Electromagnetic valve

A solenoid valve and magnetic attraction technology, which is applied in the field of solenoid valves, can solve the problems of increasing the diameter of the coil and increasing the size of the solenoid valve, and achieve the effect of increasing the magnetic attraction force and improving the operation response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

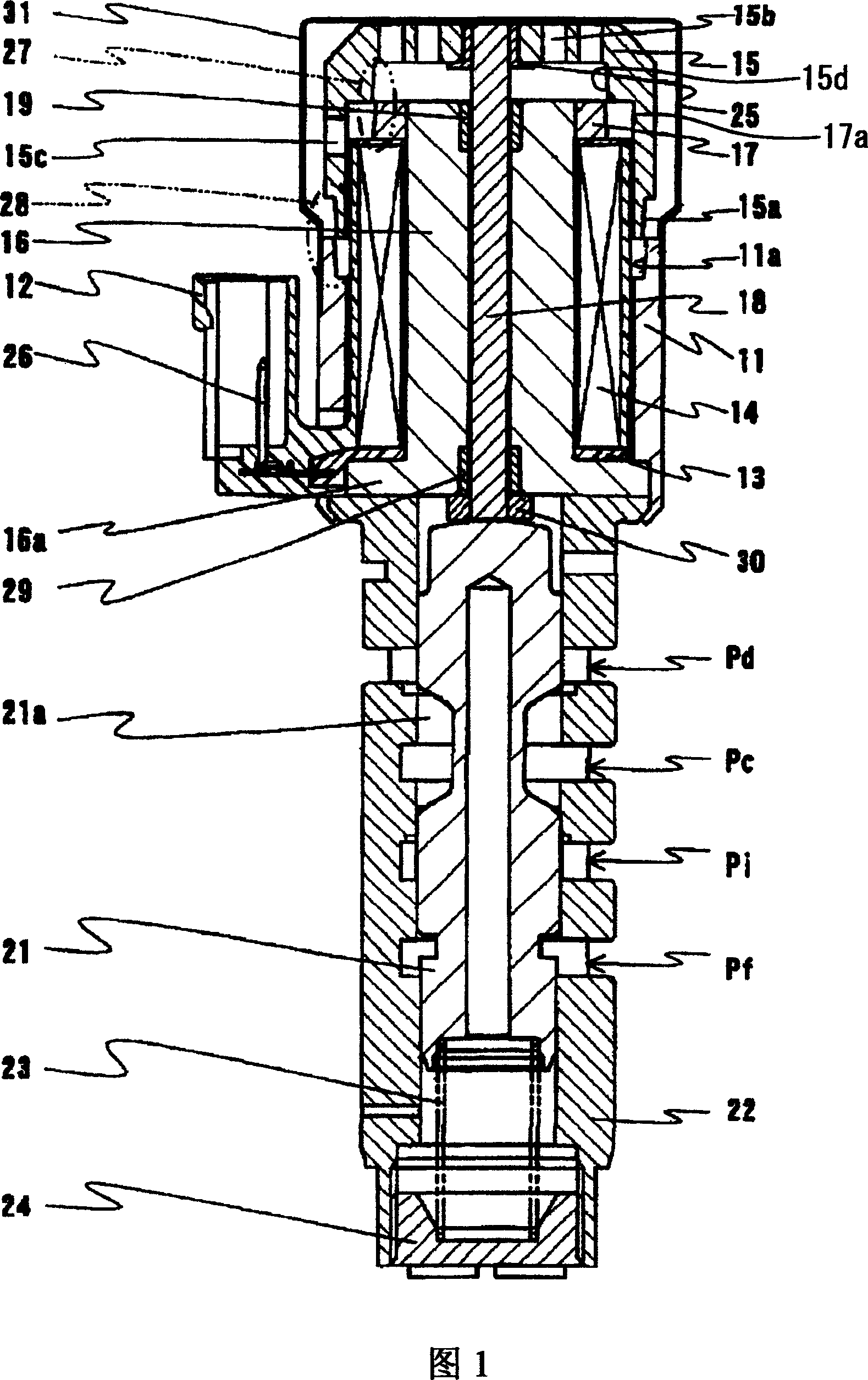

[0010] An embodiment of the present invention will be described below with reference to the accompanying drawings. A solenoid valve according to an embodiment of the present invention is shown in FIG. 1 . According to this embodiment, the solenoid valve is correspondingly a linear solenoid valve for a hydraulic control device which can realize feedback control.

[0011] As shown in FIG. 1 , a coil 14 wound on a bobbin 13 made of resin is housed in a case 11 . A connector 12 made of resin is fixed to the first end of the housing 11 . The connector 12 is electrically connected to the coil 14 and is integral with a terminal 26 for energizing the coil 14 . A stepped magnetic attraction portion 11 a whose wall becomes thinner is formed at the second end of the housing 11 .

[0012] A cylindrical front end yoke (ie, serving as a fixed iron core) 16 is built in the bobbin 13 and has a flange 16a at its first end on the terminal 26 side. An annular rear end yoke 17 is integrally p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com