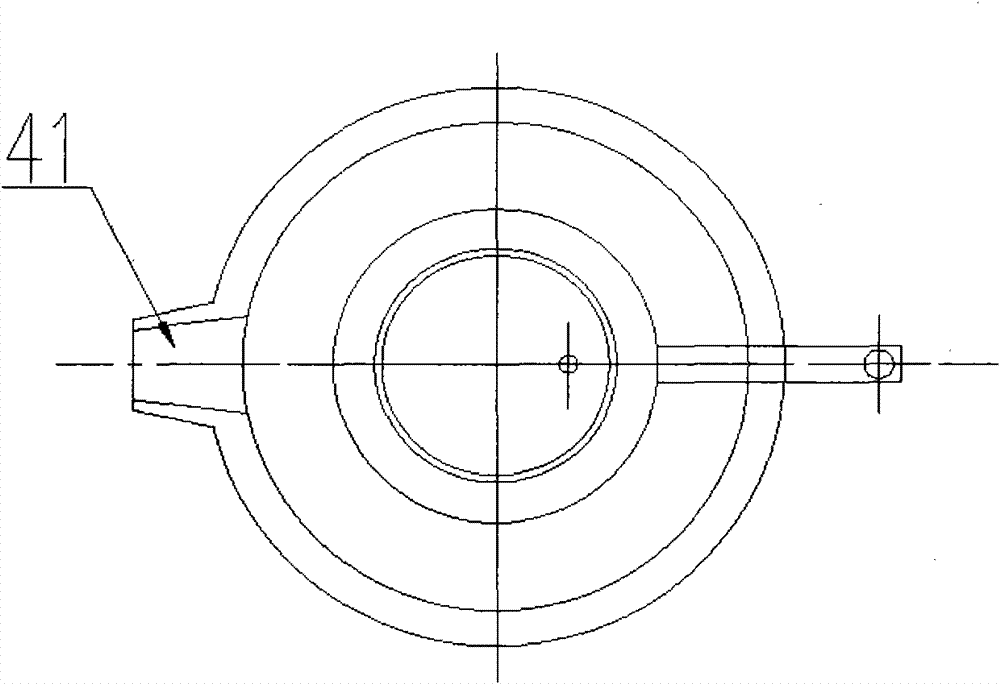

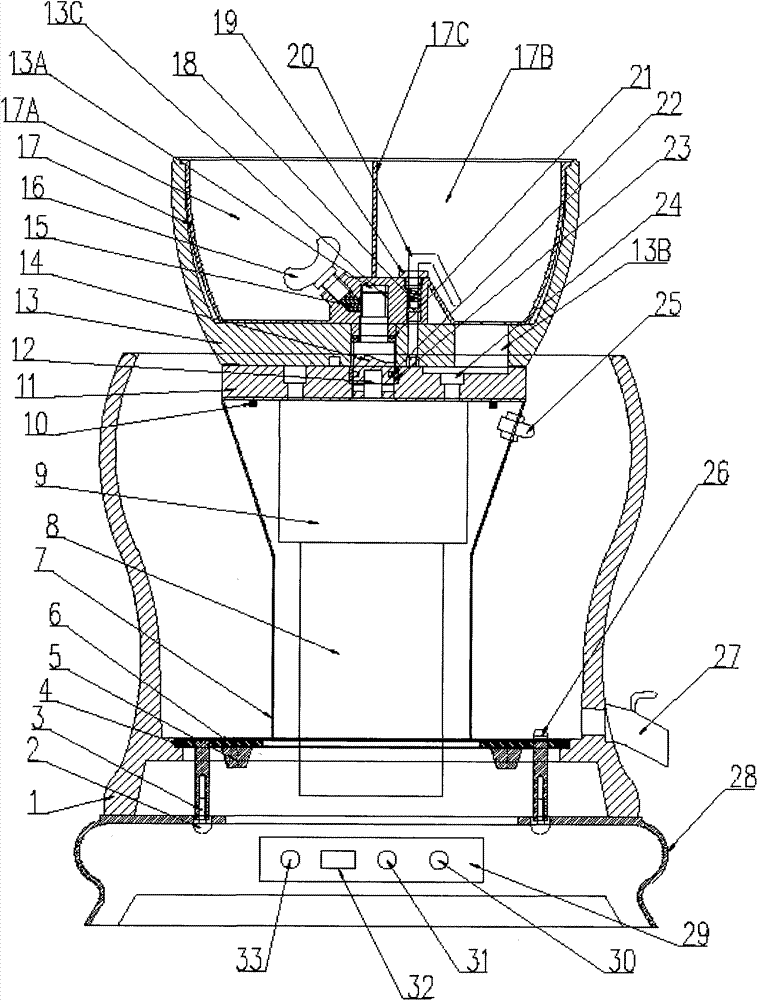

[0039] The technical solutions and embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. image 3 It is the front view of an automatic refiner, Figure 4 It is the top view of the upper millstone, Figure 5 It is the front view of the lower millstone pillar, Figure 6 It is the front view of the lower millstone, Figure 7 It is the top view of the lower millstone, Figure 8 is the front view of the connecting rod shaft, Figure 9 Is the electric control schematic diagram.

[0040]It can be seen from the figure that an automatic refiner consists of a base 28, a pulp storage tank 1, a lower millstone pillar 7, a motor 8, a reduction box 9, a lower millstone 11, an upper millstone 13, a connecting rod shaft 14, and a material tray 17. The anti-overflow sensor 25, temperature sensor 26, outlet 27, control circuit board 29, and common parts, standard parts, and circuit control devices are assembled; wherein, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com