Iron remover and iron removal method for cleaning materials transported in ports

A technology for transporting materials and iron removers, applied in the direction of high-gradient magnetic separators, etc., can solve the problems that ordinary iron removers cannot achieve the purpose of fine iron removal, large material particle size, thick material layer, etc., to reduce local overheating, temperature The effect of increasing uniformity and strengthening the magnetic force distribution area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-10 To describe in detail the iron remover for port transportation materials cleaning of the present invention, the following is only used as an example to illustrate, and those skilled in the art clearly know that as long as the method and system conform to the idea of the present invention, they all fall into the present invention; in addition, no The scope of protection of the present invention should only be limited to the specific parameters of the specific structure or components of the iron remover for cleaning materials transported in ports.

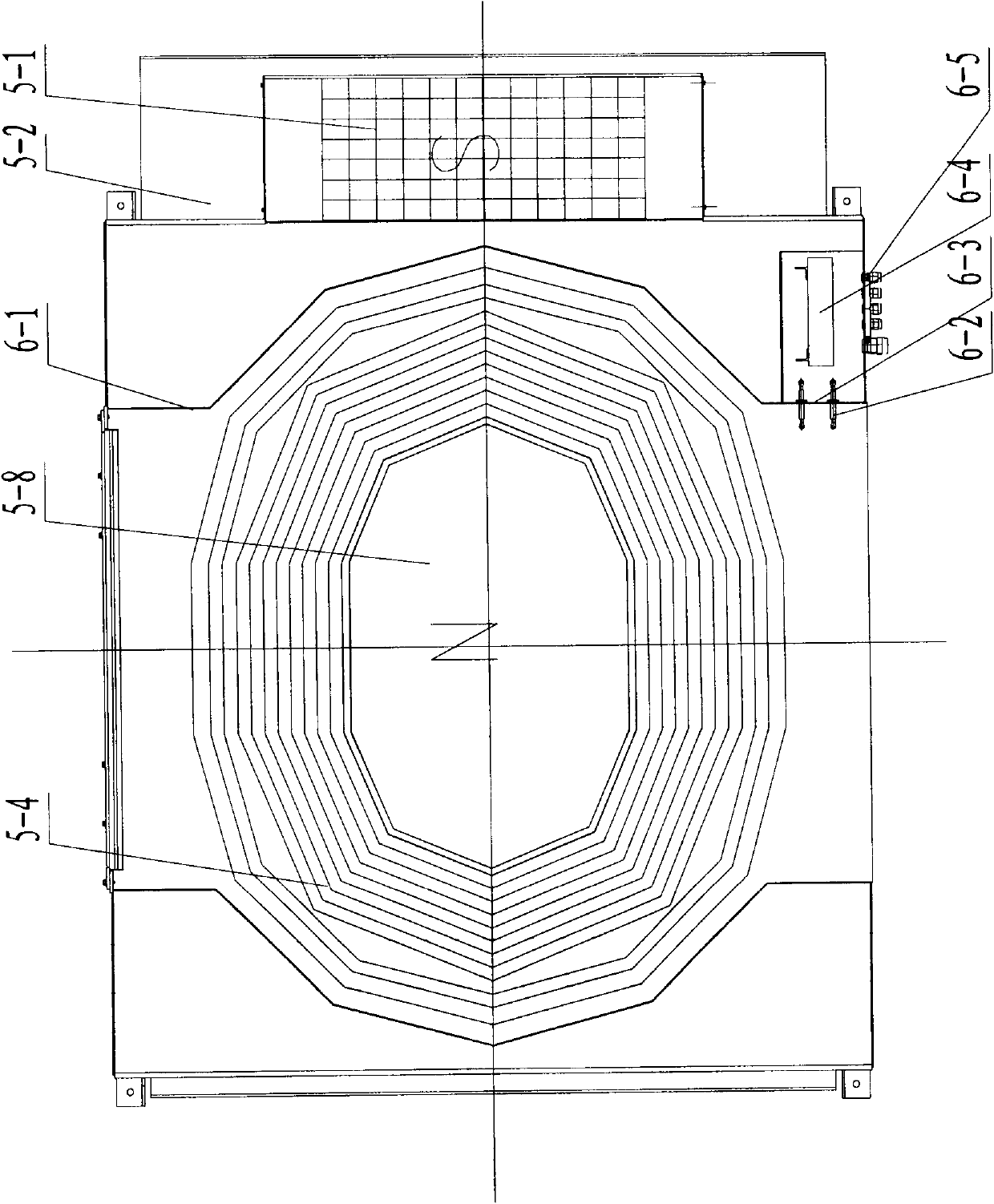

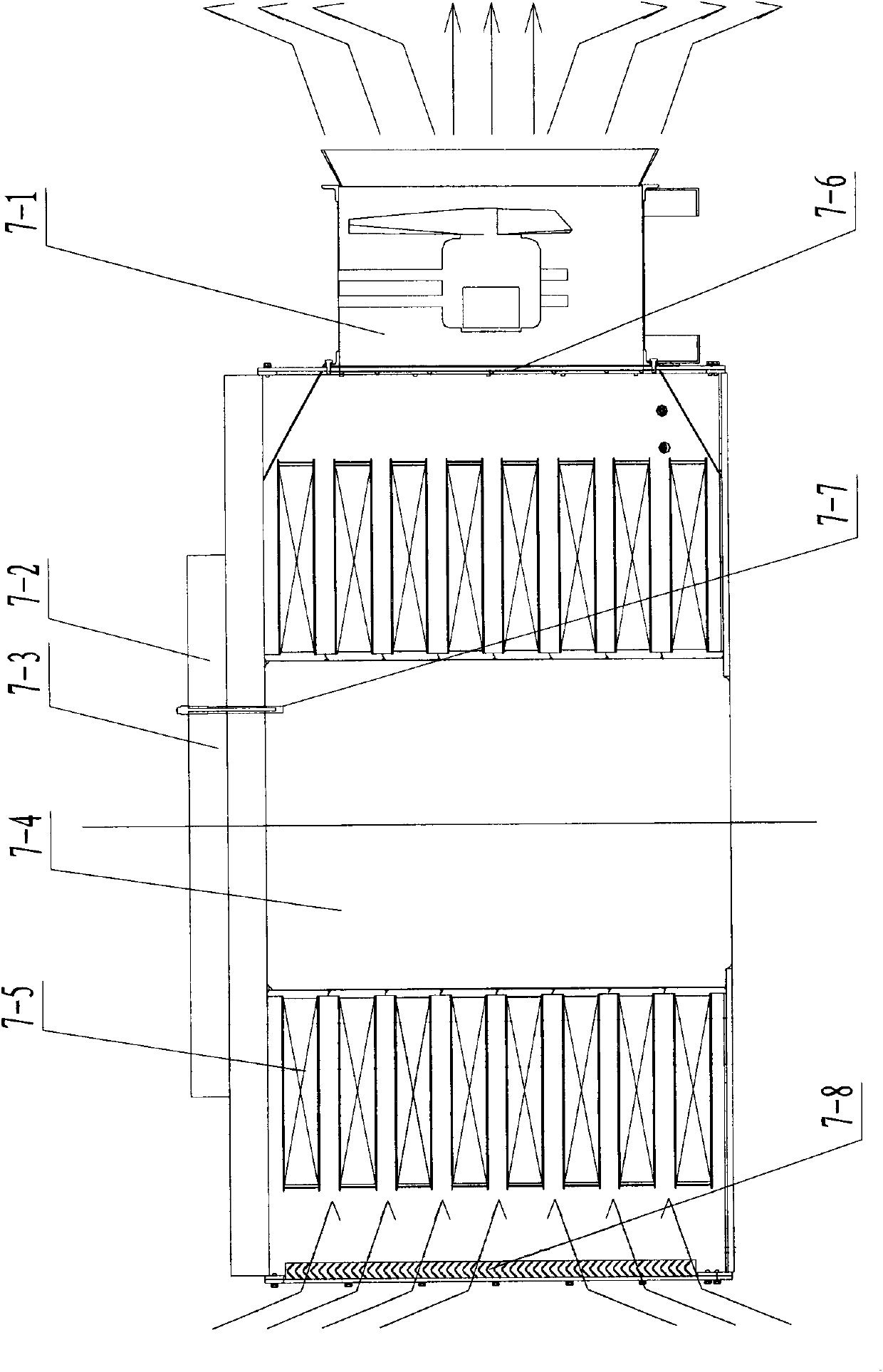

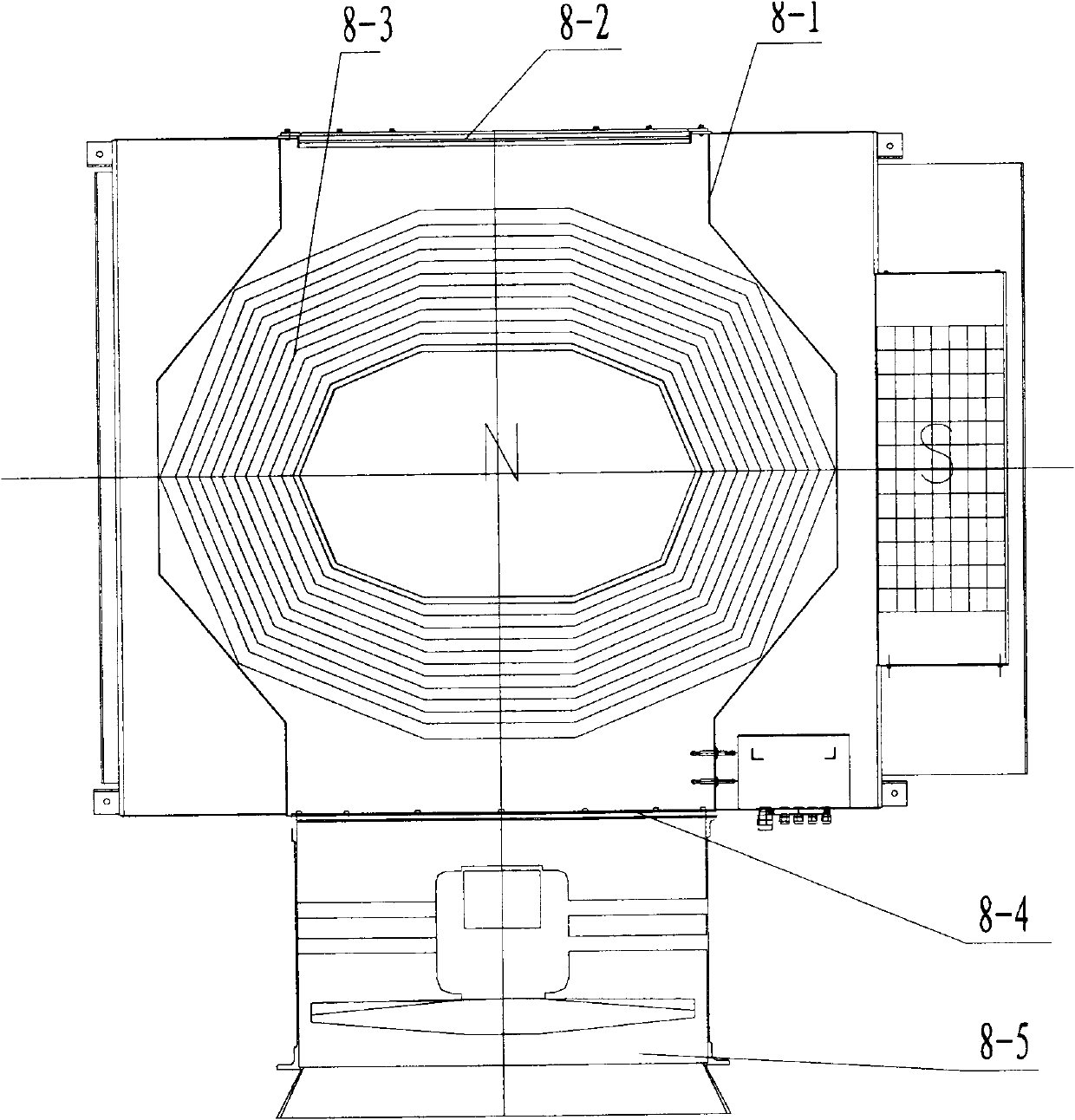

[0037] Such as figure 1 As shown, the iron remover for cleaning port transport materials of the present invention: the core part is a magnetic field magnetic system, which includes a high-gradient elliptical main magnetic system 1-13 and a bipolar magnetic field auxiliary magnetic system 1-14, and the magnetic field magnetic system generates The magnetic field realizes that the equipme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap